W1683 Manual - Grizzly Industrial Inc.

W1683 Manual - Grizzly Industrial Inc.

W1683 Manual - Grizzly Industrial Inc.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Lubrication<br />

Since all bearings are sealed and permanently<br />

lubricated, leave them alone until they need to<br />

be replaced. Do not lubricate them.<br />

The Model <strong>W1683</strong> does need lubrication in other<br />

places.<br />

• Columns and Lead Screws — Remove dust<br />

covers for access. Lubricate columns weekly<br />

with light oil, and lubricate the four lead<br />

screws once a month with general purpose<br />

grease.<br />

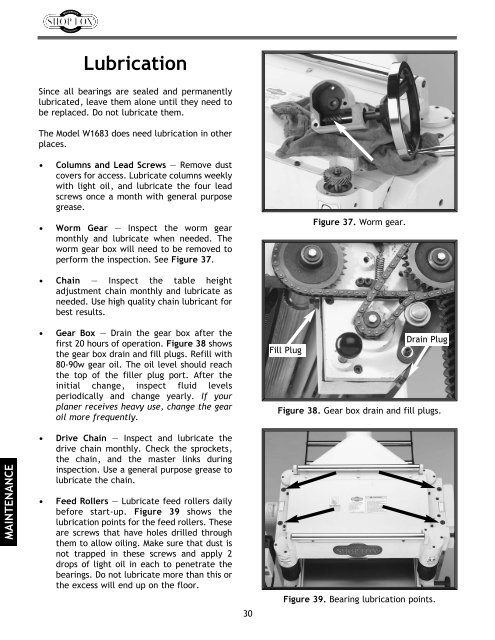

• Worm Gear — Inspect the worm gear<br />

monthly and lubricate when needed. The<br />

worm gear box will need to be removed to<br />

perform the inspection. See Figure 37.<br />

Figure 37. Worm gear.<br />

• Chain — Inspect the table height<br />

adjustment chain monthly and lubricate as<br />

needed. Use high quality chain lubricant for<br />

best results.<br />

MAINTENANCE<br />

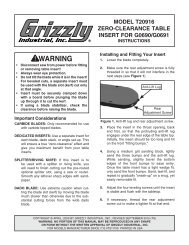

• Gear Box — Drain the gear box after the<br />

first 20 hours of operation. Figure 38 shows<br />

the gear box drain and fill plugs. Refill with<br />

80-90w gear oil. The oil level should reach<br />

the top of the filler plug port. After the<br />

initial change, inspect fluid levels<br />

periodically and change yearly. If your<br />

planer receives heavy use, change the gear<br />

oil more frequently.<br />

• Drive Chain — Inspect and lubricate the<br />

drive chain monthly. Check the sprockets,<br />

the chain, and the master links during<br />

inspection. Use a general purpose grease to<br />

lubricate the chain.<br />

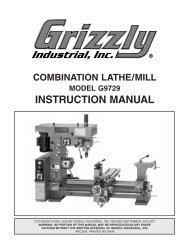

• Feed Rollers — Lubricate feed rollers daily<br />

before start-up. Figure 39 shows the<br />

lubrication points for the feed rollers. These<br />

are screws that have holes drilled through<br />

them to allow oiling. Make sure that dust is<br />

not trapped in these screws and apply 2<br />

drops of light oil in each to penetrate the<br />

bearings. Do not lubricate more than this or<br />

the excess will end up on the floor.<br />

30<br />

Drain Plug<br />

Fill Plug<br />

Figure 38. Gear box drain and fill plugs.<br />

Figure 39. Bearing lubrication points.