2011 Annual Report - Center for Integrated Nanotechnologies - Los ...

2011 Annual Report - Center for Integrated Nanotechnologies - Los ...

2011 Annual Report - Center for Integrated Nanotechnologies - Los ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Theory & Simulation of Nanoscale Phenomena Thrust<br />

Potential New Nanolithography Tool from<br />

Directed Assembly of Mixed Polymer Brushes<br />

Scientific Accomplishments: Top-down lithography is a<br />

well-established industrial technology that allows <strong>for</strong> the patterning<br />

of geometrical designs with nanometer-level precision<br />

and accuracy. Though conventional lithography has achieved<br />

the continual shrinkage of surface features, it is widely believed<br />

that fundamental limitations will soon be reached. These limitations<br />

could be overcome by combining molecular self-assembly<br />

with lithographic techniques in a process known as templated<br />

self-assembly. Most work in this area to date has focused on<br />

the use of self-assembling block copolymers. An alternative<br />

polymer system is a mixture of two different homopolymers<br />

that are covalently bonded to a substrate to produce a polymer<br />

“brush”. The two different polymers will prefer to phase separate<br />

from each other, but because of their covalent bond to the<br />

substrate, only micro-phase separation is possible, resulting<br />

in nanoscale self-assembled patterns. Mixed brushes have<br />

various advantages over diblock copolymers; in particular they<br />

could be grown on three-dimensional substrates and on a wider<br />

variety of substrates.<br />

Our idea was to use boundary interactions to orient these nanoscale<br />

assemblies into long range ordered patterns. Through<br />

a two-step polymerization scheme, micron-scale mixed polymer<br />

brush regions bordered by a region of pure polymer could be<br />

produced. We anticipate that the interaction with the pure polymer<br />

would direct the phase separation parallel to this interface<br />

by drawing the compatible polymer chains to the interface, <strong>for</strong>ming<br />

the first nanoscale domain in the phase separation pattern.<br />

To demonstrate that this ordering mechanism in mixed polymer<br />

brushes is possible, we carried out theoretical simulations with<br />

CINT Users Su-Mi Hur and Glenn Fredrickson at the University<br />

of Cali<strong>for</strong>nia, Santa Barbara. We calculated the morphology of<br />

a mixed polymer brush consisting of two polymers (A and B) of<br />

the same length, both grafted to a hard substrate, using selfconsistent<br />

field theory. When the brush is not confined laterally,<br />

a disordered pattern <strong>for</strong>ms, consisting of regions rich in either<br />

polymer A or B. However, when a pure brush region of polymer<br />

A is introduced, it templates the assembly of domains of<br />

polymer A next to the pure brush region. Slowly annealing the<br />

system leads to a regular pattern of nanoscale stripes. The calculations<br />

also show that the pattern is robust to perturbations,<br />

such as roughness in the pure brush region.<br />

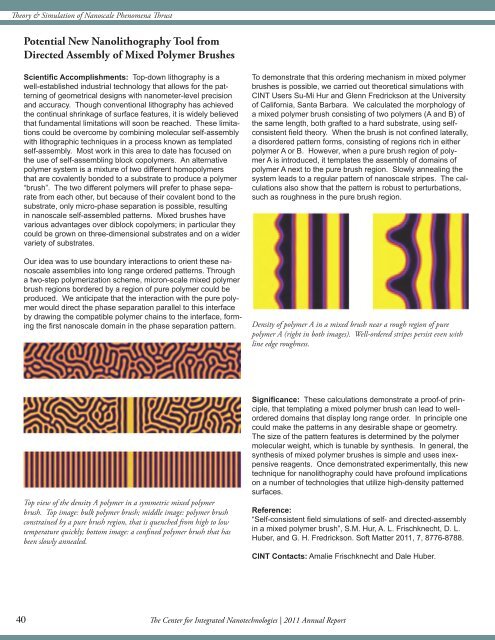

Density of polymer A in a mixed brush near a rough region of pure<br />

polymer A (right in both images). Well-ordered stripes persist even with<br />

line edge roughness.<br />

Top view of the density A polymer in a symmetric mixed polymer<br />

brush. Top image: bulk polymer brush; middle image: polymer brush<br />

constrained by a pure brush region, that is quenched from high to low<br />

temperature quickly; bottom image: a confined polymer brush that has<br />

been slowly annealed.<br />

Significance: These calculations demonstrate a proof-of principle,<br />

that templating a mixed polymer brush can lead to wellordered<br />

domains that display long range order. In principle one<br />

could make the patterns in any desirable shape or geometry.<br />

The size of the pattern features is determined by the polymer<br />

molecular weight, which is tunable by synthesis. In general, the<br />

synthesis of mixed polymer brushes is simple and uses inexpensive<br />

reagents. Once demonstrated experimentally, this new<br />

technique <strong>for</strong> nanolithography could have profound implications<br />

on a number of technologies that utilize high-density patterned<br />

surfaces.<br />

Reference:<br />

“Self-consistent field simulations of self- and directed-assembly<br />

in a mixed polymer brush”, S.M. Hur, A. L. Frischknecht, D. L.<br />

Huber, and G. H. Fredrickson. Soft Matter <strong>2011</strong>, 7, 8776-8788.<br />

CINT Contacts: Amalie Frischknecht and Dale Huber.<br />

40<br />

40The <strong>Center</strong> <strong>for</strong> <strong>Integrated</strong> <strong>Nanotechnologies</strong> | <strong>2011</strong> <strong>Annual</strong> <strong>Report</strong>