1 - Komet Scandinavia AB

1 - Komet Scandinavia AB

1 - Komet Scandinavia AB

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

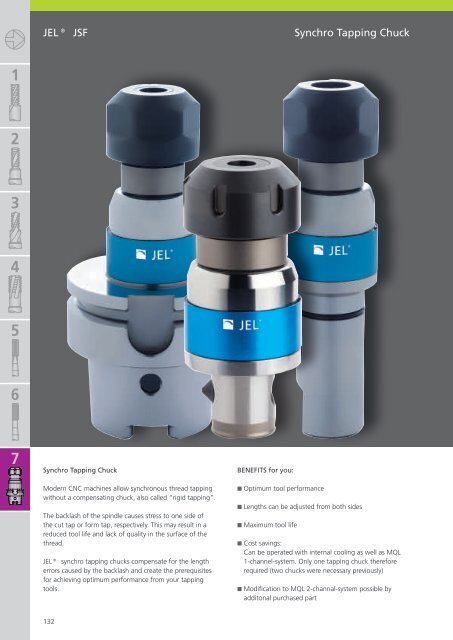

JEL® JSF<br />

Synchro Tapping Chuck<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

Synchro Tapping Chuck<br />

Modern CNC machines allow synchronous thread tapping<br />

without a compensating chuck, also called “rigid tapping”.<br />

The backlash of the spindle causes stress to one side of<br />

the cut tap or form tap, respectively. This may result in a<br />

reduced tool life and lack of quality in the surface of the<br />

thread.<br />

JEL® synchro tapping chucks compensate for the length<br />

errors caused by the backlash and create the prerequisites<br />

for achieving optimum performance from your tapping<br />

tools.<br />

BENEFITS for you:<br />

K Optimum tool performance<br />

K Lengths can be adjusted from both sides<br />

K Maximum tool life<br />

K Cost savings:<br />

Can be operated with internal cooling as well as MQL<br />

1-channel-system. Only one tapping chuck therefore<br />

required (two chucks were necessary previously)<br />

K Modification to MQL 2-channal-system possible by<br />

additonal purchased part<br />

132