- Page 1 and 2:

KomPass - Threading

- Page 3 and 4:

Process for producing internal thre

- Page 5 and 6:

Index General information Tool sele

- Page 7 and 8:

JEL® Producing Internal Threads Pr

- Page 9 and 10:

JEL® Tool Selection Thread milling

- Page 11 and 12:

JEL® Tool Selection Taps TAREX TAR

- Page 13 and 14:

JEL® Tool Selection Roll form taps

- Page 15 and 16:

Thread Milling Tool MKG Page 1 Thre

- Page 17 and 18:

M 2,0×D JEL® MKG Thread milling t

- Page 19 and 20:

UNC 2,0×D JEL® MKG Thread milling

- Page 21 and 22:

G 2,0×D JEL® MKG Thread milling t

- Page 23 and 24:

MF 1,5×D JEL® MKG XH Thread milli

- Page 25 and 26:

JEL® Thread Milling Tool 1. Proble

- Page 27 and 28:

Thread Milling Tool MGF, UMGF Page

- Page 29 and 30:

JEL® UMGF Thread engagements 1 D1

- Page 31 and 32:

M 2,0×D 2,5×D 3,0×D JEL® MGF Th

- Page 33 and 34:

MF 2,0×D JEL® MGF Thread milling

- Page 35 and 36:

UNF 1,5×D 2,0×D JEL® MGF Thread

- Page 37 and 38:

G 1,5×D 2,0×D JEL® MGF Thread mi

- Page 39 and 40:

MF 1,5×D 2,0×D JEL® MGF XS Threa

- Page 41 and 42:

M JEL® MGF XH Micro 1,5×D l2.7 l2

- Page 43 and 44:

MF 1,5×D JEL® MGF XH Thread milli

- Page 45 and 46:

MF 2,0×D JEL® MGF PKD for metric

- Page 47 and 48:

MF 2,0×D JEL® UMGF Thread milling

- Page 49 and 50:

JEL® Thread Milling Tool 1. Proble

- Page 51 and 52:

Drill Thread Milling Tool BGF, UBGF

- Page 53 and 54:

JEL® UBGF Thread engagements 1 140

- Page 55 and 56:

M 2,0×D JEL® BGF Drill thread mil

- Page 57 and 58:

M 1,5×D 2,0×D JEL® BGF Drill thr

- Page 59 and 60:

MF 1,5×D 2,0×D JEL® BGF Drill th

- Page 61 and 62:

UNF 1,5×D 2,0×D JEL® BGF Drill t

- Page 63 and 64:

M JEL® BGF 1,5×D 2,0×D l10 l2.7

- Page 65 and 66:

M 1,5×D 2,0×D 2,5×D JEL® BGF NZ

- Page 67 and 68:

MF 2,0×D JEL® UBGF Drill thread m

- Page 69 and 70:

UNF 2,0×D JEL® UBGF Drill thread

- Page 71 and 72:

M 2,0×D 3,0×D JEL® DBGF Direct c

- Page 73 and 74:

1. 2. JEL® Drill Thread Milling To

- Page 75 and 76:

BENEFITS for you: K One and the sam

- Page 77 and 78:

JEL® TOMILL CUT Holder 1 l1 l2 l3

- Page 79 and 80:

JEL® XAM 1 2 3 X 21,10 mm (20.22)

- Page 81 and 82:

M, MF JEL® GWF TOMILL Thread milli

- Page 83 and 84:

UN JEL® GWF TOMILL Thread milling

- Page 85 and 86:

NPT, NPTF JEL® GWF TOMILL Thread m

- Page 87 and 88:

M, MF JEL® GWF TOMILL Thread milli

- Page 89 and 90:

G JEL® GWF TOMILL Thread milling t

- Page 91 and 92:

JEL® Thread Milling Tool Material

- Page 93 and 94:

JEL® Thread Milling Tool 1. Proble

- Page 95 and 96:

Machining threads JEL® tap drills

- Page 97 and 98:

M JEL® TINIB, FEDUB HSS-PM Taps fo

- Page 99 and 100:

M JEL® FEDUC HSS-PM Taps for metri

- Page 101 and 102:

KOMET SERVICE® Comprehensive addit

- Page 103 and 104: M JEL® TAREX HSS-E Taps for metric

- Page 105 and 106: M JEL® SIREX SR l2 Solid Carbide T

- Page 107 and 108: M JEL® SIREX XH Solid Carbide Taps

- Page 109 and 110: MF JEL® SIREX SR Solid Carbide Tap

- Page 111 and 112: 1. Oversized thread • wrong tools

- Page 113 and 114: For standard tools customers can ge

- Page 115 and 116: M JEL® MOREX N l2 HSS-E Roll form

- Page 117 and 118: M JEL® MOREX Solid carbide roll fo

- Page 119 and 120: M JEL® MOREX N Solid carbide roll

- Page 121 and 122: M JEL® MOREX S N Solid carbide rol

- Page 123 and 124: MF JEL® MOREX S N Solid carbide ro

- Page 125 and 126: M JEL® MOREX N HML l2 HSS-E Roll f

- Page 127 and 128: MF JEL® MOREX HML HSS-E Roll form

- Page 129 and 130: MF JEL® MOREX R HSS-E Roll form ta

- Page 131 and 132: 1. 2. Thread too tigh • tolerance

- Page 133 and 134: Synchro Tapping Chuck HSK-A adaptor

- Page 135 and 136: JEL® JSF Synchro Tapping Chuck wit

- Page 137 and 138: JEL® Collet for Synchro Tapping Ch

- Page 139 and 140: Boring, counterboring and thread mi

- Page 141 and 142: JEL® VABOS EASY Holder with HSK-A

- Page 143 and 144: Fax to +49 7143 373233 JEL® VABOS

- Page 145 and 146: Index Technical Informations Specia

- Page 147 and 148: JEL® Special Solutions 1 PCD speci

- Page 149 and 150: JEL® Tap drill diameters for mille

- Page 151 and 152: M Metric thread Formed threads JEL

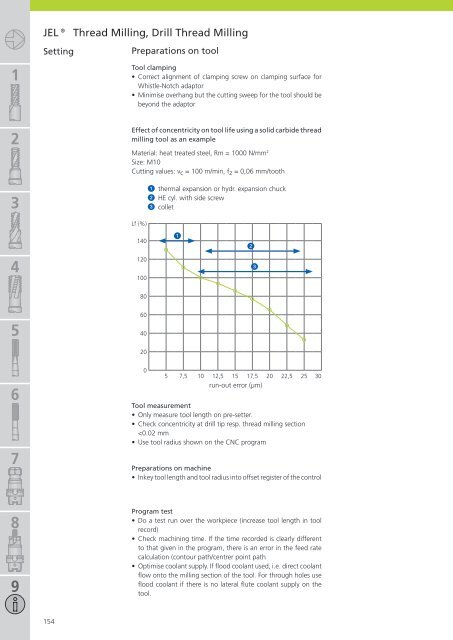

- Page 153: Machining task: Thread: M10, depth

- Page 157 and 158: JEL® Torque calculations for tappi

- Page 159 and 160: Machine requirements: To carry out

- Page 161 and 162: JEL® Cylindrical Shanks for carbid

- Page 163 and 164: Fax Order +49 7143 373233 KomPass -

- Page 165 and 166: 1 From stock or individually manufa

- Page 167 and 168: 1 2 A 3 B C D E 4 F G H 5 I J K L 6

- Page 169 and 170: Numerical Index 1802 ... Order No.

- Page 171 and 172: Numerical Index 8087 ... Order No.

- Page 173 and 174: Numerical Index 8894 ... 8897 ... 8

- Page 175 and 176: Notes 1 2 3 4 5 6 7 8 9 175

- Page 177 and 178: TOOLS PLUS IDEAS - a PLUS for our c

- Page 179 and 180: Outside Europe Egypt ZAHRANCO, ENGI