Materials Section - City of Xenia

Materials Section - City of Xenia

Materials Section - City of Xenia

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

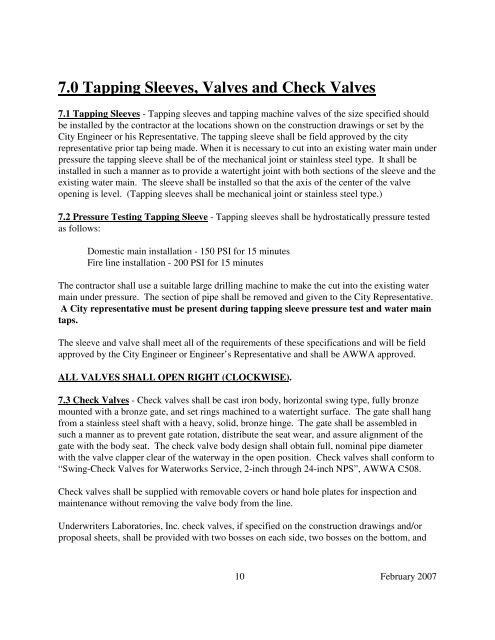

7.0 Tapping Sleeves, Valves and Check Valves<br />

7.1 Tapping Sleeves - Tapping sleeves and tapping machine valves <strong>of</strong> the size specified should<br />

be installed by the contractor at the locations shown on the construction drawings or set by the<br />

<strong>City</strong> Engineer or his Representative. The tapping sleeve shall be field approved by the city<br />

representative prior tap being made. When it is necessary to cut into an existing water main under<br />

pressure the tapping sleeve shall be <strong>of</strong> the mechanical joint or stainless steel type. It shall be<br />

installed in such a manner as to provide a watertight joint with both sections <strong>of</strong> the sleeve and the<br />

existing water main. The sleeve shall be installed so that the axis <strong>of</strong> the center <strong>of</strong> the valve<br />

opening is level. (Tapping sleeves shall be mechanical joint or stainless steel type.)<br />

7.2 Pressure Testing Tapping Sleeve - Tapping sleeves shall be hydrostatically pressure tested<br />

as follows:<br />

Domestic main installation - 150 PSI for 15 minutes<br />

Fire line installation - 200 PSI for 15 minutes<br />

The contractor shall use a suitable large drilling machine to make the cut into the existing water<br />

main under pressure. The section <strong>of</strong> pipe shall be removed and given to the <strong>City</strong> Representative.<br />

A <strong>City</strong> representative must be present during tapping sleeve pressure test and water main<br />

taps.<br />

The sleeve and valve shall meet all <strong>of</strong> the requirements <strong>of</strong> these specifications and will be field<br />

approved by the <strong>City</strong> Engineer or Engineer’s Representative and shall be AWWA approved.<br />

ALL VALVES SHALL OPEN RIGHT (CLOCKWISE).<br />

7.3 Check Valves - Check valves shall be cast iron body, horizontal swing type, fully bronze<br />

mounted with a bronze gate, and set rings machined to a watertight surface. The gate shall hang<br />

from a stainless steel shaft with a heavy, solid, bronze hinge. The gate shall be assembled in<br />

such a manner as to prevent gate rotation, distribute the seat wear, and assure alignment <strong>of</strong> the<br />

gate with the body seat. The check valve body design shall obtain full, nominal pipe diameter<br />

with the valve clapper clear <strong>of</strong> the waterway in the open position. Check valves shall conform to<br />

“Swing-Check Valves for Waterworks Service, 2-inch through 24-inch NPS”, AWWA C508.<br />

Check valves shall be supplied with removable covers or hand hole plates for inspection and<br />

maintenance without removing the valve body from the line.<br />

Underwriters Laboratories, Inc. check valves, if specified on the construction drawings and/or<br />

proposal sheets, shall be provided with two bosses on each side, two bosses on the bottom, and<br />

10 February 2007