Before - Dorr-Oliver Alumni

Before - Dorr-Oliver Alumni

Before - Dorr-Oliver Alumni

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

·'~'L .ASY 'OFF<br />

. , .' - . .<br />

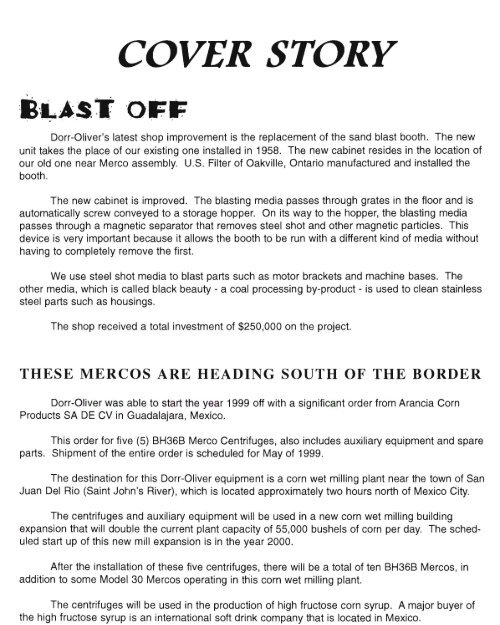

COVER STORY <br />

<strong>Dorr</strong>-<strong>Oliver</strong>'s latest shop improvement is the replacement of the sand blast booth. The new<br />

unit takes the place of our existing one installed in 1958. The new cabinet resides in the location of<br />

our old one near Merco assembly. U.S. Filter of Oakville, Ontario manufactured and installed the<br />

booth.<br />

The new cabinet is improved. The blasting media passes through grates in the floor and is<br />

automatically screw conveyed to a storage hopper. On its way to the hopper, the blasting media<br />

passes through a magnetic separator that removes steel shot and other magnetic particles. This<br />

device is very important because it allows the booth to be run with a different kind of media without<br />

having to completely remove the first.<br />

We use steel shot media to blast parts such as motor brackets and machine bases. The<br />

other media, which is called black beauty - a coal processing by-product - is used to clean stainless<br />

steel parts such as housings.<br />

The shop received a total investment of $250,000 on the project.<br />

THESE MERCOS ARE HEADING SOUTH OF THE BORDER<br />

<strong>Dorr</strong>-<strong>Oliver</strong> was able to start the year 1999 off with a significant order from Arancia Corn<br />

Products SA DE CV in Guadalajara, Mexico.<br />

This order for five (5) BH36B Merco Centrifuges, also includes auxiliary equipment and spare<br />

parts. Shipment of the entire order is scheduled for May of 1999.<br />

The destination for this <strong>Dorr</strong>-<strong>Oliver</strong> equipment is a corn wet milling plant near the town of San<br />

Juan Del Rio (Saint John's River) , which is located approximately two hours north of Mexico City.<br />

The centrifuges and auxiliary equipment will be used in a new corn wet milling building<br />

expansion that will double the current plant capacity of 55,000 bushels of corn per day. The scheduled<br />

start up of this new mill expansion is in the year 2000.<br />

After the installation of these five centrifuges, there will be a total of ten BH36B Mercos, in<br />

addition to some Model 30 Mercos operating in this corn wet milling plant.<br />

The centrifuges will be used in the production of high fructose corn syrup. A major buyer of<br />

the high fructose syrup is an international soft drink company that is located in Mexico.