investigation of a prototype industrial gas turbine combustor using ...

investigation of a prototype industrial gas turbine combustor using ...

investigation of a prototype industrial gas turbine combustor using ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

3. Experimental setups<br />

3.1 The laminar flame speed setup<br />

The laminar flame speed for a range <strong>of</strong> fuels was investigated, to<br />

obtain a better understanding <strong>of</strong> how well different fuels burn (Table<br />

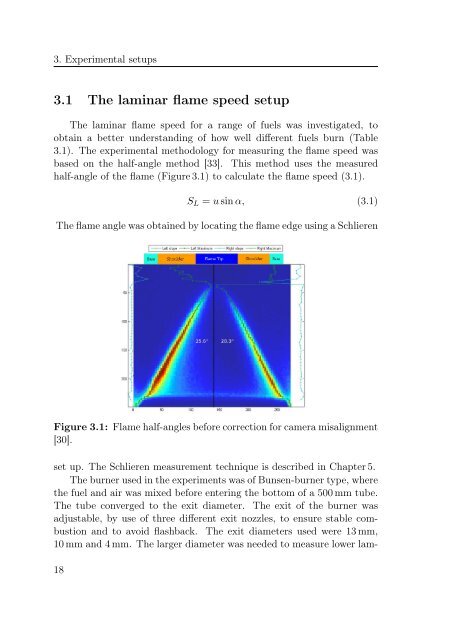

3.1). The experimental methodology for measuring the flame speed was<br />

based on the half-angle method [33]. This method uses the measured<br />

half-angle <strong>of</strong> the flame (Figure 3.1) to calculate the flame speed (3.1).<br />

S L = u sin α, (3.1)<br />

The flame angle was obtained by locating the flame edge <strong>using</strong> a Schlieren<br />

Figure 3.1: Flame half-angles before correction for camera misalignment<br />

[30].<br />

set up. The Schlieren measurement technique is described in Chapter 5.<br />

The burner used in the experiments was <strong>of</strong> Bunsen-burner type, where<br />

the fuel and air was mixed before entering the bottom <strong>of</strong> a 500 mm tube.<br />

The tube converged to the exit diameter. The exit <strong>of</strong> the burner was<br />

adjustable, by use <strong>of</strong> three different exit nozzles, to ensure stable combustion<br />

and to avoid flashback. The exit diameters used were 13 mm,<br />

10 mm and 4 mm. The larger diameter was needed to measure lower lam-<br />

18