investigation of a prototype industrial gas turbine combustor using ...

investigation of a prototype industrial gas turbine combustor using ...

investigation of a prototype industrial gas turbine combustor using ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

3. Experimental setups<br />

3.4 The pressurized full burner setup<br />

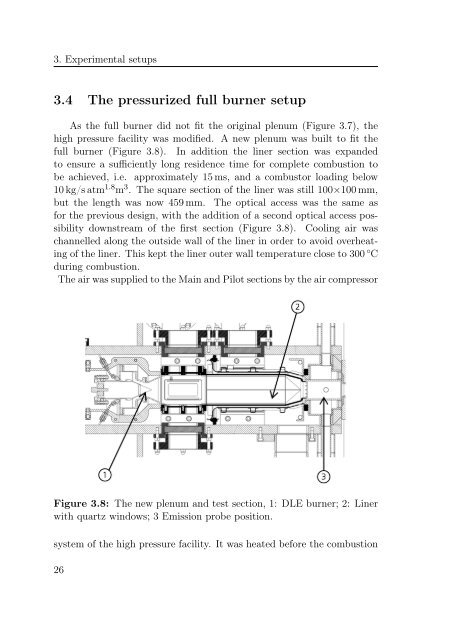

As the full burner did not fit the original plenum (Figure 3.7), the<br />

high pressure facility was modified. A new plenum was built to fit the<br />

full burner (Figure 3.8). In addition the liner section was expanded<br />

to ensure a sufficiently long residence time for complete combustion to<br />

be achieved, i.e. approximately 15 ms, and a <strong>combustor</strong> loading below<br />

10 kg/s atm 1.8 m 3 . The square section <strong>of</strong> the liner was still 100×100 mm,<br />

but the length was now 459 mm. The optical access was the same as<br />

for the previous design, with the addition <strong>of</strong> a second optical access possibility<br />

downstream <strong>of</strong> the first section (Figure 3.8). Cooling air was<br />

channelled along the outside wall <strong>of</strong> the liner in order to avoid overheating<br />

<strong>of</strong> the liner. This kept the liner outer wall temperature close to 300 ◦ C<br />

during combustion.<br />

The air was supplied to the Main and Pilot sections by the air compressor<br />

Figure 3.8: The new plenum and test section, 1: DLE burner; 2: Liner<br />

with quartz windows; 3 Emission probe position.<br />

system <strong>of</strong> the high pressure facility. It was heated before the combustion<br />

26