Management of Lifting Operations and Equipment - to return to the ...

Management of Lifting Operations and Equipment - to return to the ...

Management of Lifting Operations and Equipment - to return to the ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

SM-WI-45-03<br />

a<br />

Page 5 <strong>of</strong> 15<br />

<strong>Management</strong> <strong>of</strong> <strong>Lifting</strong> <strong>Operations</strong> <strong>and</strong> <strong>Equipment</strong><br />

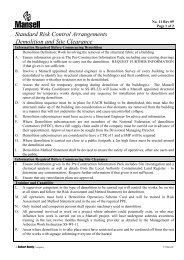

Table 1 – Lift Planning Key Considerations <strong>and</strong> Requirements<br />

Key Consideration Requirements Control Ref.<br />

Ground conditions<br />

<strong>and</strong> bearing<br />

capacity<br />

<strong>Lifting</strong> <strong>Equipment</strong><br />

Capacity (load /<br />

reach)<br />

<strong>Equipment</strong><br />

Condition, Age,<br />

Maintenance, Test /<br />

Inspection Regime<br />

Site Access<br />

(dimensions <strong>and</strong><br />

ground conditions)<br />

Lay down Areas<br />

Care <strong>of</strong> Materials<br />

<strong>Lifting</strong> Points<br />

Slinging Practice<br />

Segregation <strong>of</strong><br />

<strong>Lifting</strong> Zone<br />

Wind Speed<br />

Appointment <strong>of</strong><br />

Competent People<br />

An assessment <strong>of</strong> ground conditions, including load bearing<br />

capacities must be made through <strong>the</strong> TWC <strong>and</strong> APL for any<br />

equipment transferring load <strong>to</strong> <strong>the</strong> ground.<br />

Load spreading mats must be appropriately specified in <strong>the</strong><br />

Lift Plan.<br />

Checks must be made for underground voids <strong>and</strong> services<br />

which may collapse.<br />

The capacity <strong>of</strong> lifting equipment must be adequate for <strong>the</strong><br />

load <strong>and</strong> reach required. Therefore, <strong>the</strong> weight <strong>of</strong> each item<br />

<strong>to</strong> be lifted must be identified.<br />

Plant <strong>and</strong> equipment must be maintained with tests,<br />

thorough examinations, inspections <strong>and</strong> maintenance at<br />

intervals as specified by <strong>the</strong> manufacturer <strong>and</strong> legislation.<br />

The route on<strong>to</strong> site must be assessed <strong>to</strong> confirm that lifting<br />

plant can safely access without causing damage <strong>to</strong> roads,<br />

pavements or o<strong>the</strong>r existing features.<br />

Lay down areas must be adequately prepared (firm <strong>and</strong><br />

level) <strong>and</strong> <strong>of</strong> sufficient size e.g. it must not become<br />

necessary <strong>to</strong> walk on steel.<br />

Where materials are susceptible <strong>to</strong> damage through lifting<br />

<strong>and</strong> stacking <strong>the</strong> Lift Plan <strong>and</strong> RAMS must specify controls<br />

necessary <strong>to</strong> protect <strong>the</strong> materials e.g. pre-cast floor planks<br />

must be supported in a particular way when stacked on site<br />

<strong>to</strong> avoid cracking <strong>and</strong> subsequent failure when next lifted.<br />

<strong>Lifting</strong> points must be identified in <strong>the</strong> lifting plan <strong>and</strong><br />

where reasonably practicable designed in.<br />

<strong>Lifting</strong> points on modular or precast products must be<br />

designed <strong>and</strong> prefabricated in.<br />

Slinging arrangements must be specified in <strong>the</strong> Lift Plan in<br />

order that loads are secure <strong>and</strong> stable, <strong>and</strong> so that nei<strong>the</strong>r <strong>the</strong><br />

load nor lifting equipment is damaged. The need for lifting<br />

beams must be considered.<br />

Those not involved in <strong>the</strong> lift must be excluded from <strong>the</strong><br />

lifting zone. Alternative access routes must be detailed in<br />

<strong>the</strong> Lift Plan or RAMS where required.<br />

The maximum safe wind speed for <strong>the</strong> lifting operation<br />

must be specified in <strong>the</strong> Lift Plan <strong>and</strong> a means <strong>of</strong> measuring<br />

wind speed (anemometer) available near <strong>the</strong> point <strong>of</strong> work.<br />

The Lift Plan must confirm <strong>the</strong> required competent<br />

personnel required <strong>to</strong> execute <strong>the</strong> lift safely, in accordance<br />

with <strong>the</strong> <strong>Lifting</strong> Plan.<br />

<br />

<br />

<br />

<br />

<br />

<br />

CS = Control Section<br />

Temporary Works<br />

(SS-WI-23)<br />

Working Platform<br />

WI (SM-WI-46)<br />

Figure 1<br />

Utility Avoidance,<br />

Excavation & Road<br />

Work (SM-WI-56)<br />

Crane Lift Plan<br />

(SM-FM-41)<br />

Non-Crane Lift Plan<br />

(SS-FM-53)<br />

CS1<br />

CS2<br />

Manufacturer<br />

information.<br />

CS1<br />

CS2<br />

Manufacturer<br />

Information<br />

Schedule <strong>of</strong><br />

Common <strong>Lifting</strong><br />

Techniques<br />

(SS-WI-22)<br />

CS1<br />

A Balfour Bea~y Company Uncontrolled when downloaded or printed © Mansell