July / August - Minnesota Precision Manufacturing Association

July / August - Minnesota Precision Manufacturing Association

July / August - Minnesota Precision Manufacturing Association

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Five years ago, Rudolph Technologies<br />

began positioning itself for rapid growth.<br />

The company planned to expand its<br />

product line and double its sales.<br />

There was one problem, however.<br />

Rudolph Technologies couldn’t count<br />

on its main supplier to keep up.<br />

Based in Flanders, New Jersey,<br />

Rudolph Technologies sells equipment<br />

that inspects computer wafers before<br />

they are turned into microchips.<br />

Such equipment requires large, sturdy,<br />

metal frames. But the company<br />

supplying those frames hadn’t been<br />

meeting quality and delivery standards.<br />

So Rudolph Technologies turned to<br />

Checker Machine in New Hope.<br />

Checker Machine specializes in<br />

fabricating large, turnkey frames<br />

and parts, some as heavy as 20,000<br />

pounds. Once it began supplying<br />

Rudolph Technologies with the frames<br />

it needed for its inspection equipment,<br />

quality was no longer an issue. Neither<br />

was flexibility. As a result, Rudolph<br />

Technologies was able to grow from<br />

$60 million to $120 million in five years.<br />

“We were impressed with Checker’s<br />

quality and employees from the start,”<br />

said Rudolph Technologies Purchasing<br />

Manager Kathy Kelly. “Even the shop<br />

itself was in line with what we needed.”<br />

<br />

Checker Machine is a job shop that<br />

specializes in large capacity machining<br />

and welding, such as frames for wind<br />

tunnels, steel boxes for turbines and<br />

large parts for printing presses. From<br />

design to fabrication, Checker Machine<br />

handles the entire spectrum<br />

of production.<br />

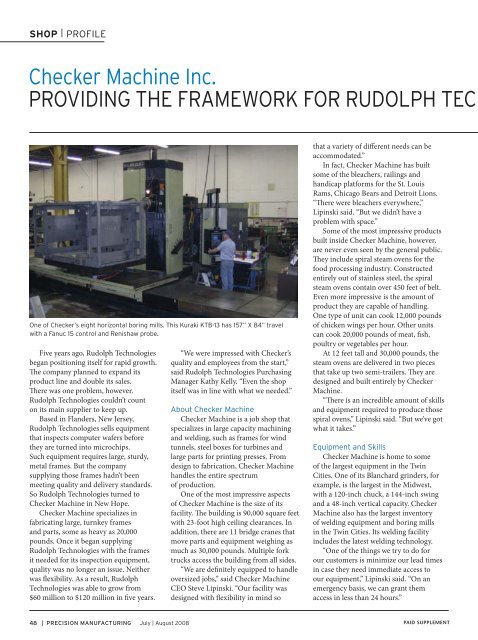

One of the most impressive aspects<br />

of Checker Machine is the size of its<br />

facility. The building is 90,000 square feet<br />

with 23-foot high ceiling clearances. In<br />

addition, there are 11 bridge cranes that<br />

move parts and equipment weighing as<br />

much as 30,000 pounds. Multiple fork<br />

trucks access the building from all sides.<br />

“We are definitely equipped to handle<br />

oversized jobs,” said Checker Machine<br />

CEO Steve Lipinski. “Our facility was<br />

designed with flexibility in mind so<br />

that a variety of different needs can be<br />

accommodated.”<br />

In fact, Checker Machine has built<br />

some of the bleachers, railings and<br />

handicap platforms for the St. Louis<br />

Rams, Chicago Bears and Detroit Lions.<br />

“There were bleachers everywhere,”<br />

Lipinski said. “But we didn’t have a<br />

problem with space.”<br />

Some of the most impressive products<br />

built inside Checker Machine, however,<br />

are never even seen by the general public.<br />

They include spiral steam ovens for the<br />

food processing industry. Constructed<br />

entirely out of stainless steel, the spiral<br />

steam ovens contain over 450 feet of belt.<br />

Even more impressive is the amount of<br />

product they are capable of handling.<br />

One type of unit can cook 12,000 pounds<br />

of chicken wings per hour. Other units<br />

can cook 20,000 pounds of meat, fish,<br />

poultry or vegetables per hour.<br />

At 12 feet tall and 30,000 pounds, the<br />

steam ovens are delivered in two pieces<br />

that take up two semi-trailers. They are<br />

designed and built entirely by Checker<br />

Machine.<br />

“There is an incredible amount of skills<br />

and equipment required to produce those<br />

spiral ovens,” Lipinski said. “But we’ve got<br />

what it takes.”<br />

<br />

Checker Machine is home to some<br />

of the largest equipment in the Twin<br />

Cities. One of its Blanchard grinders, for<br />

example, is the largest in the Midwest,<br />

with a 120-inch chuck, a 144-inch swing<br />

and a 48-inch vertical capacity. Checker<br />

Machine also has the largest inventory<br />

of welding equipment and boring mills<br />

in the Twin Cities. Its welding facility<br />

includes the latest welding technology.<br />

“One of the things we try to do for<br />

our customers is minimize our lead times<br />

in case they need immediate access to<br />

our equipment,” Lipinski said. “On an<br />

emergency basis, we can grant them<br />

access in less than 24 hours.”<br />

<br />

PAID SUPPLEMENT