July / August - Minnesota Precision Manufacturing Association

July / August - Minnesota Precision Manufacturing Association

July / August - Minnesota Precision Manufacturing Association

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

OW CRY<br />

rrowcr<br />

providing the<br />

finishing touch<br />

sarrowc<br />

csarrow<br />

icsarro<br />

nicsarr<br />

enicsar<br />

genicsa<br />

ogenics<br />

Starting<br />

Out<br />

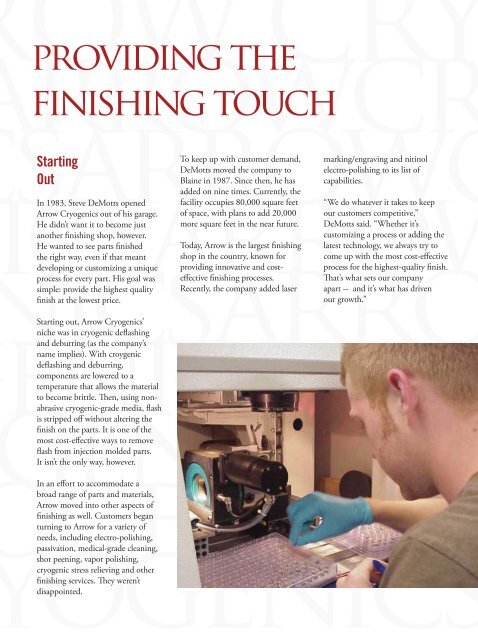

In 1983, Steve DeMotts opened<br />

Arrow Cryogenics out of his garage.<br />

He didn’t want it to become just<br />

another finishing shop, however.<br />

He wanted to see parts finished<br />

the right way, even if that meant<br />

developing or customizing a unique<br />

process for every part. His goal was<br />

simple: provide the highest quality<br />

finish at the lowest price.<br />

Starting out, Arrow Cryogenics’<br />

niche was in cryogenic deflashing<br />

and deburring (as the company’s<br />

name implies). With croygenic<br />

deflashing and deburring,<br />

components are lowered to a<br />

temperature that allows the material<br />

to become brittle. Then, using nonabrasive<br />

cryogenic-grade media, flash<br />

is stripped off without altering the<br />

finish on the parts. It is one of the<br />

most cost-effective ways to remove<br />

flash from injection molded parts.<br />

It isn’t the only way, however.<br />

In an effort to accommodate a<br />

broad range of parts and materials,<br />

Arrow moved into other aspects of<br />

finishing as well. Customers began<br />

turning to Arrow for a variety of<br />

needs, including electro-polishing,<br />

passivation, medical-grade cleaning,<br />

shot peening, vapor polishing,<br />

cryogenic stress relieving and other<br />

finishing services. They weren’t<br />

disappointed.<br />

To keep up with customer demand,<br />

DeMotts moved the company to<br />

Blaine in 1987. Since then, he has<br />

added on nine times. Currently, the<br />

facility occupies 80,000 square feet<br />

of space, with plans to add 20,000<br />

more square feet in the near future.<br />

Today, Arrow is the largest finishing<br />

shop in the country, known for<br />

providing innovative and costeffective<br />

finishing processes.<br />

Recently, the company added laser<br />

marking/engraving and nitinol<br />

electro-polishing to its list of<br />

capabilities.<br />

“We do whatever it takes to keep<br />

our customers competitive,”<br />

DeMotts said. “Whether it’s<br />

customizing a process or adding the<br />

latest technology, we always try to<br />

come up with the most cost-effective<br />

process for the highest-quality finish.<br />

That’s what sets our company<br />

apart -- and it’s what has driven<br />

our growth.”