LT3-00032-2-A - DDKS Industries, hydraulic components distributor

LT3-00032-2-A - DDKS Industries, hydraulic components distributor

LT3-00032-2-A - DDKS Industries, hydraulic components distributor

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

MOUNTING FLANGE,<br />

CAM & CRADLE, BARREL &<br />

AUXILIARY SHAFT ASSEMBLY<br />

(continued)<br />

PARTS LIST FOR FIGURE 3<br />

item description part no. quantity<br />

1 barrel & aux. shaft assembly see fig.4 or 4.1 1<br />

2 override tubes item 24 see fig. 2 2<br />

3 male elbow 473-15041 2<br />

4 tube assembly P24 S13-44469 2<br />

tube assembly P30 S23-12172 2<br />

5 rocker cam & stroking assy. see fig. 2 1<br />

6 dowel pin 324-24028 2<br />

7 mounting flange 033-91137 1<br />

8 o-ring 671-00111 2<br />

9 soc. hd. cap screw 358-16260 2<br />

10 dowel pin 324-22416 1<br />

11 plug 033-57475 2<br />

12 plug 488-35061 3<br />

13 o-ring 691-00904 3<br />

Return the mounting flange to an upright position and tilt the rocker cam to either<br />

extreme attitude on the cradle.<br />

Position the barrel assembly (1) directly over the pistons. Starting with the uppermost<br />

piston, guide them one at time into the barrel bores.<br />

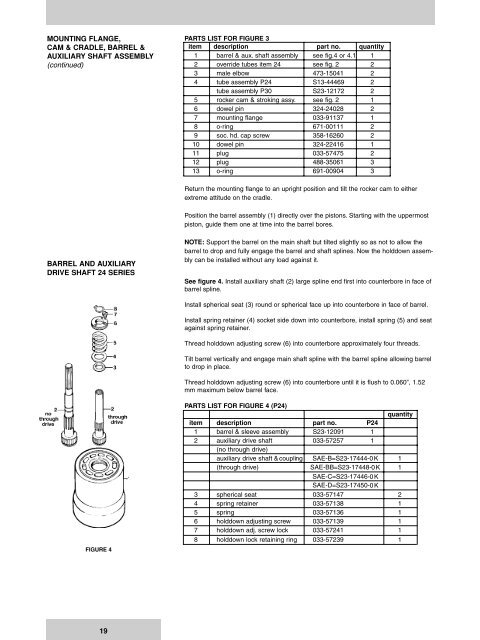

BARREL AND AUXILIARY<br />

DRIVE SHAFT 24 SERIES<br />

NOTE: Support the barrel on the main shaft but tilted slightly so as not to allow the<br />

barrel to drop and fully engage the barrel and shaft splines. Now the holddown assembly<br />

can be installed without any load against it.<br />

See figure 4. Install auxiliary shaft (2) large spline end first into counterbore in face of<br />

barrel spline.<br />

Install spherical seat (3) round or spherical face up into counterbore in face of barrel.<br />

Install spring retainer (4) socket side down into counterbore, install spring (5) and seat<br />

against spring retainer.<br />

Thread holddown adjusting screw (6) into counterbore approximately four threads.<br />

Tilt barrel vertically and engage main shaft spline with the barrel spline allowing barrel<br />

to drop in place.<br />

Thread holddown adjusting screw (6) into counterbore until it is flush to 0.060”, 1.52<br />

mm maximum below barrel face.<br />

FIGURE 4<br />

PARTS LIST FOR FIGURE 4 (P24)<br />

quantity<br />

item description part no. P24<br />

1 barrel & sleeve assembly S23-12091 1<br />

2 auxiliary drive shaft 033-57257 1<br />

(no through drive)<br />

auxiliary drive shaft &coupling SAE-B=S23-17444- 0 K 1<br />

(through drive) SAE-BB=S23-17448- 0 K 1<br />

SAE-C=S23-17446-0 K<br />

SAE-D=S23-17450-0 K<br />

3 spherical seat 033-57147 2<br />

4 spring retainer 033-57138 1<br />

5 spring 033-57136 1<br />

6 holddown adjusting screw 033-57139 1<br />

7 holddown adj. screw lock 033-57241 1<br />

8 holddown lock retaining ring 033-57239 1<br />

19