Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

News2/<strong>2001</strong><br />

Staff and Customer Magazine<br />

<strong>Imperial</strong> companies<br />

display their profile<br />

<strong>Panopa</strong> logistics provides<br />

relief to Volkswagen and<br />

steel suppliers<br />

CTS - a range of services for<br />

container handling<br />

Haniel push boats<br />

constantly on the move<br />

Brouwer Shipping sets<br />

standards for worldwide<br />

coke shipments<br />

In Asia customers can<br />

depend on J.H. Bachmann

At the „Transport Logistic“<br />

in Munich<br />

from 15 to 19 May<br />

<strong>Imperial</strong> Logistics International<br />

GmbH & Co. KG<br />

will present itself to the<br />

public at the above stand<br />

2 � IMPERIAL NEWS<br />

Editorial<br />

Dear Employees, Dear Customers,<br />

in the third issue of our <strong>Imperial</strong> News we would<br />

again like to present examples illustrating how well<br />

<strong>Imperial</strong> Logistics International is equipped for the<br />

future with a broad range of services. Although our<br />

business year does not end until 31st May and the<br />

final figures are therefore not yet available, I can<br />

already report that the volume of business in the<br />

current business year has grown significantly, as<br />

expected. Given shifts between the operating companies,<br />

sales and profit for the corporate group as<br />

a whole will reach the ambitious targets.<br />

The operative companies have consistently<br />

continued to focus on their specific core competencies.<br />

Thanks to the strategic orientation of the companies<br />

of the <strong>Imperial</strong> Logistics International<br />

Group to holistic logistics systems, full service and<br />

worldwide logistics chains on the basis of an international<br />

presence in all parts of the globe, we are<br />

well positioned in the growing logistics market.<br />

Management and staff utilise all their experience<br />

and know-how to remain a competent service<br />

<strong>Imperial</strong> companies display their profile<br />

(model photo). Together<br />

with subsidiaries Brouwer,<br />

Haniel Reederei, J.H. Bachmann,<br />

neska, Schulte &<br />

Bruns and <strong>Panopa</strong> as well<br />

as the two affiliated companies,<br />

<strong>Imperial</strong> Logistics and<br />

partner in whose innovativeness,<br />

performance<br />

and quality our customers<br />

from industry<br />

and trade can trust one<br />

hundred percent.<br />

A key cornerstone for our success is the reinforcement<br />

of the quality offensive within the framework<br />

of Total Quality Management, in which the employees<br />

of all companies play an active role.<br />

Yours,<br />

Gerhard Riemann<br />

Executive Director of <strong>Imperial</strong> Holdings Ltd.,<br />

Edenvale and Chief Executive Officer of <strong>Imperial</strong><br />

Logistics International<br />

<strong>Imperial</strong> Specialised Freight,<br />

South Africa, <strong>Imperial</strong> will<br />

be an exhibitor in Hall B6,<br />

stand 109/208. Under the<br />

heading „<strong>Imperial</strong> Supply<br />

Chain“ the open stand with<br />

a modern design, measur-<br />

ing 210 square metres,<br />

communicates the knowhow<br />

that <strong>Imperial</strong> offers its<br />

customers for material<br />

and information flows<br />

under one roof. �

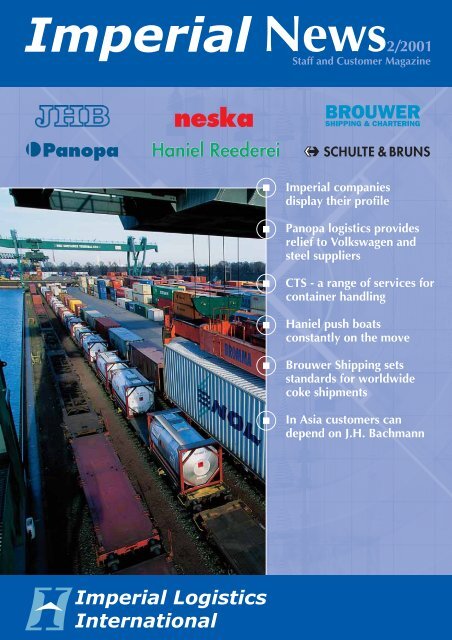

Cover photograph:<br />

CTS terminal 19 in Cologne.<br />

On 27 April <strong>2001</strong> a new<br />

terminal with the 5th crane<br />

bridge was officially opened<br />

at the CTS facility in Köln-<br />

Niehler-Hafen.<br />

2 <strong>Imperial</strong> companies display their profile<br />

19 Works councils establish working<br />

4 <strong>Panopa</strong> logistics provides relief for VW and steel suppliers<br />

7 Strong partner for European shipments<br />

10 dbt supplies the stainless steel industry „just-in-time“<br />

12 CTS – a service centre for container handling<br />

14 Haniel push boats constantly on the move<br />

17 Wijgula Reederei expands with new tankers<br />

17 Takeover of Röhlig branch in Duisburg<br />

18 Brouwer sets new standards for worldwide coke shipments<br />

20 Represented at the hot spots of trade<br />

22 An expert hand for worldwide project business<br />

24 Donations instead of gifts<br />

24 Solidarity in aviation<br />

Table of Contents<br />

<strong>Imperial</strong> Logistics International<br />

Herausgeber: <strong>Imperial</strong> Logistics International GmbH & Co. KG, Duisburg<br />

Kasteelstraße 2 • D-47119 Duisburg<br />

Telefon: +49 (0) 203-8 00 52 30 • Telefax +49(0) 203-80 05-2 84<br />

e-mail: imperial@imperial-international.com<br />

<strong>Panopa</strong><br />

neska<br />

Haniel Reederei<br />

Brouwer Shipping<br />

J. H. Bachmann<br />

IMPERIAL NEWS � 3

Strong, IT-controlled<br />

magnet lifting cranes<br />

handle loading and<br />

unloading of coils at<br />

<strong>Panopa</strong> steel logistics<br />

centre<br />

In the business field of logistic<br />

procurement and<br />

supply for the European<br />

automotive industry <strong>Panopa</strong><br />

has already had experience<br />

with similar projects as this<br />

one in Wolfsburg. Opel,<br />

Daimler Chrysler and also<br />

Volkswagen employ <strong>Panopa</strong><br />

as their logistics provider for<br />

services prior to final production<br />

at other German and<br />

European locations.<br />

Radio-controlled delivery<br />

to the plant<br />

The <strong>Panopa</strong> steel centre<br />

in Wolfsburg meets the highest<br />

requirements, sets standards<br />

and is unique in some<br />

ways: Volkswagen, for example,<br />

has linked its communication<br />

software to the<br />

data technology used in<br />

<strong>Panopa</strong>’s warehouse management<br />

system. The material<br />

flow to the logistics centre<br />

and delivery to the plant are<br />

carried out via rail. Every<br />

day around 60 railway cars<br />

are loaded and unloaded, a<br />

total of approx. 700,000<br />

tonnes of steel sheet coils a<br />

year. This new logistics concept<br />

thus makes a significant<br />

contribution to road traffic<br />

relief, providing for a reduction<br />

of 30,000 truck tours<br />

annually.<br />

4 � IMPERIAL NEWS<br />

Coils and other steel products supplied to the presses right o<br />

<strong>Panopa</strong> logistics provid<br />

for Volkswagen and ste<br />

A big day for <strong>Panopa</strong> and thus for <strong>Imperial</strong> as well: The official opening<br />

of the <strong>Panopa</strong> steel logistics centre in Wolfsburg was on 16 March<br />

<strong>2001</strong>. From here VW is supplied with coils of all kinds from steel plants<br />

Shortly prior to start-up customers, suppliers and the many other guests were impressed by the dim

n the dot<br />

es relief in Wolfsburg<br />

el suppliers<br />

throughout Europe all the way to the body presses and cutting machines<br />

according to need and just-in-time. Everything is transported by<br />

rail. This also ensures considerable relief for the environment.<br />

ensions.The next day the rooms were filled with coils.<br />

To ensure that the highquality<br />

products for VW are<br />

treated gently and arrive at<br />

the plant in flawless condition<br />

with any loss in quality,<br />

<strong>Panopa</strong> has installed an air<br />

conditioning system in the<br />

two large building sections<br />

that provides for constant<br />

humidity (under 55%) and<br />

thus prevents a rust film<br />

from forming on the steel<br />

sheet.<br />

Perfected material logistics<br />

strengthens Germany as<br />

a production location and in<br />

this way secures jobs. The<br />

head of VW Purchasing,<br />

PANOPA<br />

Karl-Peter Peters, got to the<br />

heart of the matter in his<br />

speech at the opening of the<br />

steel logistics centre: „In the<br />

present competitive environment<br />

our automobile future<br />

crucially depends on speed<br />

and flexibility, which are decisive<br />

for a successful partnership<br />

between supplier, logistics<br />

provider and manufacturer.“<br />

This statement<br />

made by Karl-Peter Peters<br />

indicates VW’s high expectations<br />

of the <strong>Panopa</strong> organisation,<br />

which has already<br />

demonstrated its high level<br />

of performance and efficiency<br />

in this field in similar<br />

projects elsewhere.<br />

The fact that Volkswagen<br />

gave <strong>Panopa</strong> Logistik great<br />

responsibility for the entire<br />

production cycle was also<br />

sufficient reason for <strong>Imperial</strong><br />

Holding Executive Chairman<br />

Bill Lynch to hasten<br />

from Johannesburg, South<br />

<strong>Imperial</strong> Holding Executive Chairman Bill Lynch came<br />

from Johannesburg. He acknowledged without reservation<br />

the investment made by <strong>Panopa</strong> for Volkswagen in his<br />

opening speech.<br />

Africa to Wolfsburg. He was<br />

obviously satisfied as he<br />

stepped up to the rostrum.<br />

Lynch thanked VW for the<br />

trust demonstrated by the<br />

placement of this logistics<br />

order and indicated his over-<br />

IMPERIAL NEWS � 5

Around 300 guest were welcomed to the official opening of the <strong>Panopa</strong> steel logistics<br />

centre in Wolfsburg by Gerhard Riemann, CEO of <strong>Imperial</strong> Logistics International.<br />

all satisfaction with the development<br />

of <strong>Panopa</strong> and<br />

the other companies under<br />

the roof of <strong>Imperial</strong> Logistics<br />

International in Germany.<br />

„We made a wise decision<br />

in purchasing these<br />

companies, which belonged<br />

to Thyssen Krupp until a<br />

year and a half ago,“ Bill<br />

Lynch summarised.<br />

This was underlined with<br />

figures by the CEO of <strong>Imperial</strong><br />

Logistics International,<br />

Gerhard Riemann, who is<br />

also a member of the Board<br />

of Management of <strong>Imperial</strong><br />

Holdings in South Africa: at<br />

the end of the business year<br />

<strong>Panopa</strong> Managing Director Heinz-Gerd Sprenger (centre)<br />

talking to members of the Board of Management of DB Cargo<br />

AG, Dr. Dieter Lindenblatt (right) and Dr. Karl-Heinz Jesberg.<br />

6 � IMPERIAL NEWS<br />

on 31st May Gerhard Riemann<br />

expects a doubling of<br />

the sales of the German <strong>Imperial</strong><br />

organisation to 1.5<br />

thousand million DM as<br />

compared to the previous<br />

business year. A nine-figure<br />

sum has been invested in the<br />

current business year alone.<br />

Among other things, in further<br />

distribution centres for<br />

the automotive industry and<br />

related sectors. The number<br />

of employees, which has<br />

risen to around 3000 in the<br />

meantime, is also an indication<br />

of the dynamics at work<br />

in the corporate group. Particularly<br />

at <strong>Panopa</strong>, all ef-<br />

forts are being made to remain<br />

an indispensable future<br />

logistics partner for the automotive<br />

and steel industries.<br />

<strong>Panopa</strong> General Director<br />

Heinz-Gerd Sprenger had<br />

the task of welcoming the<br />

over 300 guests who came to<br />

the opening and who had all<br />

contributed to the rapid implementation<br />

of this project<br />

in their own way. They included<br />

government president<br />

Dr. Axel Saipa from Braunschweig,<br />

representatives of<br />

the City Council and administration<br />

of the city of Wolfsburg<br />

as well as Dr. Dieter<br />

Lindenblatt, member of the<br />

Board of Management and<br />

representative of DB Cargo<br />

AG, in addition to other persons<br />

and those already mentioned<br />

above.<br />

Heinz-Gerd Sprenger<br />

found the short time required<br />

for implementation extremely<br />

remarkable: it took all of<br />

six months from the 1st cut<br />

of the spade to operational<br />

acceptance of the two 220metre-long<br />

and 38-metrewide<br />

halls with all their technical<br />

equipment, such as the<br />

four powerful magnet lifting<br />

cranes. In this period 1,224<br />

metres of track and seven<br />

points were laid within the<br />

facility as well, in addition to<br />

the siding tracks connected to<br />

the DB (German Railway)<br />

and VW rail network.<br />

Sprenger emphasised<br />

again: supply and disposal<br />

for the steel logistics centre<br />

will be carried out exclusively<br />

via rail transport. This<br />

meant, he added, the most<br />

environmentally sound and,<br />

in this case, the most competitive<br />

means of transport<br />

had been selected, making<br />

the undertaking unique in<br />

Europe. Everything had to<br />

be done meticulously, he<br />

stated, since the steel freight<br />

trains have to cross the highly<br />

frequented ICE section of<br />

the German Railway between<br />

Hannover and Berlin<br />

several times a day.<br />

35 trained staff members<br />

have been managing the<br />

steel centre since 19 March.<br />

Three from the Board of the parent company, <strong>Imperial</strong><br />

Holdings Ltd.: Carol Scott, Executive Chairman Bill Lynch<br />

(right) and Gerhard Riemann.

Besides all the new conventional<br />

technology, their efforts<br />

are aided by the use of<br />

state-of-the-art IT systems<br />

for material and warehousing<br />

control.<br />

Each coil, each sheet bar<br />

that enters <strong>Panopa</strong>’s steel<br />

centre in Wolfsburg is given<br />

a bar code. This enables<br />

clear immediate identification<br />

by the staff. „In this way<br />

we always know exactly<br />

where which coil made of<br />

what material is stored for<br />

VW production and thanks<br />

to communicative networking<br />

with the customer, we<br />

also know when it has to be<br />

delivered to the presses and<br />

cutting machines,“ explains<br />

Heinz-Gerd Sprenger.<br />

VW expects higher service<br />

quality from the outsourcing<br />

of logistics and<br />

order placement with<br />

<strong>Panopa</strong>. For example, an upstream<br />

material check and<br />

more flexibility for the press<br />

equipment departments<br />

since the material is available<br />

for different parts more<br />

quickly with the help of<br />

<strong>Panopa</strong>’s control tools.<br />

While the previous coil<br />

stores on the VW plant<br />

grounds covered average<br />

needs for approximately four<br />

work days, material of varying<br />

dimensions can now be<br />

obtained immediately from<br />

the <strong>Panopa</strong> steel logistics<br />

centre, located eight kilometres<br />

away, for four to five<br />

weeks. This means, according<br />

to all those involved,<br />

steel supply for the VW<br />

press departments has been<br />

fundamentally reorganised<br />

through <strong>Panopa</strong> and has now<br />

also been made more inexpensive.<br />

�<br />

This committed <strong>Panopa</strong> team ensured that the official<br />

opening was a successful ceremony and event.<br />

On the afternoon of the opening the first trains rolled into<br />

the <strong>Panopa</strong> facility in Wolfsburg for demonstration purposes<br />

with several loaded cars equipped with sliding sides.<br />

PANOPA<br />

Truck freight transport<br />

Strong partner or<br />

European shipments<br />

„The year 2000 was good and the new year<br />

will be even better,“ emphasises Wolfgang<br />

Müller, responsible for truck freight transport<br />

at <strong>Panopa</strong> Logistik GmbH & Co. KG.<br />

His optimism is based on a constantly<br />

expanding clientele.<br />

<strong>Panopa</strong>’s Central Operations<br />

Planning in Duisburg<br />

alone moves an average<br />

of 29,000 tonnes of<br />

goods a month as cargo,<br />

partial loads and general<br />

cargo. In the truck freight<br />

transport department at<br />

<strong>Panopa</strong> the total monthly<br />

volume is around 170,000<br />

tonnes.<br />

„At present the international<br />

freight business is expanding<br />

very substantially<br />

for us. The expansion to<br />

‘new markets’ is the result<br />

of an acquisition offensive<br />

that has brought about many<br />

new customer contacts and<br />

orders,“ reports Müller.<br />

The right trucks always<br />

at the right place<br />

Müller’s staff is naturally<br />

proud of its skilful and expert<br />

handling of the cargo<br />

entrusted to it. „We are tops<br />

in that department,“ feels<br />

Ulf Wiechmann, too, the responsible<br />

department manager<br />

for <strong>Panopa</strong>’s entire<br />

transport organisation. „Our<br />

know-how covers the whole<br />

freight transport spectrum.<br />

Our customers profit from<br />

that.“<br />

Steel coils with piece<br />

weights of up to 36 tonnes,<br />

long material measuring up<br />

to 24 metres, large-volume<br />

and very heavy goods are no<br />

problem for <strong>Panopa</strong>’s truck<br />

freight transport staff. „We<br />

transport whatever our customers<br />

wish and take care of<br />

all organisational work for<br />

them,“ emphasises Ulf<br />

Wiechmann. „To do this, we<br />

work on a partnership basis<br />

with around 250 truck carriers<br />

and additionally employ<br />

25 subcontractors in Duisburg<br />

in continuous operation,“<br />

adds Wolfgang<br />

Müller.<br />

With these partners<br />

<strong>Panopa</strong> can always provide<br />

its customers with the ap-<br />

Department Manager Wolfgang<br />

Müller: „The penetration<br />

of new markets has<br />

given an additional boost.“<br />

propriate vehicles. Trained<br />

drivers, cargo safety and the<br />

necessary approvals are a<br />

matter of course.<br />

Reliability, punctuality<br />

and on-schedule delivery<br />

are top priority for all<br />

IMPERIAL NEWS � 7

Routine for <strong>Panopa</strong>’s freight department: the right vehicles always transport steel<br />

products of all kinds to the production and storage facilities of the customers.<br />

<strong>Panopa</strong> employees. „This is<br />

the only way we can secure<br />

customer loyalty. To achieve<br />

this, our companies are<br />

regularly evaluated on the<br />

basis of selected criteria.<br />

This system has proven<br />

effective,“ reports Müller.<br />

Müller describes the cooperation<br />

within <strong>Panopa</strong>’s<br />

8 � IMPERIAL NEWS<br />

network of branches as<br />

good. In Germany alone the<br />

company is represented by<br />

20 branch offices. This<br />

makes it possible to set up<br />

truck routes in cooperation<br />

with colleagues at other locations<br />

such that empty runs<br />

are extensively avoided.<br />

„This is a very important as-<br />

pect with regard to pricing<br />

with the truck carriers,“<br />

notes Wiechmann.<br />

The enormous rise in<br />

costs recently (so-called<br />

eco-tax in Germany, diesel<br />

price, wage costs) has called<br />

economic efficiency into<br />

question for many companies.<br />

The consequence has<br />

been transport price increases<br />

that were able to be<br />

passed on to the customers<br />

in most cases, however.<br />

Provider for industrial relocations<br />

Transport is the basis for<br />

all freight business at<br />

<strong>Panopa</strong>, but it is by no<br />

means all that it has to offer<br />

in the way of services. The<br />

organisation of entire chains<br />

of transport as well as normal<br />

individual shipments<br />

are also carried out for the<br />

clients. Wolfgang Müller<br />

and his staff have geared<br />

their operations to this and<br />

gone a step further: „We<br />

also have the capacity and<br />

manpower to handle complete<br />

industrial relocations.“<br />

Meticulous planning is followed<br />

by dismantling, packing,<br />

loading, transport, unloading<br />

and reinstallation.<br />

„We last performed such an<br />

operation for a renowned<br />

manufacturer of automobile<br />

lock systems,“ reports<br />

Müller.<br />

Another brand-new project,<br />

which <strong>Panopa</strong> is carrying<br />

out on behalf of a large<br />

automobile producer, involves<br />

loading, transport<br />

and unloading of a complete<br />

car body production facility<br />

from Wolfsburg to the future<br />

production location in Brussels.<br />

„The successful completion<br />

of this and other orders<br />

strengthens our self-confidence<br />

and our optimism for<br />

the future,“ explains Wolfgang<br />

Müller. �<br />

They advise customers and control a large number of<br />

Marta Birken Uwe Bobsien Ralf Botzek<br />

Jan Burhans<br />

Carmen Buß

PANOPA<br />

Extremely bulky shipments as well as cargo exceeding the dimensions and permissible total weight are not rare for<br />

<strong>Panopa</strong>’s truck freight department.The company is often called for plant transport business.The challenges are mastered<br />

by <strong>Panopa</strong> on the basis of its great experience and skill.<br />

<strong>Panopa</strong>’s road shipments<br />

Thorsten Domke Andreas Müller Jürgen Schelling Steffen Schulz<br />

Michael Zumpro<br />

IMPERIAL NEWS � 9

Additional benefits for stainless steel producers<br />

dbt supplies the stainless steel<br />

industry with additives „just-in-time“<br />

neska’s diverse business fields make a significant contribution to the<br />

capability of <strong>Imperial</strong> companies to offer their customers a great<br />

deal of additional logistic value added beyond traditional freight<br />

forwarding services. For special and stainless steel producers, for<br />

example.<br />

Without stainless steel<br />

our everyday life<br />

would be lacking in<br />

many respects. Whether it be<br />

cutlery, pots, the washing<br />

machine drum, dishwasher<br />

or thermos bottle: increasing<br />

use is made of stainless and<br />

resistant material in the<br />

manufacture of various uten-<br />

10 � IMPERIAL NEWS<br />

sils and consumer articles.<br />

For the production of stainless<br />

steel industry requires<br />

iron alloys, such as ferrosilicon,<br />

ferrochromium, ferromanganese<br />

and silicide, etc.<br />

These additives are procured<br />

from all over the world. „Primarily<br />

Scandinavia, South<br />

Africa and Kazhachstan pro-<br />

duce the alloys in large<br />

quantities. But also Brazil,<br />

Venezuela, India and Indonesia<br />

are among the suppliers,“<br />

says Mario Battistiol,<br />

Managing Director of dbt<br />

Duisburger Bulk Terminal<br />

GmbH, of which neska owns<br />

the majority share.<br />

Jointly with dbt sub-<br />

Wheel loaders and compact loaders ensure rapid movement of ferroalloys in dbt’s<br />

Duisburg sheds.<br />

sidiary luva GmbH (luva<br />

stands for storage and packaging)<br />

as well as the recently<br />

acquired cargo handling<br />

company, Keutmann & Hennemann<br />

in Krefeld Harbour,<br />

the company offers a wide<br />

variety of ways of storing<br />

and handling sensitive alloys<br />

and minerals in 19 warehouses<br />

on a basic area of<br />

around 90,000 square metres.<br />

„We have a total of<br />

60,000 square metres of covered<br />

area at our disposal,“<br />

explains Mario Battistiol.<br />

Altogether about 800,000<br />

tonnes of ferroalloys are<br />

handled for the stainless<br />

steel industry, processed according<br />

to customer demands<br />

and delivered to the<br />

plants just-in-time.<br />

On the grounds at the<br />

outer harbour alone dbt has<br />

13 sheds. Some of them are<br />

equipped with sliding roofs<br />

so the bulk goods can be unloaded<br />

from the vessels directly<br />

into the shed without<br />

going the roundabout way<br />

via wheel loader. The entire<br />

quay length at the outer harbour<br />

is around 1.1 kilometres<br />

long and provides space<br />

for up to four motor coasters.<br />

Extensive know-how<br />

Three cranes with capacities<br />

of between ten and 12.5<br />

tonnes ensure rapid cargo<br />

handling from inland waterway<br />

or coastal vessels to the<br />

sheds or directly onto trucks.<br />

At the new dbt branch in<br />

Krefeld cargo is transhipped<br />

directly from ship to truck<br />

and then taken as quickly as<br />

possible to the plants.<br />

The business of handling<br />

weather-sensitive bulk goods

not only requires extensive<br />

storage and handling space,<br />

but above all considerable<br />

know-how. „Experience is<br />

an important factor in our<br />

business,“ says Battistiol. As<br />

a professional forwarding<br />

agent, he has a lot of it. Battistiol<br />

has been working with<br />

alloys for nearly three<br />

decades and can determine<br />

the origin of the material and<br />

the areas of industrial use on<br />

the basis of its grain size and<br />

colour alone. More than 50<br />

different additives as well as<br />

a number of minerals make<br />

up dbt’s main business.<br />

Around 100 different grain<br />

sizes are constantly stored in<br />

dbt’s facilities.<br />

Storage is carried out in<br />

lots. For this reason the<br />

sheds are divided into compartments.<br />

The compartment<br />

sizes are variable. „We can<br />

store lots of 100 tonnes as<br />

well as 4,000-tonne lots separately,“<br />

adds Battistiol. He<br />

specifies the daily cargo<br />

handling capacity from vessel<br />

to store or truck as approximately<br />

5,000 tonnes.<br />

dbt can store a total of<br />

around 130,000 tonnes in all<br />

its sheds. This makes the<br />

company, in its own view,<br />

number one in Europe in this<br />

market segment.<br />

Handling and processing<br />

of alloys require care and<br />

know-how as well as special<br />

equipment. Thus, dbt has<br />

crushing, grinding, screening<br />

and sorting facilities and<br />

can also dry the materials if<br />

necessary and requested. As<br />

a rule, the additives are delivered<br />

free to the industrial<br />

customers. Transport from<br />

the store in the outer harbour<br />

to the production plant<br />

therefore also falls within<br />

the scope of responsibility of<br />

Duisburg Bulk Terminal<br />

GmbH, which maintains a<br />

substantial truck fleet.<br />

While primarily motor<br />

coasters deliver the materials<br />

from Scandinavia directly to<br />

the dbt quay, alloys and minerals<br />

from overseas are<br />

transported to Europe via the<br />

ARA ports (Antwerp/Rotterdam/Amsterdam).<br />

There the<br />

bulk goods are taken over by<br />

inland waterway vessels.<br />

Kazhachstan, in turn, is<br />

linked to ports in the Baltic<br />

states via rail. From there the<br />

alloys are brought to Duisburg<br />

Bulk Terminal GmbH<br />

at the outer harbour in Duisburg<br />

via Rotterdam.<br />

Speciality is material<br />

treatment<br />

Technically luva<br />

Lagerungs- und Verpackungs-GmbH,<br />

also located in<br />

Duisburg, is even better<br />

geared to special customer<br />

demands. Here again ferroalloys<br />

and minerals are handled<br />

and stored in close cooperation<br />

with dbt. Complementing<br />

dbt’s facilities, it<br />

provides another 40,000<br />

square metres of space.<br />

However, luva’s speciality is<br />

material treatment.<br />

With its extensive technical<br />

equipment luva can<br />

crush, screen, dry and pack<br />

the extremely difficult-toprocess<br />

materials (such as<br />

ferrochromium) to diameters<br />

down to 0.1 millimetre. By<br />

means of, in some cases,<br />

fully automatic and computer-controlled<br />

processes<br />

using conveyor belts, the<br />

material is crushed, screened<br />

and packed in big bags con-<br />

taining up to 1.5 tonnes or in<br />

paper sacks for 10 to 15<br />

kilos. Open customs warehouses<br />

round off the range<br />

of services offered to customers<br />

by luva as well as<br />

dbt.<br />

The most important customers<br />

for dbt are the Krupp<br />

Thyssen stainless steel<br />

plants in Bochum, Krefeld<br />

neska<br />

dbt Managing Director Mario Battistiol: „We ensure a<br />

continuous supply of ferroalloys and other products to<br />

stainless steel producers.“<br />

and Siegen. „Around 60 percent<br />

of the materials go to<br />

these plants,“ says neska<br />

Managing Director Heinz<br />

Bartels. The remaining 40<br />

percent are exported in part<br />

and supplied to other plants.<br />

The relations between dbt<br />

and the Krupp Thyssen<br />

stainless steel production<br />

plants have been embedded<br />

At this approximately one kilometer long quay in the outer harbour Duisburg Bulk Terminal<br />

GmbH (dbt) provides sufficient space for several inland waterway and coastal vessels.<br />

IMPERIAL NEWS � 11

on an even firmer foundation<br />

in the meantime. „We<br />

have concluded a long-term<br />

contract for work and services<br />

that lays down the<br />

specifications for prompt<br />

supply of all three plants<br />

with the additives required<br />

in each case,“ explains Bartels.<br />

Expansion beyond<br />

national borders<br />

dbt is responsible for<br />

prompt delivery of the desired<br />

material to the production<br />

facilities and also provides<br />

for sampling. „In this<br />

way we relieve the Krupp<br />

Thyssen Nirosta (KTN) Purchasing<br />

Division of a major<br />

burden,“ states Battistiol.<br />

Now this division of the<br />

stainless steel producer no<br />

longer has to worry about<br />

operations planning for the<br />

additives, but informs dbt at<br />

short notice. „We then ensure<br />

continuous supply of<br />

ferroalloys and other products<br />

to the production<br />

plants,“ emphasises dbt<br />

Managing Director Mario<br />

Battistiol. And all of this<br />

within a few hours. For very<br />

urgent cases dbt has even<br />

provided the KTN alloy specialists<br />

with mobile phones.<br />

„In this way we ensure constant<br />

accessibility.“<br />

In the medium term dbt<br />

wants to position itself even<br />

better on the market. „We<br />

are convinced that we can<br />

master the increasing demands<br />

of the future,“ states<br />

Battistiol. For example, the<br />

company, which is certified<br />

in accordance with DIN EN<br />

ISO 9002, is already giving<br />

intensive thought to expansion<br />

of its logistics services<br />

to the international market.<br />

„In the medium term we<br />

plan on moving across borders,“<br />

adds neska Managing<br />

Director Heinz Bartels. �<br />

12 � IMPERIAL NEWS<br />

A high level of cargo handling productivity is<br />

attained under these two gantry cranes at the<br />

CTS terminal in the Köln-Niehl Harbour.<br />

Serving industry along the Rhine<br />

CTS - a service centre for<br />

container handling<br />

It is by no means simply local patriotism when Hans-Peter Wieland<br />

claims that his company, CTS, has just the right location here in<br />

Köln-Niehl Harbour since there are a large number of enterprises<br />

that send and receive containers and are geared to import and<br />

export in this city and the surrounding region.<br />

The development of CTS<br />

(Container-Terminal<br />

GmbH Rhein-See-<br />

Land-Service), in which<br />

neska holds the requisite<br />

majority of the share capital,<br />

confirms this assessment by<br />

Managing Director Hans-<br />

Peter Wieland, who has been<br />

with the company since its<br />

establishment at the end of<br />

1983. It has constantly been<br />

following an upward course.<br />

The favourable location in<br />

an urban agglomerate and<br />

industrial centre on the<br />

Rhine accounts for this. Our<br />

trimodal approach, i.e. the<br />

operative linking of truck,<br />

train and ship at the cargo<br />

handling terminal, the performance<br />

of the CTS staff in<br />

the commercial and industrial<br />

sector and the technical<br />

equipment, offers customers<br />

an optimal transport platform.<br />

Five gantry cranes and<br />

eight reach stackers are now<br />

in operation around the<br />

clock on the grounds at the<br />

stacking quay that measure<br />

100,000 square metres.<br />

There is a breather only between<br />

9 pm on Saturday and<br />

10 pm on Sunday.<br />

CTS is a provider for<br />

shipping and freight forwarding<br />

companies with international<br />

operations. These<br />

are the customers whom we<br />

offer services that no one<br />

else at this location performs.<br />

Wieland addresses in<br />

particular the trimodal approach<br />

here: several daily arrivals<br />

and departures of inland<br />

waterway vessels operating<br />

between Cologne and<br />

the seaports of Rotterdam,<br />

Antwerp and Zeebrügge;<br />

container train connections<br />

(Albatros) with Hamburg<br />

and Bremerhaven as well as<br />

the western ports and, of

course, the indispensable deployment<br />

of trucks for short<br />

and long-distance shipments.<br />

We link these carriers<br />

and providers and take care<br />

of cargo handling and temporary<br />

storage. And that’s<br />

not all: handling container<br />

cargo involves additional<br />

tasks related to customs and<br />

safety and not every container<br />

goes through the terminal<br />

FCL, i.e. full and closed, but<br />

also LCL (less than container<br />

load). Outgoing containerisation<br />

is carried out<br />

here on behalf of the customers<br />

- this includes stuffing<br />

general cargo in the CTS<br />

terminal buildings. Conversely,<br />

incoming containers<br />

are opened and unloaded<br />

(stripped ) and individual<br />

lots are delivered to the recipients<br />

after freight for-<br />

warding processing. This<br />

business is increasing and<br />

we gear ourselves to this development<br />

through investments.<br />

Here again CTS does not<br />

see itself as a freight forwarder,<br />

but as a neutral<br />

provider whose services can<br />

be made use of by everyone<br />

in the sector. „The facilities<br />

we have at our disposal<br />

make us a valuable partner<br />

and we try to live up to this<br />

role every day,“ assures co-<br />

Managing Director Karl-<br />

Heinz Schoon.<br />

Wieland assesses the present<br />

and future positively.<br />

The sectors oriented to foreign<br />

trade that are primarily<br />

represented in the Cologne<br />

region, i.e. motor vehicle<br />

production, parts manufacturing,<br />

suppliers and the<br />

neska<br />

The CTS terminal in Köln-Diehl is served according to<br />

schedule by container trains of various companies.<br />

chemical industry, as well as<br />

prospering small and medium-sized<br />

enterprises and the<br />

importing retail and wholesale<br />

trade generate a rising<br />

cargo volume that is stowed<br />

in containers and finds its<br />

way to the buyers via CTS<br />

facilities.<br />

Everything is not a surefire<br />

success, of course.<br />

Wieland and his sales team<br />

are untiring in their efforts<br />

at making the CTS services<br />

known to shipping and<br />

freight forwarding companies.<br />

In many places local<br />

presence is shown so as to<br />

be able to meet customer demands<br />

quickly and consistently.<br />

The endeavours have<br />

been worthwhile: from 1999<br />

to 2000 container handling<br />

movements rose by 12 percent<br />

to 180,000. In the cur-<br />

rent year the 200,000 mark<br />

can be reached. The first<br />

weeks started off well.<br />

For a terminal in an inland<br />

port these are impressive<br />

figures that draw the attention<br />

of all providers of<br />

transport services, such as<br />

truckers, DB Cargo subsidiary<br />

Transfracht and inland<br />

waterway shipping<br />

companies, and thus lead to<br />

a high density of service.<br />

For example, several seaport-based<br />

night operations<br />

by rail, frequent inland waterway<br />

vessel runs and<br />

bustling freight forwarding<br />

Several CTS reach stackers ensure flexibility in the<br />

handling of containers and semitrailers.<br />

traffic by truck. „All of this<br />

is concentrated at CTS and<br />

spurs me and my staff to<br />

continue to expand business,“<br />

reaffirms Hans-Peter<br />

Wieland. �<br />

IMPERIAL NEWS � 13

A reliable partner of the steel industry<br />

Haniel push boats con<br />

In action around the clock and 365 days a<br />

year. Haniel push boats have been operating<br />

on the Rhine for nearly four decades.<br />

Primarily between the ports near Duisburg<br />

and Europoort Rotterdam.<br />

Schwelgern is one of two<br />

main receiving ports<br />

(the other is Walsum-<br />

Süd) belonging to Thyssen<br />

Krupp Stahl AG in Duisburg<br />

on the Lower Rhine that is<br />

called at by around 7,000<br />

push barges and inland waterway<br />

vessels every year.<br />

While Walsum-Süd is<br />

predominantly used for the<br />

transshipment of finished<br />

and semi-finished products,<br />

bulk goods, such as iron ore,<br />

coal, coke, slag and slag<br />

sand, are handled in Schwelgern,<br />

the larger of the two<br />

ports. Three quarter of the<br />

60,000 tonnes handled on<br />

average every day are accounted<br />

for by iron ore<br />

alone.<br />

The crews on the six<br />

Haniel multiple barge convoys<br />

perform a full-time job<br />

in alternating six-hour shifts<br />

for two weeks in turn. This<br />

form of continuous working<br />

hours with subsequent time<br />

off in lieu is called a continue<br />

system, explains Heinz<br />

Schmitz, one of the captains<br />

of „Franz Haniel 15“.<br />

Change on the fly<br />

This time the change of<br />

crew takes place near the<br />

small Dutch town of Rhoon,<br />

only a few kilometres away<br />

from Rotterdam Europoort.<br />

The multiple barge convoy,<br />

altogether 188 metres long<br />

and thus an impressive<br />

sight, maintains course, albeit<br />

slowly, along the edge<br />

of the river. In a dinghy the<br />

first members of the old<br />

crew are taken ashore and<br />

14 � IMPERIAL NEWS<br />

the new crew is brought on<br />

board. On the fly Heinz<br />

Schmitz takes over at the<br />

helm in the wheelhouse and<br />

resumes the voyage towards<br />

Duisburg.<br />

No stops<br />

An observer on board becomes<br />

aware of two things<br />

at this moment: there are no<br />

stops; and speed becomes a<br />

matter of perspective. Upstream<br />

the vessels require<br />

double the time needed to<br />

go downstream. Around 22<br />

hours and about 240 kilometres<br />

lie ahead of the crew before<br />

they reach the port of<br />

Schwelgern.<br />

There are a total of eight<br />

cabins on board, plus a guest<br />

cabin and several wash<br />

rooms. The mess is adjacent<br />

to the spacious galley.<br />

Everything is set up very<br />

practically. One can see that<br />

this is a working area. Cosiness<br />

can only be found within<br />

one’s own four walls. An<br />

aquarium with ornamental<br />

fish alone is enough to create<br />

the impression of a private<br />

sphere.<br />

The crew members eat or<br />

spend their free time in the<br />

mess. A stereo system and a<br />

television with video<br />

recorder help to pass the<br />

time. As a rule, however,<br />

they try to sleep. But with a<br />

six-hour rhythm this is possible<br />

only to a limited extent.<br />

Then there is the constant,<br />

though damped, noise<br />

level of the rumbling engines<br />

in the engine room.<br />

„The first day is always the<br />

Haniel multiple barge convoys predominantly carry iron ore and imported c<br />

worst.“ Everyone agrees<br />

with that. After the twoweek<br />

rest period the body<br />

has to adapt to the new con-<br />

ditions again. Three diesel<br />

engines with a total 4,800<br />

hp generate the power that<br />

drives the steel colossus. Of

HANIEL<br />

tantly on the move<br />

oal for the steel mill industry as they move between Rotterdam and the works ports along the Lower Rhine.<br />

that, the two sideboard engines<br />

each generate a power<br />

of 1,800 hp: in the ideal case<br />

the four barges contain near-<br />

ly 12,000 tonnes of bulk<br />

material. Furthermore,<br />

„Franz Haniel 15“ can also<br />

connect two additional<br />

barges. Then the convoy<br />

would have a cargo volume<br />

of 16,000 tonnes and a<br />

length of 265 metres.<br />

The course is held by<br />

means of a automatic pilot<br />

This time the barges have<br />

loaded three different types<br />

of ore. They orginate from<br />

South Africa and Africa.<br />

Sometimes they even come<br />

from Australia. The largest<br />

ore supplier is Brazil, where<br />

more than half of the Duisburg<br />

cargo volume originates.<br />

Just like the imported<br />

coal, the ore is transported<br />

by gigantic seagoing vessels<br />

to Rotterdam, where German<br />

steel corporations have<br />

enormous open storage facilities<br />

from which they request<br />

the various qualities<br />

needed.<br />

A small, hydraulically<br />

aided control lever is sufficient<br />

to move the over twometre-high<br />

rudder blades at<br />

the stern of the vessel. The<br />

specified course is maintained<br />

by means of an automatic<br />

pilot, even over long<br />

stretches. And besides the<br />

two radar screens, there are<br />

a large number of instrument<br />

displays that convey<br />

more the impression of an<br />

aircraft cockpit.<br />

The speeds of the individual<br />

engines and their current<br />

fuel consumption are<br />

displayed on a PC screen.<br />

Consumption plays a major<br />

role, especially in terms of<br />

economic efficiency. Even<br />

slight changes in engine<br />

power lead to significant<br />

fluctuations in fuel consumption.<br />

Absolutely fantastic<br />

consumption figures<br />

At an average upstream<br />

speed of 10 kilometres an<br />

hour the vessel requires less<br />

than a litre of diesel to move<br />

a tonne of cargo a hundred<br />

kilometres. Neither road<br />

IMPERIAL NEWS � 15

carriers nor rail transport<br />

can compete with this level<br />

of consumption.<br />

Who actually cooks on<br />

board? „Whoever has time<br />

and can cook,“ explains<br />

helmsman Maik Mayer as<br />

he washes the lunch dishes.<br />

„There used to be a cook<br />

here,“ he adds. Presumably<br />

no one can afford such luxury<br />

any more today in view<br />

of the prices on the inland<br />

waterway shipping market.<br />

Thus, the crew presents itself<br />

to viewers as a smoothly<br />

functioning group of men<br />

sharing a household.<br />

While cows graze on the<br />

banks of the Rhine, bustling<br />

traffic prevails on the river.<br />

After all, „Franz Haniel 15“<br />

operates on the most frequented<br />

waterway in the<br />

world. Motor vessels con-<br />

16 � IMPERIAL NEWS<br />

stantly pass by in both directions.<br />

In spite of their actual<br />

length, when viewed from<br />

above, these vessels appear<br />

like small cars from the<br />

point of view of a truck driver.<br />

Otherwise much is reminiscent<br />

of a highway, only<br />

on water.<br />

„The actual hazards are<br />

not above, but below the<br />

water surface,“ says Captain<br />

Schmitz. „At many places<br />

along the river there are<br />

shallows where the water<br />

ripples on the surface.<br />

Shallows demand<br />

precise navigation<br />

Despite the stipulated<br />

navigation channel, special<br />

care must be taken when<br />

navigating in shallow water.<br />

In certain sections the multiple<br />

barge convoy moves<br />

only half a metre above the<br />

bottom. Then you can see<br />

how the ship churns up the<br />

sand to the water surface.“<br />

Schmitz and the other captains<br />

know this section like<br />

the back of their hand.<br />

The heart of „Franz<br />

Haniel 15“ is the engine<br />

room. The vessel has three<br />

engines, each a 16-cylinder<br />

turbo diesel as large as a<br />

VW van. During the last<br />

servicing the engines were<br />

given a general overhaul.<br />

Broken down into individual<br />

parts, they were examined<br />

thoroughly and all wearing<br />

parts replaced. Now they are<br />

to give the vessel new thrust<br />

for at least another 60,000<br />

operating hours.<br />

Punctually as planned,<br />

„Franz Haniel 15“ arrives at<br />

the port in Schwelgern. Just-<br />

in-time. The harbour basin<br />

extends, straight as a die,<br />

over a length of about one<br />

kilometre. As of here the<br />

harbourmaster in his lofty<br />

control station takes over<br />

command of the cargo.<br />

Brief instructions and boatsmen<br />

and heimsmen loosen<br />

the thick wire ropes that<br />

held the convoy together for<br />

24 hours. The four barges<br />

are cast off. Meanwhile in<br />

the river the empty pushed<br />

barges already await their<br />

downstream voyage to Rotterdam.<br />

●<br />

Three 16-cylinder turbo diesel engines generating a total power of up to 4,800 hp make Haniel multiple barge convoys<br />

powerful enough to be able to push six loaded barges upstream.

Safe transport service for the chemical industry<br />

Wijgula shipping company<br />

expands with new tankers<br />

Haniel Reederei subsidiary Wijgula in the<br />

Dutch city of Druten has put two additional<br />

new inland motor tankers into operation.<br />

This means Wijgula now has 32 tanker<br />

units, including five new additions with<br />

tanks made of stainless steel.<br />

In specialised tanker shipping<br />

Wijgula holds a top<br />

position in western Europe<br />

with its fleet of 32 tankers.<br />

The most recent new vessels<br />

include the tanker „Synthese<br />

4“, which was delivered<br />

by the De Gerlien Van<br />

Tiem B. V. shipyard in<br />

Druten on 20 December,<br />

and TMS „Synthese 10“,<br />

which was built at the Smits<br />

shipyard in Krimpen on the<br />

River Lek and set off on its<br />

maiden voyage on 2nd January.<br />

Both ships have been in<br />

operation from the first day<br />

onward.<br />

„Synthese 4“ is a doublehull<br />

tanker of the ADNR<br />

type „N closed“. It can be<br />

used to transport most liquid<br />

chemicals provided they are<br />

not highly explosive or<br />

highly toxic. The vessel can<br />

be loaded with 1,707 tonnes<br />

of cargo. The predecessor,<br />

„Synthese 3“, has the same<br />

design while the new vessels<br />

„Synthese 6“ and „Synthese<br />

2“, in turn, also have the<br />

same design. The entire<br />

„Synthese“ series has<br />

proven to be very successful<br />

thus far.<br />

„Synthese 4“ has two independent<br />

tank units with<br />

separate loading and discharging<br />

systems. It is primarily<br />

operated between the<br />

ARA ports on the Rhine and<br />

chemical plants along the<br />

river.<br />

TMS „Synthese 10“ is a<br />

motor tanker of the C type<br />

conforming to the ADNR<br />

regulations. C stands for<br />

chemical and means that all<br />

The new tanker „Synthese 10“ is<br />

approved for the transport of all<br />

liquid chemicals.<br />

liquid chemicals approved<br />

for transport on waterways<br />

can be conveyed with this<br />

type of vessel. This also includes<br />

all highly toxic and<br />

highly explosive liquids.<br />

Since this last vessel represents<br />

a new type of ship<br />

for Wijgula, the name „Synthese<br />

10“ was chosen to as<br />

to indicate that it is a new<br />

series. Deployment of this<br />

tanker with a cargo capacity<br />

of 2,001 tonnes, equipped<br />

with tanks and pipe systems<br />

made of stainless steel, supplements<br />

the existing transport<br />

activities of the shipping<br />

company, on the one<br />

hand, while opening up new<br />

potential in the transport<br />

market for hazardous goods,<br />

on the other.<br />

The crew on board has<br />

considerable experience in<br />

chemical shipping, enabling<br />

24-hour operation of this<br />

vessel. The crews are<br />

changed every week according<br />

to the principle: one<br />

week on board, one week<br />

off. �<br />

HANIEL<br />

Haniel<br />

strengthens<br />

its position<br />

Haniel Umschlag und Industrie-Logistik<br />

GmbH<br />

& Co. KG, Duisburg<br />

(HUIL), a 100% subsidiary<br />

of Haniel Reederei Holding<br />

GmbH, took over the business<br />

activities of Röhlig &<br />

Co., Duisburg branch, and<br />

Cargo-Spedition GmbH,<br />

Duisburg, in the ferroalloy<br />

sector as well as part of the<br />

operating facilities, effective<br />

as of 15 November 2000.<br />

The activities assumed<br />

round off the range of cargo<br />

handling, storage, processing<br />

and logistics services offered<br />

by HUIL and represent<br />

a sensible extension of<br />

the industrial logistics division<br />

of Haniel Reederei<br />

Holding.<br />

Continuity in customer<br />

relations and the related orders<br />

is ensured by virtue of<br />

the fact that HUIL has kept<br />

on 15 staff members. This<br />

means that HUIL now employs<br />

a total of over 90 employees.<br />

HUIL now has an area of<br />

140,000 m 2 at its disposal,<br />

including 50,000 m 2 of covered<br />

storage and around<br />

4,400 m 3 of silo capacity.<br />

The company will significantly<br />

expand its market position<br />

in future, supported<br />

by the logistics activities in<br />

the ferroalloy sector. �<br />

IMPERIAL NEWS � 17

Between China and Europe<br />

Brouwer sets new standards<br />

for worldwide coke shipments<br />

As a provider of sea transport services,<br />

Brouwer is constantly building up a good<br />

reputation. The committed shipping business<br />

staff members of the „Brouwer crew“ discover<br />

and develop niche markets, thus provide<br />

benefits to the customers and have corporate<br />

success themselves.<br />

To be on the lookout<br />

worldwide for shipping<br />

opportunities that result<br />

in advantages for everyone.<br />

This is the basic principle<br />

with which Brouwer Shipping<br />

and Chartering GmbH,<br />

a member of the <strong>Imperial</strong><br />

Group, pursues its business<br />

activities at its headquarters<br />

in Hamburg and at other locations<br />

around the globe.<br />

„We can best illustrate this<br />

endeavour on the basis of<br />

examples, such as a number<br />

of coke shipments from Tianjin<br />

region on the Yellow<br />

Sea in the northeastern area<br />

of the People’s Republic of<br />

China to Antwerp and Rotterdam<br />

via the port of Xingang<br />

and then further to the<br />

Lower Rhine,“ explains<br />

Brouwer Managing Director<br />

Holger Ranf.<br />

The German steel industry<br />

obtains part of its raw<br />

materials for the melting of<br />

ore from overseas. This includes<br />

coke from China.<br />

This coke, which is suitable<br />

for blast furnace processing,<br />

is offered at competitive<br />

prices according to the standards<br />

of the world coke<br />

market, but the freight costs<br />

for the long route to the<br />

buyers represent, nevertheless,<br />

a burden that must be<br />

minimized. Recently<br />

Brouwer Shipping has succeeded<br />

several times in reducing<br />

transport costs in<br />

close partnership with<br />

18 � IMPERIAL NEWS<br />

Krupp Energiehandel<br />

(KEH) and the responsible<br />

Chinese government offices.<br />

„We were able to combine<br />

things that were previously<br />

not possible in this<br />

constellation,“ reports Ranf.<br />

For example, it was determined<br />

at an early stage that<br />

after dredging work on its<br />

navigation channel the port<br />

of Xingang can now to accessible<br />

by vessels significantly<br />

larger than the Panmax<br />

category (the maximum<br />

deployable vessel size<br />

for the port up to then), i.e.<br />

ships with a capacity of<br />

75,000 tonnes. This means<br />

ships can be used that are<br />

classified in charter business<br />

as „cape size“ and<br />

carry dry cargo well in excess<br />

of 120,000 tonnes.<br />

Since coke is a lightweight<br />

commodity, only<br />

around 75% of the maximum<br />

carrying capacity is<br />

reached despite full cargo<br />

space utilisation. This, in<br />

turn, results in a lower<br />

draught, making it possible<br />

to take on a full load in Xingang<br />

and also pass through<br />

the Suez Canal by means of<br />

„cape size“ bulk carriers,<br />

which can currently be chartered<br />

at lower freights than<br />

Panmax vessels.<br />

„Although Xingang was<br />

not geared to „cape size“ up<br />

to now, the port employees<br />

managed to fill the ship’s<br />

belly with around 80,000<br />

tonnes of coke within approximately<br />

40 working<br />

hours with their grab crane<br />

facilities in cooperation with<br />

KEH’s Tianjin office, even<br />

during the most important<br />

Chinese holiday, the Chinese<br />

New Year/Spring Festival,“<br />

notes Ranf appreciatively.<br />

All these factors together<br />

- speedy loading, larger vessels,<br />

lower freight rates and<br />

a shorter route through the<br />

161-kilometre Suez Canal<br />

instead of the long stretch<br />

around the Cape of Good<br />

Hope - produce additional<br />

sales for the Chinese coking<br />

plants and competitive marketing<br />

potential for Krupp<br />

Energiehandel. „We at<br />

„Cape size“ vessel sizes were previously unknown to the teams at the crane facilities in<br />

Xingang. Nevertheless, 80,000 tonnes of coke were loaded from the storage site into a<br />

ship’s belly in around forty working hours.

Brouwer Shipping and<br />

Chartering have contributed<br />

to this by linking all these<br />

elements, combined with<br />

outstanding cooperation between<br />

all those involved -<br />

management and staff of<br />

Krupp Energiehandel, its of-<br />

BROUWER SHIPPING<br />

It is cold in northeastern China.The „cape size“ bulk carrier chartered by Brouwer,Aghios Charalambos, was surrounded<br />

by drift ice in the port of Xingang while it took on 80,000 tonnes of coke for Krupp Energiehandel there in February.<br />

fice in Tianjin, the port authorities<br />

and the local authorities,“<br />

points out Holger<br />

Ranf.<br />

„Actually it is a matter of<br />

course for us as a shipper<br />

and charterer of seagoing<br />

vessels,“ adds Ranf. Howev-<br />

er, one has to be extremely<br />

familiar with the markets<br />

and have worldwide contacts<br />

to be able to respond<br />

quickly. The flexibility of<br />

the company is of crucial<br />

importance. In this case<br />

Brouwer was once again the<br />

first company able to optimise<br />

coke business between<br />

market leader Krupp Energiehandel<br />

and the Chinese<br />

suppliers. �<br />

Works councils establish working<br />

Aworking group of the<br />

<strong>Imperial</strong> works<br />

council has been<br />

constituted since March<br />

of this year. The following<br />

<strong>Imperial</strong> subsidiaries are<br />

involved in this working<br />

group: J. H. Bachmann<br />

GmbH, <strong>Panopa</strong> Logistik<br />

GmbH + Co. KG, Haniel<br />

Transport & Schiffahrt<br />

GmbH & Co. KG, Haniel<br />

Schiffahrt GmbH, Haniel<br />

Reederei GmbH, Haniel<br />

Umschlag und Industrie-<br />

Logistik GmbH & Co.<br />

KG, dbt Duisburg Bulk<br />

Terminal GmbH and<br />

neska Schiffahrt und<br />

Speditionskontor GmbH.<br />

At the constituent assembly<br />

of the working group<br />

on 8 March the following<br />

office holders were selected<br />

at the Haniel<br />

Akademie in Duisburg:<br />

Chairman<br />

Hans-Jürgen Friedel<br />

(<strong>Panopa</strong> Logistik GmbH<br />

& Co. KG)<br />

Deputy Chairman<br />

Peter Jürgen Fink (Haniel<br />

Transport & Schiffahrt<br />

GmbH & Co. KG)<br />

Secretary<br />

Daniela Arens (Haniel<br />

Reederei GmbH)<br />

On the basis of the constant<br />

economic and staffrelated<br />

growth of <strong>Imperial</strong><br />

Logistics International,<br />

the works councils, as<br />

representatives of around<br />

1,500 employees in Germany<br />

and 2,500 employees<br />

worldwide, would like<br />

to continue and expand<br />

the continuous cooperation<br />

based on trust over<br />

the past years with the<br />

Board of Management<br />

and the executive staff of<br />

the specific companies.<br />

The establishment of the<br />

working group represents<br />

an initial organisational<br />

step on the part of the<br />

works councils towards a<br />

functioning representation<br />

of interests in our jointly<br />

experienced corporate<br />

culture (Haniel and<br />

Thyssen Krupp), and<br />

builds on the previous<br />

good experience with this<br />

body based on the<br />

Labour-Management Relations<br />

Act, points out<br />

Hans-Jürgen Friedel.<br />

The working group will<br />

not perform the work of<br />

the individual works<br />

council bodies and not be<br />

a „supra-works council“,<br />

but will merely provide<br />

assistance in solving<br />

problems as needed. Furthermore,<br />

it will be a contact<br />

for the individual <strong>Imperial</strong><br />

subsidiaries and<br />

input its substantial experience<br />

in looking for possible<br />

solutions for Groupspecific<br />

concerns and<br />

problems. As a first step,<br />

dates for talks were<br />

arranged with the Board<br />

of Management and the<br />

individual management<br />

staff members for the year<br />

<strong>2001</strong>. �<br />

IMPERIAL NEWS � 19

In Asia customers can depend on J.H.Bachmann<br />

Represented at the<br />

hot spots of trade<br />

The opening of the Chinese<br />

market in the<br />

1970s proved to be decisive<br />

for J. H. Bachmann’s<br />

commitment in the Far East,<br />

with Hong Kong serving as<br />

the gateway from China to<br />

the West. From there J. H.<br />

Bachmann took the first<br />

strategic steps towards further<br />

expansion. To strengthen<br />

its presence in the “Middle<br />

Kingdom”, a branch office<br />

was opened at first in<br />

Guangzhou, Canton, northwest<br />

of Hong Kong. This<br />

was then followed by further<br />

offices in Xiamen on the<br />

Formosa Strait across from<br />

Taiwan as well as in Shanghai<br />

and Beijing. J. H. Bachmann<br />

performed demanding<br />

freight forwarding services<br />

there.<br />

The head office was always<br />

in Hong Kong, ex-<br />

20 � IMPERIAL NEWS<br />

Asia has been a prominent region for the<br />

freight forwarding sector for over 20 years.<br />

This also applies for J. H. Bachmann. The<br />

branch in Hong Kong was established in<br />

1978. This was soon followed by further offices<br />

in the People’s Republic of China and in<br />

other places in the region. Additional investments<br />

are planned.<br />

plains Hans-Jörg Roost,<br />

who has worked for the<br />

Group in Hong Kong since<br />

1985. Hong Kong is one of<br />

the leading financial centres<br />

in the world and is considered<br />

to be the place where a<br />

provider must be present in<br />

order to conduct foreign<br />

trade business between East<br />

and West. Furthermore,<br />

Hong Kong is the largest<br />

container port in the world,<br />

where well over 18 million<br />

TEU are handled every year.<br />

J. H. Bachmann operates<br />

two warehouses in Hong<br />

Kong. One is used for consolidating<br />

air freight shipments,<br />

i.e. combining them<br />

into larger cargo units, and<br />

then flying them to, or<br />

receiving them from, all<br />

points around the globe. The<br />

other warehouse serves as a<br />

logistics and distribution<br />

centre. Ball bearings, computer<br />

parts, perfume and<br />

wine are some of the highquality<br />

products handled by<br />

Bachmann here. A section<br />

of the logistics centre has<br />

been equipped with an air<br />

conditioning system so as to<br />

maintain the quality of the<br />

goods, particularly wine and<br />

perfume.<br />

The Bachmann team in<br />

Xiaman focuses on outgoing<br />

sea freight and organises the<br />

necessary procedures. Xiaman<br />

plays a growing role as<br />

a major trade centre in<br />

South China. Hans-Jörg<br />

Roost is convinced that the<br />

Bachmann branch will certainly<br />

profit from this and<br />

also from the increasing<br />

business due to the recent<br />

development/discussion between<br />

Taiwan and China.<br />

Situated at the mouth of<br />

the Yangtze River on the<br />

east coast of China, Shanghai<br />

is also developing into a<br />

mega-location in every respect.<br />

Here again Bachmann<br />

constantly adapts its opera-<br />

Hans-Jörg Roost, Managing Director of J. H. Bachmann (Hong Kong) Ltd. and at the same time responsible for Asia, at a<br />

morning briefing.

Expansion of the logistic activities of the Bachmann<br />

organisation in Hong Kong is met with a positive response<br />

from customers.The pictures show (left) the second floor<br />

tion to the growing business<br />

volume.<br />

In China’s capital, Beijing,<br />

air freight shipment<br />

from all parts of the country<br />

account for a substantial<br />

volume of the total cargo.<br />

Loading and unloading,<br />

temporary storage and consolidation<br />

have always been<br />

and still are quite complex<br />

at this location.<br />

Growing use is made of<br />

Bachmann’s services for<br />

smooth and rapid cargo handling,<br />

including all customs<br />

information. The Beijing<br />

staff also organises precarriage<br />

and subsequent transport<br />

in northern China on<br />

behalf of its customers.<br />

Business is booming in<br />

Taiwan as well, where particular<br />

emphasis must be<br />

placed on the dramatic<br />

growth in foreign trade with<br />

several South American<br />

countries recently.<br />

Bangkok is, of course,<br />

the heart of the Thai market.<br />

There J. H. Bachmann additionally<br />

assumes coordination<br />

responsibility for shipments<br />

to and from the<br />

neighbouring countries of<br />

Vietnam, Laos, Cambodia<br />

and Myamar. The Bachmann<br />

branch there also has<br />

a high level of competence<br />

in handling project business.<br />

Despite still generally<br />

weak economic growth, the<br />

Bachmann activities in<br />

Bangkok had to be strengthened.<br />

The customs clearance<br />

department is well established,<br />

says Thailand Manager<br />

Rainer David. It has its<br />

own licences and works for a<br />

numerous local and international<br />

customers in Thailand.<br />

Indonesia is also a success<br />

story for Bachmann.<br />

The branch in Djakarta is<br />

now regarded and recognised<br />

as one of the best air<br />

freight forwarding companies<br />

in the country for shipments<br />

to Europe, states Vollrad<br />

Peter Hagen, head of the<br />

Indonesian organisation.<br />

The development of<br />

Bachmann’s branches in<br />

BACHMANN<br />

of a Bachmann warehouse, which can also be accessed by<br />

heavy trucks. On the right is one of several Bachmann<br />

distribution vehicles.<br />

Asia looks good in the near<br />

future in Roost’s estimation.<br />

Now being part of the <strong>Imperial</strong><br />

Group, it is certain that<br />

J. H. Bachmann will continue<br />

to expand.<br />

In his responsibility as<br />

regional manager for Asia,<br />

Hans-Jörg Roost views his<br />

top priority as the consolidation<br />

and further development<br />

of his office’s own<br />

presence in the major countries<br />

of Asia.<br />

Trans-Pacific trade with<br />

North and South America is<br />

regarded as especially capable<br />

of expansion. Initial business<br />

transactions have already<br />

been concluded with new<br />

customers on these routes.<br />

Now branches are also to<br />

be opened in Malaysia and<br />

Taiwan, possibly even with<br />

local partners. Soon it will<br />

be Singapore’s turn as well.<br />

„In the difficult Japanese<br />

market,“ according to<br />

Roost, „we will establish a<br />

joint venture at the proper<br />

time in any case.“ However,<br />

it is also important that the<br />

company’s presence is extended<br />

significantly as<br />

planned in the USA in order<br />

to build up activities in this<br />

region, too. “It is only a<br />

matter of time until the<br />

name of JHB will appear on<br />

the map of many other<br />

countries in Asia“ says<br />

Roost. �<br />

In Hong Kong more than 50 Bachmann staff members ensure smooth operations<br />

planning and documentation of the incoming and outgoing shipments.<br />

IMPERIAL NEWS � 21

Bachmann’s freight forwarding specialists are in overseas at home<br />

An expert hand for worldwid<br />

A worldwide freight forwarding organisation<br />

is necessary, of course, to be able to transport<br />

even the largest pieces from door to<br />

door without any problem. J. H. Bachmann<br />

demonstrates day in and day out that project<br />

Project freight forwarding<br />

of cargo with un-<br />

„<br />

usual dimensions and<br />

weights for manufacturers,<br />

exporters and consignees<br />

can be handled and organ-<br />

22 � IMPERIAL NEWS<br />

ised most professionally<br />

when we as an experienced<br />

freight forwarding company<br />

are involved right from the<br />

planning phase“, states Jörn<br />

Evers, the general manager<br />

Finished! All parts of a tunnel drilling machine made by<br />

Wirth have been stowed in the cargo holds of the MS<br />

“Szymannowski” and are ready for sea transport to<br />

China. Shipment of the 15,000 freight tonnes of cargo was<br />

organised down to the last detail by J. H. Bachmann from<br />

the manufacturer’s plant to the final destination in the<br />

Chinese hinterland.<br />

freight forwarding business of this kind has<br />

nearly become routine. In Germany the<br />

Bachmann offices in Bremen and Hamburg<br />

in particular are the experienced specialists<br />

that hold the reins.<br />

of the Bachmann office in<br />

Hamburg.<br />

The Bachmann team is<br />

well occupied. „We would<br />

be poor freight forwarders if<br />

this were not the case given<br />

the present export boom,”<br />

emphasizes Jürgen Rowold,<br />

who is responsible for ocean<br />

freight at Bachmann in<br />

Hamburg.<br />

„The most exciting business<br />

is export project freight<br />

forwarding when goods are<br />

sold ex works and/or free site<br />

and we organise and manage<br />

all deliveries, the cargo handling<br />

operations all the way<br />

to the destination on behalf<br />

of the shipper or consignee,”<br />

explains Jörn Evers.<br />

A job for pros<br />

The challenges begin<br />

right from initial transport<br />

from the inland plant to the<br />

vessel at the port of loading:<br />

all precarriage of cargo that<br />

exceeds the dimensions and<br />

weights specified in the<br />

road traffic regulations may<br />

only be transported with<br />

special permits and such approval<br />

must be obtained<br />