Spray Nozzles Spray Control Spray Analysis Spray Fabrication

Spray Nozzles Spray Control Spray Analysis Spray Fabrication

Spray Nozzles Spray Control Spray Analysis Spray Fabrication

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Strip Wash-Off/Hot Strip Mill<br />

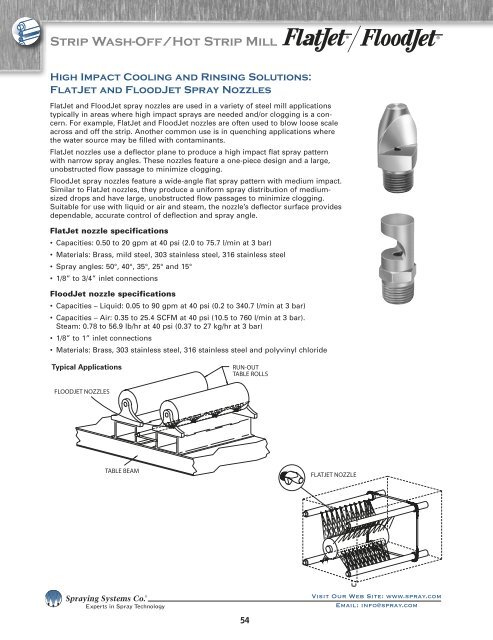

High Impact Cooling and Rinsing Solutions:<br />

FlatJet and FloodJet <strong>Spray</strong> <strong>Nozzles</strong><br />

FlatJet and FloodJet spray nozzles are used in a variety of steel mill applications<br />

typically in areas where high impact sprays are needed and/or clogging is a concern.<br />

For example, FlatJet and FloodJet nozzles are often used to blow loose scale<br />

across and off the strip. Another common use is in quenching applications where<br />

the water source may be filled with contaminants.<br />

FlatJet nozzles use a deflector plane to produce a high impact flat spray pattern<br />

with narrow spray angles. These nozzles feature a one-piece design and a large,<br />

unobstructed flow passage to minimize clogging.<br />

FloodJet spray nozzles feature a wide-angle flat spray pattern with medium impact.<br />

Similar to FlatJet nozzles, they produce a uniform spray distribution of mediumsized<br />

drops and have large, unobstructed flow passages to minimize clogging.<br />

Suitable for use with liquid or air and steam, the nozzle’s deflector surface provides<br />

dependable, accurate control of deflection and spray angle.<br />

FlatJet nozzle specifications<br />

• Capacities: 0.50 to 20 gpm at 40 psi (2.0 to 75.7 l/min at 3 bar)<br />

• Materials: Brass, mild steel, 303 stainless steel, 316 stainless steel<br />

• <strong>Spray</strong> angles: 50°, 40°, 35°, 25° and 15°<br />

• 1/8” to 3/4” inlet connections<br />

FloodJet nozzle specifications<br />

• Capacities – Liquid: 0.05 to 90 gpm at 40 psi (0.2 to 340.7 l/min at 3 bar)<br />

• Capacities – Air: 0.35 to 25.4 SCFM at 40 psi (10.5 to 760 l/min at 3 bar).<br />

Steam: 0.78 to 56.9 lb/hr at 40 psi (0.37 to 27 kg/hr at 3 bar)<br />

• 1/8” to 1” inlet connections<br />

• Materials: Brass, 303 stainless steel, 316 stainless steel and polyvinyl chloride<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

54