Spray Nozzles Spray Control Spray Analysis Spray Fabrication

Spray Nozzles Spray Control Spray Analysis Spray Fabrication

Spray Nozzles Spray Control Spray Analysis Spray Fabrication

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Dust <strong>Control</strong>/Gas Cooling<br />

Effective Dust <strong>Control</strong> and Gas Conditioning<br />

Depends on Drop Size… And We Have the<br />

Systems, <strong>Nozzles</strong> and Data You Need<br />

Whether you’re looking for hydraulic spray nozzles for dust control or gas cooling,<br />

energy-efficient air atomizing nozzles for evaporative cooling or a fully automated<br />

system for gas conditioning, you’ll find we have a wide assortment of<br />

proven solutions.<br />

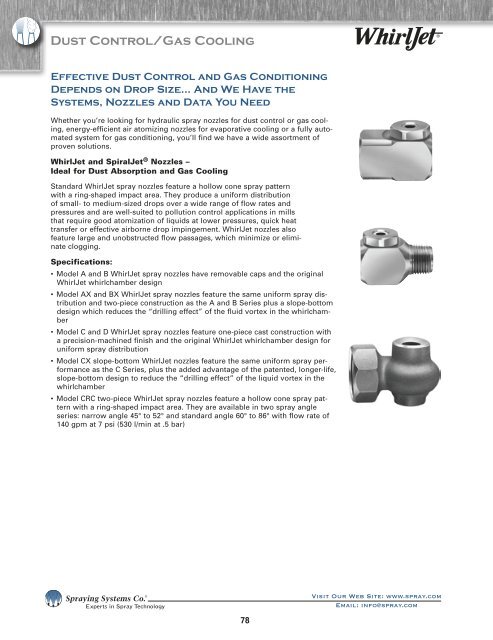

WhirlJet and SpiralJet ® <strong>Nozzles</strong> –<br />

Ideal for Dust Absorption and Gas Cooling<br />

Standard WhirlJet spray nozzles feature a hollow cone spray pattern<br />

with a ring-shaped impact area. They produce a uniform distribution<br />

of small- to medium-sized drops over a wide range of flow rates and<br />

pressures and are well-suited to pollution control applications in mills<br />

that require good atomization of liquids at lower pressures, quick heat<br />

transfer or effective airborne drop impingement. WhirlJet nozzles also<br />

feature large and unobstructed flow passages, which minimize or eliminate<br />

clogging.<br />

Specifications:<br />

• Model A and B WhirlJet spray nozzles have removable caps and the original<br />

WhirlJet whirlchamber design<br />

• Model AX and BX WhirlJet spray nozzles feature the same uniform spray distribution<br />

and two-piece construction as the A and B Series plus a slope-bottom<br />

design which reduces the “drilling effect” of the fluid vortex in the whirlchamber<br />

• Model C and D WhirlJet spray nozzles feature one-piece cast construction with<br />

a precision-machined finish and the original WhirlJet whirlchamber design for<br />

uniform spray distribution<br />

• Model CX slope-bottom WhirlJet nozzles feature the same uniform spray performance<br />

as the C Series, plus the added advantage of the patented, longer-life,<br />

slope-bottom design to reduce the “drilling effect” of the liquid vortex in the<br />

whirlchamber<br />

• Model CRC two-piece WhirlJet spray nozzles feature a hollow cone spray pattern<br />

with a ring-shaped impact area. They are available in two spray angle<br />

series: narrow angle 45° to 52° and standard angle 60° to 86° with flow rate of<br />

140 gpm at 7 psi (530 l/min at .5 bar)<br />

78