Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

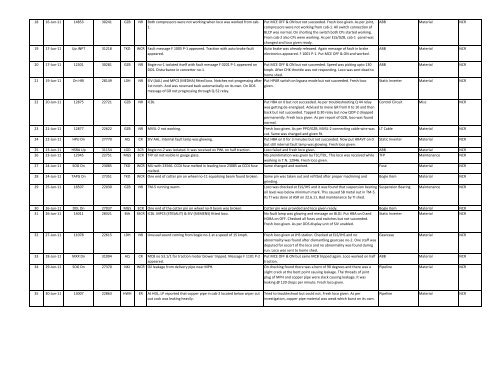

18 16‐Jun‐11 14853 30241 GZB NR Both compressors were not working when loco was worked from cab‐<br />

1.<br />

19 17‐Jun‐11 Up JNPT 31218 TKD WCR Fault message F 1005 P‐1 appeared. Traction with auto brake fault<br />

appeared.<br />

20 17‐Jun‐11 12301 30281 GZB NR Bogie no‐1 isolated itself with fault message F 0201 P‐1 appeared on<br />

DDS. Disturbance in converter no‐1.<br />

21 19‐Jun‐11 Dn HRI 28149 LDH NR SIV (AAL) and MPCS (MEDHA) fitted loco. Notches not progressing after<br />

1st notch. And was reversed back automatically on its own. On DDS<br />

message of GR not progressing through Q‐52 relay.<br />

Put MCE OFF & ON but not succeeded. Fresh loco given. As per joint,<br />

compressors were not working from cab‐1. All switch connection of<br />

BLCP was normal. On shorting the switch both CPs started working.<br />

From cab‐2 also CPs were working. As per ELS/GZB, cab‐1 panel was<br />

changed and loco given ready.<br />

Auto brake was already released. Again message of fault in brake<br />

electronics appeared. F 1001 P‐1. Put MCE OFF & ON and worked.<br />

Put MCE OFF & ON but not succeeded. Speed was picking upto 130<br />

kmph. After CHK throttle was not responding. Loco was sent dead to<br />

home shed.<br />

Put HPAR switch on bypass mode but not succeeded. Fresh loco<br />

given.<br />

ABB Material NCR<br />

ABB Material NCR<br />

ABB Material NCR<br />

Static Inverter Material NCR<br />

22 20‐Jun‐11 12875 22721 GZB NR ICDJ. Put HBA on 0 but not succeeded. As per troubleshooting Q 44 relay<br />

was getting de‐energised. Advised to move GR from 0 to 10 and then<br />

back but not succeeded. Tapped Q 30 relay but now QOP‐2 dropped<br />

permanently. Fresh loco given. As per report of GZB, loco was found<br />

normal.<br />

Control Circuit Misc NCR<br />

23 21‐Jun‐11 12877 22622 GZB NR MVSL‐2 not working. Fresh loco given. As per PPO/GZB, MVSL‐2 connecting cable wire was LT Cable Material NCR<br />

cut. Same was changed and given fit.<br />

24 22‐Jun‐11 HPU Dn 27770 AQ CR SIV AAL. Internal fault lamp was glowing. Put HBA on 0 for 3 minutes but not succeeded. Now put HRAVT on 0 Static Inverter Material NCR<br />

but still internal fault lamp was glowing. Fresh loco given.<br />

25 23‐Jun‐11 HSRA Up 31154 LGD SCR Bogie no‐2 was isolated. It was received ex PWL on half traction. Loco failed and fresh loco given. ABB Material NCR<br />

26 23‐Jun‐11 12945 22751 MGS ECR TFP oil not visible in gauge glass. No preintimation was given by TLC/TDL. This loco was received while TFP Maintenance NCR<br />

working in T.N. 12946. Fresh loco given.<br />

27 24‐Jun‐11 SOG Dn 23085 TKD WCR MU with 23566. CCDJ fuse melted in leading loco 23085 as CCDJ fuse Same changed and worked. Fuse Material NCR<br />

melted.<br />

28 24‐Jun‐11 TAPG Dn 27351 TKD WCR One end of cotter pin on wheel no‐11 equalising beam found broken. Same pin was taken out and refitted after proper machining and Bogie Item Material NCR<br />

grinding.<br />

29 25‐Jun‐11 18507 22030 GZB NR TM‐5 running warm. Loco was checked at ELS/JHS and it was found that suspension bearing Suspension Bearing Maintenance NCR<br />

oil level was below minimum mark. This caused SB metal out in TM‐5.<br />

Its TI was done at ASR on 22.6.11. Bad maintenance by TI shed.<br />

30 26‐Jun‐11 DDL Dn 27037 MGS ECR One end of the cotter pin on wheel no‐9 beam was broken. Cotter pin was provided and loco given ready. Bogie Item Material NCR<br />

31 26‐Jun‐11 14011 28321 BIA SECR ICDJ. MPCS (STESALIT) & SIV (SIEMENS) fitted loco. No fault lamp was glowing and message on BLDJ. Put HBA on 0 and<br />

HOBA on OFF. Checked all fuses and switches but not succeeded.<br />

Fresh loco given. As per DDS display unit of SIV unabled.<br />

Static Inverter Material NCR<br />

32 27‐Jun‐11 11078 22615 LDH NR Unusual sound coming from bogie no‐1 at a speed of 15 kmph. Fresh loco given at JHS station. Checked at ELS/JHS and no<br />

abnormality was found after dismantling gearcase no‐2. One staff was<br />

deputed for escort of the loco and no abnormality was found during<br />

run. Loco was sent to home shed.<br />

Gearcase Material NCR<br />

33 28‐Jun‐11 MXX Dn 31094 AQ CR MCB no 53.1/1 for traction motor blower tripped. Message F 1101 P‐2 Put MCE OFF & ON but same MCB tripped again. Loco worked on half ABB Material NCR<br />

appeared.<br />

traction.<br />

34 29‐Jun‐11 SOG Dn 27370 NKJ WCR Oil leakage from delivery pipe near MPH. On checking found there was a bent of 90 degrees and there was a<br />

slight crack at the bent point causing leakage. The threads of joint<br />

plug of MPH and copper pipe were slack causing leakage. It was<br />

leaking @ 120 drops per minute. Fresh loco given.<br />

Pipeline Material NCR<br />

35 30‐Jun‐11 13007 22863 HWH ER At HDL, LP reported that copper pipe in cab‐2 located below wiper cut<br />

out cock was leaking heavily.<br />

Tried to troubleshoot but could not. Fresh loco given. As per<br />

investigation, copper pipe material was weak which burst on its own.<br />

Pipeline Material NCR