Autopilot System Installation Instructions - New Holland PLM Portal

Autopilot System Installation Instructions - New Holland PLM Portal

Autopilot System Installation Instructions - New Holland PLM Portal

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

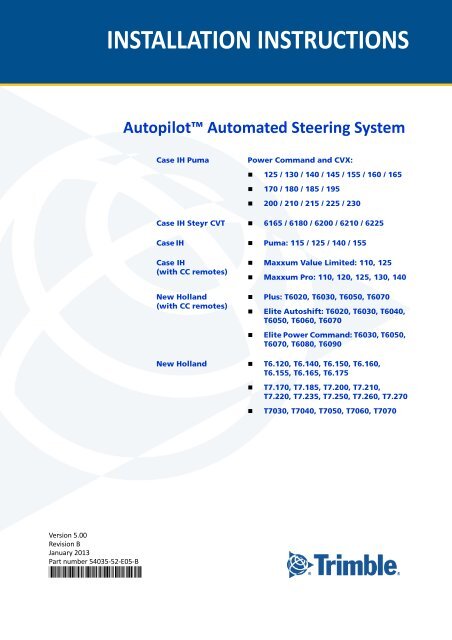

INSTALLATION INSTRUCTIONS<br />

<strong>Autopilot</strong> Automated Steering <strong>System</strong><br />

Case IH Puma<br />

Power Command and CVX:<br />

• 125 / 130 / 140 / 145 / 155 / 160 / 165<br />

• 170 / 180 / 185 / 195<br />

• 200 / 210 / 215 / 225 / 230<br />

Case IH Steyr CVT • 6165 / 6180 / 6200 / 6210 / 6225<br />

Case IH • Puma: 115 / 125 / 140 / 155<br />

Case IH<br />

(with CC remotes)<br />

<strong>New</strong> <strong>Holland</strong><br />

(with CC remotes)<br />

• Maxxum Value Limited: 110, 125<br />

• Maxxum Pro: 110, 120, 125, 130, 140<br />

• Plus: T6020, T6030, T6050, T6070<br />

• Elite Autoshift: T6020, T6030, T6040,<br />

T6050, T6060, T6070<br />

• Elite Power Command: T6030, T6050,<br />

T6070, T6080, T6090<br />

<strong>New</strong> <strong>Holland</strong> • T6.120, T6.140, T6.150, T6.160,<br />

T6.155, T6.165, T6.175<br />

• T7.170, T7.185, T7.200, T7.210,<br />

T7.220, T7.235, T7.250, T7.260, T7.270<br />

• T7030, T7040, T7050, T7060, T7070<br />

Version 5.00<br />

Revision B<br />

January 2013<br />

Part number 54035-52-E05-B<br />

*54035-52-E05-B*

Legal Notices<br />

Agriculture Business Area<br />

Trimble Agriculture Division<br />

10355 Westmoor Drive<br />

Suite #100<br />

Westminster, CO 80021<br />

USA<br />

trimble_support@trimble.com<br />

www.trimble.com<br />

Copyright and Trademarks<br />

© 1999–2012, Trimble Navigation Limited. All rights reserved.<br />

Trimble, the Globe & Triangle logo, AgGPS, and FmX are trademarks of<br />

Trimble Navigation Limited, registered in the United States and in other<br />

countries. <strong>Autopilot</strong>, Autosense, and CFX-750 are trademarks of<br />

Trimble Navigation Limited.<br />

Developed under a License of the European Union and the European<br />

Space Agency.<br />

All other trademarks are the property of their respective owners.<br />

Release Notice<br />

This is the January 2013 release (Revision B) of the <strong>Autopilot</strong><br />

Automated Steering <strong>System</strong> <strong>Installation</strong> <strong>Instructions</strong>, part number<br />

54035-52-E05-B. It applies to version 5.00 of the <strong>Autopilot</strong> automated<br />

steering system.<br />

The following limited warranties give you specific legal rights. You may<br />

have others, which vary from state/jurisdiction to state/jurisdiction.<br />

Product Limited Warranty<br />

Trimble warrants that this Trimble product and its internal components<br />

(the “Product”) shall be free from defects in materials and<br />

workmanship and will substantially conform to Trimble’s applicable<br />

published specifications for the Product for a period of one (1) year,<br />

starting from the earlier of (i) the date of installation, or (ii) six (6)<br />

months from the date of product shipment from Trimble. This<br />

warranty applies only to the Product if installed by Trimble or a<br />

distributor authorized by Trimble to perform Product installation<br />

services.<br />

Software Components and Enhancements<br />

All Product software components (sometimes hereinafter also referred<br />

to as “Software”) are licensed and not sold. Any Software accompanied<br />

by a separate End User License Agreement (“EULA”) shall be governed<br />

by the terms, conditions, restrictions and limited warranty terms of<br />

such EULA notwithstanding the preceding paragraph. During the<br />

limited warranty period you will be entitled to receive, at no additional<br />

charge, such Fix Updates and Minor Updates to the Product software<br />

as Trimble may develop for general release, subject to the procedures<br />

for delivery to purchasers of Trimble products generally. If you have<br />

purchased the Product from an authorized Trimble distributor rather<br />

than from Trimble directly, Trimble may, at its option, forward the<br />

software Fix Update or Minor Update to the Trimble distributor for<br />

final distribution to you. Major Upgrades, new products, or<br />

substantially new software releases, as identified by Trimble are<br />

expressly excused from this enhancement process and limited<br />

warranty. Receipt of software updates shall not serve to extend the<br />

limited warranty period.<br />

For purposes of this warranty the following definitions shall apply: (1)<br />

“Fix Update” means an error correction or other update created to fix<br />

a previous software version that does not substantially conform to its<br />

published specifications; (2) “Minor Update” occurs when<br />

enhancements are made to current features in a software program;<br />

and (3) “Major Upgrade” occurs when significant new features are<br />

added to software, or when a new product containing new features<br />

replaces the further development of a current product line. Trimble<br />

reserves the right to determine, in its sole discretion, what constitutes<br />

a significant new feature and Major Upgrade.<br />

Warranty Remedies<br />

Trimble’s sole liability and your exclusive remedy under the warranties<br />

set forth above shall be, at Trimble’s option, to repair or replace any<br />

Product that fails to conform to such warranty (“Nonconforming<br />

Product”), and/or issue a cash refund up to the purchase price paid by<br />

you for any such Nonconforming Product, excluding costs of<br />

installation, upon your return of the Nonconforming Product to<br />

Trimble in accordance with Trimble’s standard return material<br />

authorization process. Such remedy may include reimbursement of the<br />

cost of repairs for damage to third-party equipment onto which the<br />

Product is installed, if such damage is found to be directly caused by<br />

the Product as reasonably determined by Trimble following a root<br />

cause analysis.<br />

Warranty Exclusions and Disclaimer<br />

These warranties shall be applied only in the event and to the extent<br />

that (i) the Products and Software are properly and correctly installed,<br />

configured, interfaced, maintained, stored, and operated in<br />

accordance with Trimble's relevant operator's manual and<br />

specifications, and; (ii) the Products and Software are not modified or<br />

misused. The preceding warranties shall not apply to, and Trimble shall<br />

not be responsible for defects or performance problems resulting from<br />

(i) the combination or utilization of the Product or Software with<br />

hardware or software products, information, data, systems, interfaces<br />

or devices not made, supplied or specified by Trimble; (ii) the<br />

operation of the Product or Software under any specification other<br />

than, or in addition to, Trimble's standard specifications for its<br />

products; (iii) the unauthorized, installation, modification, or use of the<br />

Product or Software; (iv) damage caused by accident, lightning or<br />

other electrical discharge, fresh or salt water immersion or spray; or (v)<br />

normal wear and tear on consumable parts (e.g., batteries). Trimble<br />

does not warrant or guarantee the results obtained through the use of<br />

the Product.<br />

THE WARRANTIES ABOVE STATE TRIMBLE'S ENTIRE LIABILITY, AND YOUR<br />

EXCLUSIVE REMEDIES, RELATING TO PERFORMANCE OF THE PRODUCTS<br />

AND SOFTWARE. EXCEPT AS OTHERWISE EXPRESSLY PROVIDED HEREIN,<br />

THE PRODUCTS, SOFTWARE, AND ACCOMPANYING DOCUMENTATION AND<br />

MATERIALS ARE PROVIDED “AS-IS” AND WITHOUT EXPRESS OR IMPLIED<br />

WARRANTY OF ANY KIND BY EITHER TRIMBLE NAVIGATION LIMITED OR<br />

ANYONE WHO HAS BEEN INVOLVED IN ITS CREATION, PRODUCTION,<br />

INSTALLATION, OR DISTRIBUTION INCLUDING, BUT NOT LIMITED TO, THE<br />

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A<br />

PARTICULAR PURPOSE, TITLE, AND NONINFRINGEMENT. THE STATED<br />

EXPRESS WARRANTIES ARE IN LIEU OF ALL OBLIGATIONS OR LIABILITIES<br />

ON THE PART OF TRIMBLE ARISING OUT OF, OR IN CONNECTION WITH, ANY<br />

PRODUCTS OR SOFTWARE. SOME STATES AND JURISDICTIONS DO NOT<br />

ALLOW LIMITATIONS ON DURATION OR THE EXCLUSION OF AN IMPLIED<br />

WARRANTY, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.<br />

TRIMBLE NAVIGATION LIMITED IS NOT RESPONSIBLE FOR THE OPERATION<br />

OR FAILURE OF OPERATION OF GPS SATELLITES OR THE AVAILABILITY OF<br />

GPS SATELLITE SIGNALS.<br />

Limitation of Liability<br />

TRIMBLE’S ENTIRE LIABILITY UNDER ANY PROVISION HEREIN SHALL BE<br />

LIMITED TO THE AMOUNT PAID BY YOU FOR THE PRODUCT OR SOFTWARE<br />

LICENSE. TO THE MAXIMUM EXTENT PERMITTED BY APPLICABLE LAW, IN<br />

NO EVENT SHALL TRIMBLE OR ITS SUPPLIERS BE LIABLE FOR ANY<br />

INDIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES<br />

WHATSOEVER UNDER ANY CIRCUMSTANCE OR LEGAL THEORY RELATING<br />

IN ANY WAY TO THE PRODUCTS, SOFTWARE AND ACCOMPANYING<br />

DOCUMENTATION AND MATERIALS, (INCLUDING, WITHOUT LIMITATION,<br />

DAMAGES FOR LOSS OF BUSINESS PROFITS, BUSINESS INTERRUPTION, LOSS<br />

OF BUSINESS INFORMATION, OR ANY OTHER PECUNIARY LOSS),<br />

REGARDLESS WHETHER TRIMBLE HAS BEEN ADVISED OF THE POSSIBILITY<br />

OF ANY SUCH LOSS AND REGARDLESS OF THE COURSE OF DEALING WHICH<br />

DEVELOPS OR HAS DEVELOPED BETWEEN YOU AND TRIMBLE. BECAUSE<br />

SOME STATES AND JURISDICTIONS DO NOT ALLOW THE EXCLUSION OR<br />

LIMITATION OF LIABILITY FOR CONSEQUENTIAL OR INCIDENTAL<br />

DAMAGES, THE ABOVE LIMITATION MAY NOT APPLY TO YOU.<br />

NOTE: THE ABOVE LIMITED WARRANTY PROVISIONS MAY NOT APPLY TO<br />

PRODUCTS OR SOFTWARE PURCHASED IN THE EUROPEAN UNION. PLEASE<br />

CONTACT YOUR TRIMBLE DEALER FOR APPLICABLE WARRANTY<br />

INFORMATION.<br />

Notices<br />

Class B Statement – Notice to Users. This equipment has been tested<br />

and found to comply with the limits for a Class B digital device,<br />

pursuant to Part 15 of the FCC rules. These limits are designed to<br />

provide reasonable protection against harmful interference in a<br />

residential installation. This equipment generates, uses, and can<br />

radiate radio frequency energy and, if not installed and used in<br />

accordance with the instructions, may cause harmful interference to<br />

radio communication. However, there is no guarantee that<br />

interference will not occur in a particular installation. If this equipment<br />

does cause harmful interference to radio or television reception, which<br />

can be determined by turning the equipment off and on, the user is<br />

encouraged to try to correct the interference by one or more of the<br />

following measures:<br />

– Reorient or relocate the receiving antenna.<br />

– Increase the separation between the equipment and the receiver.<br />

– Connect the equipment into an outlet on a circuit different from<br />

that to which the receiver is connected.<br />

– Consult the dealer or an experienced radio/TV technician for help.<br />

Changes and modifications not expressly approved by the<br />

manufacturer or registrant of this equipment can void your authority<br />

to operate this equipment under Federal Communications Commission<br />

rules.<br />

Notice to Our European Union Customers<br />

For product recycling instructions and more information, please go to:<br />

www.trimble.com/ev.shtml<br />

Recycling in Europe: To recycle Trimble WEEE, Call<br />

+31 497 53 2430, and ask for the "WEEE Associate"<br />

Or<br />

Mail a request for recycling instructions to:<br />

Trimble Europe BV<br />

c/o Menlo Worldwide Logistics<br />

Meerheide 45<br />

5521 DZ Eersel, NL<br />

AUTOPILOT AUTOMATED STEERING SYSTEM INSTALLATION INSTRUCTIONS 2

Safety Information<br />

Always follow the instructions that accompany a Warning or Caution. The information they provide is<br />

intended to minimize the risk of personal injury and/or damage to property. In particular, observe<br />

safety instructions that are presented in the following format:<br />

C<br />

C<br />

WARNING – This alert warns of a potential hazard, which, if not avoided, can cause severe<br />

injury.<br />

CAUTION – This alert warns of a hazard or unsafe practice which, if not avoided, can cause<br />

injury or damage.<br />

Note – An absence of specific alerts does not mean that there are no safety risks involved.<br />

Warnings<br />

C<br />

WARNING – When you are working on the vehicle’s hydraulic systems, vehicle attachments<br />

that are suspended can drop. If you are working around the vehicle, you could suffer serious<br />

injury if an attachment dropped on you. To avoid this risk, lower all vehicle attachments to the<br />

ground before you begin work.<br />

C<br />

C<br />

C<br />

WARNING – If someone else attempts to drive the vehicle while you are working on or under<br />

it, you can suffer serious or fatal injuries. To avoid this possibility, install a lockout box on the<br />

battery terminal to prevent the battery from being reconnected, remove the key from the<br />

vehicle’s ignition switch, and attach a “Do not operate” tag in the cab.<br />

WARNING – Agricultural chemicals can pose serious health risks. If the vehicle has been used<br />

to apply agricultural chemicals, steam clean the vehicle to remove any chemical residue from<br />

the areas of the vehicle where you will be working.<br />

WARNING – Vehicle cabs can be quite high in the air. To avoid potentially serious injury<br />

through falling from this height, always use the steps and handrails, and face the vehicle, when<br />

you enter or exit it.<br />

AUTOPILOT AUTOMATED STEERING SYSTEM INSTALLATION INSTRUCTIONS 3

– Safety Information<br />

Cautions<br />

C<br />

CAUTION – When the vehicle has been running, parts of the vehicle, including the engine and<br />

exhaust, can become extremely hot and can cause serious burns. To avoid burns, allow hot<br />

machine parts to cool before you begin working on them.<br />

C<br />

C<br />

C<br />

C<br />

C<br />

CAUTION – The system installation may bring you into contact with chemical substances, such<br />

as oil, which can cause poisoning. Wash your hands thoroughly after you finish working on the<br />

system.<br />

CAUTION – Battery posts, terminals, and related accessories contain lead and lead<br />

compounds, which can cause serious illness. To avoid ingesting lead, wash your hands<br />

thoroughly after touching the battery.<br />

CAUTION – Always wear protective equipment appropriate to the job conditions and the<br />

nature of the vehicle. This includes wearing protective glasses when you use pressurized air or<br />

water, and correct protective welder’s clothing when welding. Avoid wearing loose clothing or<br />

jewelry that can catch on machine parts or tools.<br />

CAUTION – Parts of the vehicle may be under pressure. To avoid injury from pressurized parts,<br />

relieve all pressure in oil, air, and water systems before you disconnect any lines, fittings, or<br />

related items. To avoid being sprayed by pressurized liquids, hold a rag over fill caps, breathers,<br />

or hose connections when you remove them. Do not use your bare hands to check for<br />

hydraulic leaks. Use a board or cardboard instead.<br />

CAUTION – Do not direct pressurized water at:<br />

- electronic or electrical components or connectors<br />

- bearings<br />

- hydraulic seals<br />

- fuel injection pumps<br />

- any other sensitive parts or components<br />

Set the hose pressure as low as practicable, and spray at a 45° to 90° angle. Keep the nozzle of<br />

the power washer away from the machine at the distance recommended by the manufacturer.<br />

AUTOPILOT AUTOMATED STEERING SYSTEM INSTALLATION INSTRUCTIONS<br />

4

Contents<br />

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3<br />

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3<br />

Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4<br />

1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7<br />

Technical assistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7<br />

Manual system upgrade to <strong>Autopilot</strong> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8<br />

FmX integrated display and CFX-750 display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8<br />

Required components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8<br />

Antenna mounting kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8<br />

Accessory kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8<br />

<strong>Autopilot</strong> hardware organization: As shipped . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9<br />

Preparing the vehicle for installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10<br />

2 Hydraulic Control Valve <strong>Installation</strong>. . . . . . . . . . . . . . . . . . . . . . . . . . . 11<br />

Vehicle types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12<br />

Hydraulic control valve components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13<br />

Assembling the hydraulic control valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14<br />

Preparing the counterbalance valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18<br />

Installing the <strong>Autopilot</strong> manifold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20<br />

Option A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20<br />

Option B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23<br />

Option C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26<br />

Option D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28<br />

Installing the counterbalance valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29<br />

Option 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30<br />

Option 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31<br />

Option 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34<br />

Making the hydraulic hose connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35<br />

Steering line connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36<br />

Connecting the steering lines to the counterbalance valve . . . . . . . . . . . . . . . . . . . . . . . . .37<br />

Option A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38<br />

Option B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40<br />

Pressure, Tank, and LS connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42<br />

Connections for Type 1 machines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42<br />

Connections for Type 2 machines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47<br />

Connecting P, T and LS to the <strong>Autopilot</strong> manifold. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53<br />

3 Autosense Steering Device <strong>Installation</strong> . . . . . . . . . . . . . . . . . . . . . . . . . 55<br />

Autosense steering device components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56<br />

Installing the Autosense steering device. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57<br />

Preparing the harness (P/N 54602 Rev C) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60<br />

4 Antenna/External Receiver (If Used) <strong>Installation</strong> . . . . . . . . . . . . . . . . . . . 62<br />

Antenna and receiver installation options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63<br />

Possible mounting methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63<br />

AUTOPILOT AUTOMATED STEERING SYSTEM INSTALLATION INSTRUCTIONS 5

Mounting an adjustable spar to roof bolts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64<br />

Attaching the plate with VHB adhesive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66<br />

AG-372 receiver with AgGPS 450/900 radio module (if equipped) components . . . . . . . . . . . . . .69<br />

Installing the AG-372 GPS receiver with<br />

AgGPS 450/900 radio module (if equipped) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70<br />

Removable installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70<br />

Permanent installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71<br />

Installing an AG-372 receiver with magnetic feet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76<br />

AgGPS 542 receiver components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78<br />

Installing the AgGPS 542 receiver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79<br />

5 Display <strong>Installation</strong> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82<br />

CFX-750 display components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83<br />

FmX integrated display components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84<br />

Preparing the CFX-750 display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85<br />

Installing the CFX-750 display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86<br />

CFX-750 display: Installing the wiring harness. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86<br />

Preparing the FmX integrated display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87<br />

Installing the FmX integrated display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88<br />

FmX integrated display: Installing the wiring harness . . . . . . . . . . . . . . . . . . . . . . . . . . . .89<br />

CFX-750 display and FmX integrated display: Connecting accessory options . . . . . . . . . . . . . . . .90<br />

AgCam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90<br />

CFX-750 and FmX displays: Installing the GNSS antenna and plate . . . . . . . . . . . . . . . . . . . . .92<br />

Spar mount method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .92<br />

VHB adhesive method. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .92<br />

CFX-750 and FmX displays: Installing the RTK radio antenna. . . . . . . . . . . . . . . . . . . . . . . . .96<br />

6 Power Harness <strong>Installation</strong> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97<br />

FmX integrated display components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .98<br />

CFX-750 display components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99<br />

FmX and CFX-750 displays: Installing the power harness. . . . . . . . . . . . . . . . . . . . . . . . . . 101<br />

FmX and CFX-750 displays: Configuring the power bus options . . . . . . . . . . . . . . . . . . . . . . 103<br />

Display power button is used to turn on the <strong>Autopilot</strong> system . . . . . . . . . . . . . . . . . . . . 103<br />

External switch is used to turn on the <strong>Autopilot</strong> system . . . . . . . . . . . . . . . . . . . . . . . . 103<br />

Ignition is used to turn on the <strong>Autopilot</strong> system . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105<br />

7 Remote Engage Switch <strong>Installation</strong> . . . . . . . . . . . . . . . . . . . . . . . . . . .106<br />

Remote engage switch components: Rocker switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107<br />

Remote engage switch components: Foot switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108<br />

Preparing the remote engage cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109<br />

Using the remote engage switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112<br />

8 Controller <strong>Installation</strong> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .113<br />

Installing the controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114<br />

Back method: When the rear ECU slot is free . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114<br />

Seat mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119<br />

Installing the controller cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129<br />

Controller connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130<br />

9 Final Machine Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .133<br />

AUTOPILOT AUTOMATED STEERING SYSTEM INSTALLATION INSTRUCTIONS 6

CHAPTER<br />

1<br />

Introduction 1<br />

In this chapter:<br />

• Technical assistance<br />

• Manual system upgrade to <strong>Autopilot</strong><br />

• Required components<br />

• <strong>Autopilot</strong> hardware organization: As shipped<br />

• Preparing the vehicle for installation<br />

This manual describes how to install the<br />

Trimble ® <strong>Autopilot</strong> automated steering<br />

system.<br />

Even if you have used other Global Navigation<br />

Satellite <strong>System</strong> (GNSS) such as the United<br />

States', Trimble recommends that you spend<br />

some time reading this manual to learn about<br />

the special features of this product. If you are<br />

not familiar with GNSS, visit the Trimble website<br />

(www.trimble.com) for an interactive look at<br />

Trimble and GNSS.<br />

Technical assistance<br />

If you have a problem and cannot find the information you need in the product documentation,<br />

contact Trimble technical support:<br />

1. Log into http://agpartners.trimble.com.<br />

2. Click the Feedback link at the right of the screen. A form appears.<br />

3. Complete the form and then click Submit Feedback.<br />

AUTOPILOT AUTOMATED STEERING SYSTEM INSTALLATION INSTRUCTIONS 7

1 – Introduction<br />

Manual system upgrade to <strong>Autopilot</strong><br />

FmX integrated display and CFX-750 display<br />

Retain<br />

Trimble FmX ® integrated display: P/N 93000-xx<br />

Antenna for display: P/N 60600-02 (DGPS) or<br />

77038-00 (OmniStar/RTK)<br />

Antenna to receiver cable: P/N 50449<br />

Power cable FmX® integrated display:<br />

P/N 66694<br />

Trimble CFX-750 display: P/N 94000-xx<br />

Power cable CFX-750 display: P/N 77282<br />

Basic cable (both displays): P/N 67258<br />

Remove<br />

Required components<br />

Kits required<br />

Platform kit: P/N 54035-52<br />

Hydraulic hose kit: P/N 63579<br />

Special tools<br />

10.5 mm drill bit<br />

Allen wrench set (metric and imperial)<br />

Antenna mounting kits<br />

Kits required<br />

Select the spar mount that is correct for your tractor model, based on the measurements below. For more<br />

information, see page 64.<br />

Bracket, GPS spar 36.5" - 46.5": P/N 53676<br />

Bracket, GPS spar 54" - 64”: P/N 66774<br />

Accessory kits<br />

Accessory options<br />

Remote engage switch assembly – standard Euro: P/N 57227-10<br />

Remote engage switch assembly – full Euro: P/N 57227-20<br />

Remote engage foot pedal: P/N 57259<br />

AUTOPILOT AUTOMATED STEERING SYSTEM INSTALLATION INSTRUCTIONS<br />

8

1 – Introduction<br />

<strong>Autopilot</strong> hardware organization: As shipped<br />

Hardware Component See...<br />

Platform kit: P/N 54035-52<br />

Hydraulic valve<br />

Hydraulic manifold<br />

Transducer flow switch<br />

Manual override cable<br />

Hydraulic brackets and bolt kits<br />

Hydraulic valve cable<br />

Autosense steering device and cabling<br />

Autosense mounting bracket and hardware<br />

Chapter 2<br />

Chapter 3<br />

Power switch Chapter 6<br />

Bolt kit controller Chapter 8<br />

Common parts Controller Chapter 8<br />

GNSS receiver<br />

Display<br />

Hydraulic hose kit: P/N 63579<br />

Roof bracket kit: P/N 62388-02<br />

Bracket, GPS spar 36.5" - 46.5":<br />

P/N 53676<br />

Bracket, GPS spar 54" - 64:<br />

P/N 66774<br />

Controller mounting bracket Chapter 1<br />

Cable kit:<br />

• Main wiring harness<br />

• Power bus auxiliary wiring harness<br />

• Sonalert alarm<br />

GNSS receiver<br />

GNSS antenna<br />

GNSS receiver power/data cable<br />

RTK radio, cable, and radio antenna<br />

FmX integrated display<br />

CFX-750 display<br />

Display cable<br />

Mounting bracket<br />

Hydraulic hoses<br />

Hydraulic adaptors<br />

Roof brackets<br />

Bolt kit, roof bracket<br />

Chapter 8<br />

Chapter 4<br />

Chapter 5<br />

Chapter 2<br />

Chapter 4<br />

AUTOPILOT AUTOMATED STEERING SYSTEM INSTALLATION INSTRUCTIONS<br />

9

1 – Introduction<br />

Preparing the vehicle for installation<br />

1. Park the vehicle on a hard, level surface. Block the front and rear wheels.<br />

2. Align the steering straight ahead. On an articulated vehicle, install the articulation locks.<br />

3. Remove all dirt and debris from the areas of the vehicle where the <strong>Autopilot</strong> system will be<br />

installed.<br />

4. Open all kit boxes and check the contents of the box against the packing list/s. Lay all of the parts<br />

out on a clean workbench.<br />

Note – The left and right sides of the vehicle are referenced while standing behind the unit, facing the<br />

normal direction of travel.<br />

AUTOPILOT AUTOMATED STEERING SYSTEM INSTALLATION INSTRUCTIONS<br />

10

CHAPTER<br />

2<br />

Hydraulic Control Valve <strong>Installation</strong> 2<br />

In this chapter:<br />

• Vehicle types<br />

• Hydraulic control valve components<br />

• Assembling the hydraulic control valve<br />

• Preparing the counterbalance valve<br />

• Installing the <strong>Autopilot</strong> manifold<br />

• Installing the counterbalance valve<br />

• Making the hydraulic hose connections<br />

• Connecting the steering lines to the<br />

counterbalance valve<br />

• Pressure, Tank, and LS connections<br />

• Connecting P, T and LS to the <strong>Autopilot</strong><br />

manifold<br />

This chapter describes how to install the<br />

hydraulic control valve and hoses.<br />

AUTOPILOT AUTOMATED STEERING SYSTEM INSTALLATION INSTRUCTIONS 11

2 – Hydraulic Control Valve <strong>Installation</strong><br />

Vehicle types<br />

Depending on the type of machine that you use, select the appropriate installation option to<br />

configure the <strong>Autopilot</strong> valve.<br />

Machine<br />

type<br />

Valve configuration<br />

1. The LS check valve is inserted in<br />

the GP-LS2 port in the H3 valve.<br />

2. The 160 psi Pcomp cartridge is<br />

inserted into the valve.<br />

Valve stack description<br />

Vehicle remotes are split into two columns; one on<br />

each side of the upper three-point link.<br />

1<br />

2<br />

1. The LS Check valve is removed<br />

from the GP-LS2 port in the H3<br />

valve and replaced with a -4ORB<br />

plug<br />

2. The 80 psi Pcomp cartridge is<br />

inserted into the valve.<br />

Vehicle remotes are in one column on the right side<br />

of the tractor.<br />

AUTOPILOT AUTOMATED STEERING SYSTEM INSTALLATION INSTRUCTIONS<br />

12

2 – Hydraulic Control Valve <strong>Installation</strong><br />

Hydraulic control valve components<br />

k<br />

n<br />

q<br />

s<br />

i<br />

h<br />

c<br />

e<br />

f<br />

k<br />

j<br />

u<br />

q<br />

j<br />

p<br />

g<br />

n<br />

f<br />

d<br />

l<br />

j<br />

j<br />

r<br />

o<br />

f<br />

p<br />

f<br />

Item Description Part number Item Description Part number<br />

c 113" hose F451TCJSJ9-08-08-08-113 m Fitting (not shown) 4 HP50N-S<br />

d 113" hose F451TCJSJ7-08-08-08-113 n Fitting (x2) 8 FNL-S<br />

e 113" hose F451TCJSJ7-04-04-04-113 o Fitting 4F5OLO-S<br />

f 28" hose (x4) F451TCJSJ9-06-06-06-28 p Fitting (x2) 6R6LO-S<br />

g Fitting 8-12F42EDMLO q Fitting (x2) 8R6LO-S<br />

h Fitting 8M22F87OMLO-S r Fitting 8C5OLO-S<br />

i Fitting 4M12F87OMLO-S s Fitting 4C6LO-S<br />

j Fitting (x4) 6-8F5OLO-S t Fitting (not shown) HP-B-13-RFL<br />

k Fitting (x2) 6-8C5OLO-S u Fitting 8M27F870ML0<br />

l Fitting 8F5OLO-S<br />

Note – Part numbers are Parker numbers and are for reference only.<br />

AUTOPILOT AUTOMATED STEERING SYSTEM INSTALLATION INSTRUCTIONS<br />

13

2 – Hydraulic Control Valve <strong>Installation</strong><br />

Assembling the hydraulic control valve<br />

WARNING – To avoid potentially serious personal injury or illness, and to prevent damage to<br />

Cequipment, make sure that you read and understand the Safety Information chapter.<br />

Step 1<br />

Place the hydraulic control valve and<br />

components on a clean working<br />

surface, including the 300 PSI pressure<br />

compensation valve and the 300 PSI<br />

check valve.<br />

Step 2<br />

Remove the existing check valve from<br />

above the T port as shown.<br />

Step 3<br />

Install the supplied 300 PSI check valve,<br />

which is stamped “CV1-10-P-0-300”.<br />

AUTOPILOT AUTOMATED STEERING SYSTEM INSTALLATION INSTRUCTIONS<br />

14

2 – Hydraulic Control Valve <strong>Installation</strong><br />

Step 4<br />

Install the following fittings in the ports<br />

as shown:<br />

• -8 ORFS 90 degree elbow with jam<br />

nut c into the T port.<br />

Note – Keep the jam nut loose for now.<br />

• -4 ORFS straight d into the LS2 port.<br />

c<br />

d<br />

Step 5<br />

There are two options for the check<br />

valve installed in the GP-LS2 port; the<br />

option that you use will depend on the<br />

type of machine you have.<br />

To determine the correct option to use,<br />

see Vehicle types, page 12.<br />

Machine type 1<br />

If it is not already fitted, install the<br />

check valve in the port, as shown.<br />

Machine type 2<br />

If it is already fitted, remove the check<br />

valve.<br />

Step 6<br />

Install a -4 ORFS plug in place of the<br />

check valve.<br />

AUTOPILOT AUTOMATED STEERING SYSTEM INSTALLATION INSTRUCTIONS<br />

15

2 – Hydraulic Control Valve <strong>Installation</strong><br />

Step 7<br />

Install two -6 ORFS straight fittings into<br />

the A and B ports.<br />

Step 8<br />

Determine the best option for the<br />

vehicle and install either a -8 ORFS<br />

straight fitting or a -8 ORS-ORB 90°<br />

fitting in the P port.<br />

AUTOPILOT AUTOMATED STEERING SYSTEM INSTALLATION INSTRUCTIONS<br />

16

2 – Hydraulic Control Valve <strong>Installation</strong><br />

Step 9<br />

Locate the pressure compensation<br />

cartridge.<br />

There are two options for the pressure<br />

compensation cartridge; the option<br />

that you use will depend on the type of<br />

machine you have.<br />

To determine the correct option to use,<br />

see Vehicle types, page 12.<br />

Machine type 1<br />

Use the cartridge stamped<br />

“DPS2-10-F-F-0-160”.<br />

Machine type 2<br />

Use the cartridge stamped<br />

“DPS2-10-F-F-0-080”.<br />

Step 10<br />

Insert the P-Comp cartridge into the<br />

P-Comp port.<br />

Note – To seal the cavity correctly, the<br />

o-rings and backup rings must be clean<br />

and in place.<br />

AUTOPILOT AUTOMATED STEERING SYSTEM INSTALLATION INSTRUCTIONS<br />

17

2 – Hydraulic Control Valve <strong>Installation</strong><br />

Preparing the counterbalance valve<br />

Step 1<br />

Locate the dual counterbalance valve<br />

(DCBV) and fittings. Remove any plastic<br />

caps.<br />

Step 2<br />

Install a -6 ORFS, 90° fitting into the V1<br />

and V2 ports.<br />

For more information about the<br />

orientation of the fitting, see<br />

Connecting P, T and LS to the <strong>Autopilot</strong><br />

manifold, page 53.<br />

Step 3<br />

Install -6 ORFS straight connectors c<br />

into the C1 and C2 ports.<br />

Attach -6 ORFS swivel tees d to each of<br />

the straight connectors on the C1 and<br />

C2 ports.<br />

For more information about the<br />

orientation of the fittings, see<br />

Connecting P, T and LS to the <strong>Autopilot</strong><br />

manifold, page 53<br />

c d<br />

c<br />

d<br />

AUTOPILOT AUTOMATED STEERING SYSTEM INSTALLATION INSTRUCTIONS<br />

18

2 – Hydraulic Control Valve <strong>Installation</strong><br />

Step 4<br />

Connect the pressure sensor to the<br />

counterbalance manifold.<br />

AUTOPILOT AUTOMATED STEERING SYSTEM INSTALLATION INSTRUCTIONS<br />

19

2 – Hydraulic Control Valve <strong>Installation</strong><br />

Installing the <strong>Autopilot</strong> manifold<br />

There are different possible locations for mounting both the H3 valve and the DCBV, depending on<br />

the locations available on your vehicle. Review the options and then choose the location that the<br />

space configuration on your machine allows.<br />

Option A<br />

Step 1<br />

Locate the area in front of the machine<br />

ECU mounting plate. Mount the<br />

<strong>Autopilot</strong> manifold in this location.<br />

Step 2<br />

Install the <strong>Autopilot</strong> manifold in the<br />

location shown.<br />

Step 3<br />

Use the <strong>Autopilot</strong> manifold to carefully<br />

mark the location of the mounting<br />

holes.<br />

AUTOPILOT AUTOMATED STEERING SYSTEM INSTALLATION INSTRUCTIONS<br />

20

2 – Hydraulic Control Valve <strong>Installation</strong><br />

Step 4<br />

Before drilling holes in the ECU<br />

mounting plate, unbolt the ECU from<br />

the machine.<br />

Make sure that you remove the ECU at<br />

this step so that it is not damaged when<br />

you drill the holes for mounting the<br />

<strong>Autopilot</strong> manifold.<br />

Removing the ECU also provides access<br />

to the mounting hardware.<br />

AUTOPILOT AUTOMATED STEERING SYSTEM INSTALLATION INSTRUCTIONS<br />

21

2 – Hydraulic Control Valve <strong>Installation</strong><br />

Step 5<br />

Drill two 7 / 16 " holes for the supplied 3 / 8 "<br />

manifold mounting hardware.<br />

Mount the manifold to the ECU<br />

mounting plate then reattach the<br />

engine ECU to the mounting plate.<br />

AUTOPILOT AUTOMATED STEERING SYSTEM INSTALLATION INSTRUCTIONS<br />

22

2 – Hydraulic Control Valve <strong>Installation</strong><br />

Option B<br />

Step 1<br />

Locate the area in front of the machine<br />

ECU mounting plate. Mount the<br />

<strong>Autopilot</strong> manifold in this location.<br />

Step 2<br />

On some machines this valve is in the<br />

location of the <strong>Autopilot</strong> manifold<br />

mounting; to install the <strong>Autopilot</strong><br />

manifold relocate this valve to an<br />

alternate location that is out of the way.<br />

Step 3<br />

Use the <strong>Autopilot</strong> manifold to carefully<br />

mark the location of the mounting<br />

holes.<br />

AUTOPILOT AUTOMATED STEERING SYSTEM INSTALLATION INSTRUCTIONS<br />

23

2 – Hydraulic Control Valve <strong>Installation</strong><br />

Step 4<br />

Make sure that the marked holes do<br />

not interfere with the mounting bosses<br />

for the machine ECU on the other side<br />

of the plate.<br />

Before drilling holes in the ECU<br />

mounting plate, unbolt the ECU from<br />

the machine. Make sure that you<br />

remove the ECU at this step so that it is<br />

not damaged when you drill the holes<br />

for mounting the <strong>Autopilot</strong> manifold.<br />

Removing the ECU also provides access<br />

to the mounting hardware.<br />

Step 5<br />

Drill two 7 / 16 " holes for the supplied 3 / 8 "<br />

manifold mounting hardware.<br />

Mount the manifold to the ECU<br />

mounting plate then re attach the<br />

engine ECU to the mounting plate..<br />

AUTOPILOT AUTOMATED STEERING SYSTEM INSTALLATION INSTRUCTIONS<br />

24

2 – Hydraulic Control Valve <strong>Installation</strong><br />

AUTOPILOT AUTOMATED STEERING SYSTEM INSTALLATION INSTRUCTIONS<br />

25

2 – Hydraulic Control Valve <strong>Installation</strong><br />

Option C<br />

Step 1<br />

Mark and drill two 5 / 16 " holes<br />

approximately 5 ¼" inches apart. The<br />

holes should be drilled on the metal<br />

support angle pieces under the hood of<br />

the machine in front of the cab.<br />

Step 2<br />

Mount the counterbalance manifold<br />

mounting plate to the <strong>Autopilot</strong><br />

manifold as shown.<br />

Step 3<br />

Attach the counterbalance manifold to<br />

the mounting plate using the provided<br />

hardware. Assemble two<br />

-6 run T-fittings to the fittings on the C1<br />

c and C2 d ports of the manifold.<br />

d<br />

c<br />

AUTOPILOT AUTOMATED STEERING SYSTEM INSTALLATION INSTRUCTIONS<br />

26

2 – Hydraulic Control Valve <strong>Installation</strong><br />

Step 4<br />

Attach the <strong>Autopilot</strong> manifold and the<br />

counterbalance manifold assembly to<br />

the tractor using the provided<br />

hardware.<br />

AUTOPILOT AUTOMATED STEERING SYSTEM INSTALLATION INSTRUCTIONS<br />

27

2 – Hydraulic Control Valve <strong>Installation</strong><br />

Option D<br />

Some machines require the <strong>Autopilot</strong> manifold be installed on the right-side hood support rail<br />

instead of the standard left-side rail.<br />

Step 1<br />

Mark and drill two 5 / 16 " holes<br />

approximately 5 ¼" inches apart, on the<br />

right-hand side hood support rail c.<br />

c<br />

Step 2<br />

Use the provided hardware to attach<br />

the <strong>Autopilot</strong> manifold to the machine.<br />

AUTOPILOT AUTOMATED STEERING SYSTEM INSTALLATION INSTRUCTIONS<br />

28

2 – Hydraulic Control Valve <strong>Installation</strong><br />

Installing the counterbalance valve<br />

There are three options for installing the DCBV; the option that you use will depend on the type of<br />

machine that you have.<br />

Option 1<br />

Step 1<br />

On the right side of the machine locate<br />

the ECU mounting plate.<br />

Fit the DCBV to the side of the<br />

mounting plate.<br />

Step 2<br />

Use the DCBV as a template to mark<br />

and drill two 5 / 16 " holes.<br />

Step 3<br />

Use the supplied ¼” hardware to attach<br />

to the ECU mounting plate .<br />

AUTOPILOT AUTOMATED STEERING SYSTEM INSTALLATION INSTRUCTIONS<br />

29

2 – Hydraulic Control Valve <strong>Installation</strong><br />

Option 2<br />

Step 1<br />

Install the DCBV under the hood<br />

mounting area on the machine. Use<br />

the DCBV as a template to mark the<br />

location to drill two mounting holes.<br />

Step 2<br />

The hole on the left side of the machine<br />

should be approximately 2 inches from<br />

the plate (as shown), and ¾" from the<br />

edge of the mounting surface.<br />

Two inches<br />

AUTOPILOT AUTOMATED STEERING SYSTEM INSTALLATION INSTRUCTIONS<br />

30

2 – Hydraulic Control Valve <strong>Installation</strong><br />

3/4 inch<br />

Step 3<br />

Drill two 5 / 16 ” mounting holes.<br />

AUTOPILOT AUTOMATED STEERING SYSTEM INSTALLATION INSTRUCTIONS<br />

31

2 – Hydraulic Control Valve <strong>Installation</strong><br />

Step 4<br />

Use the supplied hardware to attach<br />

the DCBV.<br />

AUTOPILOT AUTOMATED STEERING SYSTEM INSTALLATION INSTRUCTIONS<br />

32

2 – Hydraulic Control Valve <strong>Installation</strong><br />

Option 3<br />

Step 1<br />

Mount the counterbalance manifold<br />

next to the <strong>Autopilot</strong> manifold as<br />

shown.<br />

Step 2<br />

Mark and drill a 5 / 16 " hole at c and<br />

then use the supplied hardware to<br />

mount the dual counterbalance valve.<br />

c<br />

AUTOPILOT AUTOMATED STEERING SYSTEM INSTALLATION INSTRUCTIONS<br />

33

2 – Hydraulic Control Valve <strong>Installation</strong><br />

Making the hydraulic hose connections<br />

Steering line connections<br />

Step 1<br />

Locate the clamped steel lines on the<br />

left side of the engine. Label the upper<br />

line and hose as B and the lower line<br />

and hose as A, as shown.<br />

Disconnect the hoses.<br />

L<br />

M<br />

Step 2<br />

Disconnect the steering hoses from the<br />

A and B hard lines. Route the steering<br />

hoses to the V1 and V2 ports of the<br />

DCBV.<br />

L<br />

M<br />

Step 3<br />

Connect the C1 c and C2 d hoses to<br />

the A and B hard lines, where the hoses<br />

were removed from in Step 2 above.<br />

Route the C1 and C2 hoses to the C1<br />

and C2 ports of the DCBV.<br />

c<br />

d<br />

AUTOPILOT AUTOMATED STEERING SYSTEM INSTALLATION INSTRUCTIONS<br />

34

2 – Hydraulic Control Valve <strong>Installation</strong><br />

Connecting the steering lines to the counterbalance<br />

valve<br />

There are two options for connecting the steering lines to the dual counterbalance valve (DCBV); the<br />

option that you use will depend on the type of machine that you have.<br />

Option A<br />

Step 1<br />

Route the existing machine hoses<br />

(removed from the hard lines in<br />

Steering line connections, page 36) to<br />

the V1 and V2 ports of the DCBV.<br />

Connect the A line to the V1 port, and<br />

the B line to the V2 port.<br />

V2<br />

V1<br />

Step 2<br />

Connect the 90° ends of the C1 and C2<br />

hoses to the end of the run tee fittings<br />

on the C1 and C2 ports of the DCBV<br />

manifold.<br />

C2<br />

C1<br />

Step 3<br />

Connect the 90° ends of the A and B<br />

hoses to the branch of the run tee<br />

fittings on the C1 and C2 ports of the<br />

DCBV manifold.<br />

M<br />

L<br />

AUTOPILOT AUTOMATED STEERING SYSTEM INSTALLATION INSTRUCTIONS<br />

35

2 – Hydraulic Control Valve <strong>Installation</strong><br />

Step 4<br />

Route the A and B hoses to the A and B<br />

ports of the <strong>Autopilot</strong> manifold and<br />

then connect them to the fittings on<br />

the A and B ports.<br />

AUTOPILOT AUTOMATED STEERING SYSTEM INSTALLATION INSTRUCTIONS<br />

36

2 – Hydraulic Control Valve <strong>Installation</strong><br />

Option B<br />

Step 1<br />

Connect the straight ends of the A and<br />

B hoses to the branches of the run tee<br />

fittings on the C1 and C2 ports of the<br />

DCBV.<br />

L M<br />

Step 2<br />

Connect the 90° ends of the C1 and C2<br />

hoses to the end of the run tee fittings<br />

on the C1 and C2 ports of the DCBV.<br />

Step 3<br />

Connect the machines steering lines<br />

(removed from the hard lines in<br />

Steering line connections, page 36) to<br />

the V1 and V2 ports of the DCBV<br />

manifold.<br />

V2<br />

V1<br />

AUTOPILOT AUTOMATED STEERING SYSTEM INSTALLATION INSTRUCTIONS<br />

37

2 – Hydraulic Control Valve <strong>Installation</strong><br />

Step 4<br />

Connect the 90° ends of the A and B<br />

hoses to the fittings on the A and B<br />

ports of the <strong>Autopilot</strong> manifold.<br />

AUTOPILOT AUTOMATED STEERING SYSTEM INSTALLATION INSTRUCTIONS<br />

38

2 – Hydraulic Control Valve <strong>Installation</strong><br />

Pressure, Tank, and LS connections<br />

Depending on the type of machine that you have, use one of the following options. To determine the<br />

correct option to use, see Vehicle types, page 12.<br />

Connections for Type 1 machines<br />

Step 1<br />

Locate the Power Beyond P and LS<br />

ports on the valve stack at the rear of<br />

the tractor.<br />

LS<br />

P<br />

For machines with electronic remotes:<br />

• c Load sense<br />

• d Pressure<br />

c<br />

d<br />

Step 2<br />

Remove the plug from the P port and<br />

install a -8 ORFS straight fitting.<br />

Remove the plug from the LS port and<br />

install a -4 ORFS straight fitting.<br />

AUTOPILOT AUTOMATED STEERING SYSTEM INSTALLATION INSTRUCTIONS<br />

39

2 – Hydraulic Control Valve <strong>Installation</strong><br />

Step 3<br />

Install a -8 swivel tee on the P port and<br />

a -8 ORFS plug to the run side of the<br />

tee.<br />

Step 4<br />

Install a -4 ORFS 90° elbow in the<br />

LS port.<br />

Step 5<br />

Locate the T port c at the back of the<br />

tractor, underneath the valve stack.<br />

c<br />

AUTOPILOT AUTOMATED STEERING SYSTEM INSTALLATION INSTRUCTIONS<br />

40

2 – Hydraulic Control Valve <strong>Installation</strong><br />

Step 6<br />

Install a -8 straight fitting into the<br />

T port.<br />

Step 7<br />

Install a -8 swivel tee on the T port and<br />

a -8 ORFS plug to the run side of the<br />

tee.<br />

Step 8<br />

Locate the provided 113" P hose, the<br />

113" T hose, and the 113" LS2 hose.<br />

Route them underneath the cab from<br />

the back of the tractor toward the<br />

<strong>Autopilot</strong> manifold.<br />

AUTOPILOT AUTOMATED STEERING SYSTEM INSTALLATION INSTRUCTIONS<br />

41

2 – Hydraulic Control Valve <strong>Installation</strong><br />

Step 9<br />

Connect the 45° end of the T hose to<br />

the branch of the tee on the T port.<br />

Step 10<br />

Connect the straight end of the P hose<br />

to the branch of the tee on the P port.<br />

Keep the connection loose at this stage.<br />

Step 11<br />

Connect the straight end of the LS hose<br />

to the 90° elbow on the LS port.<br />

AUTOPILOT AUTOMATED STEERING SYSTEM INSTALLATION INSTRUCTIONS<br />

42

2 – Hydraulic Control Valve <strong>Installation</strong><br />

Step 12<br />

Check that the P, T, and LS hoses are<br />

routed properly underneath the cab<br />

toward the <strong>Autopilot</strong> valve to minimize<br />

the risk of damage.<br />

Note – This tractor is fitted with a soft<br />

cab suspension that can cause large<br />

cab movements in rough terrain<br />

conditions. Therefore, attach the hoses<br />

to the chassis rather than the cab to<br />

prevent the hoses from being damaged.<br />

AUTOPILOT AUTOMATED STEERING SYSTEM INSTALLATION INSTRUCTIONS<br />

43

2 – Hydraulic Control Valve <strong>Installation</strong><br />

Connections for Type 2 machines<br />

Step 1<br />

At the rear of the machine locate the<br />

remote valve stack; this is where you<br />

will make the pressure, tank, and load<br />

sense connections.<br />

Step 2<br />

The LS connection point is on the back<br />

of the valve stack, between the cab and<br />

the valve stack, as shown.<br />

Step 3<br />

Locate and remove the plug in the LS<br />

connection port.<br />

AUTOPILOT AUTOMATED STEERING SYSTEM INSTALLATION INSTRUCTIONS<br />

44

2 – Hydraulic Control Valve <strong>Installation</strong><br />

Step 4<br />

Install the supplied fitting into the LS<br />

connection port.<br />

Mechanical remote valve stack LS port<br />

Step 5<br />

Insert an M12 ORB to -4 ORFS straight<br />

adaptor.<br />

Adaptor in LS port:<br />

Mechanical remote vave stack<br />

AUTOPILOT AUTOMATED STEERING SYSTEM INSTALLATION INSTRUCTIONS<br />

45

2 – Hydraulic Control Valve <strong>Installation</strong><br />

Step 6<br />

Attach the straight end of the LS hose<br />

to the fitting installed in Step 4 above,<br />

in the LS connection port.<br />

Adaptor in LS port:<br />

Electro-hydraulic valve stack<br />

Step 7<br />

The pressure and tank connection<br />

points are located in the area just<br />

below the valve stack, as shown.<br />

N<br />

V<br />

AUTOPILOT AUTOMATED STEERING SYSTEM INSTALLATION INSTRUCTIONS<br />

46

2 – Hydraulic Control Valve <strong>Installation</strong><br />

Step 8<br />

Remove the plugs in the P and T ports.<br />

Tapping on the plug with a mallet may<br />

help to loosen them.<br />

Step 9<br />

Assemble the supplied M27x2.0- 8ORS<br />

fitting into the tank port, as shown.<br />

AUTOPILOT AUTOMATED STEERING SYSTEM INSTALLATION INSTRUCTIONS<br />

47

2 – Hydraulic Control Valve <strong>Installation</strong><br />

Step 10<br />

Attach the straight end of the T hose to<br />

the branch of the run tee fitting.<br />

Step 11<br />

Remove the plug in the P port of the<br />

machine.<br />

Step 12<br />

Assemble the provided M22 fitting,<br />

then assemble the run tee fitting (with<br />

the cap on the end of the run tee<br />

fitting).<br />

AUTOPILOT AUTOMATED STEERING SYSTEM INSTALLATION INSTRUCTIONS<br />

48

2 – Hydraulic Control Valve <strong>Installation</strong><br />

Step 13<br />

Assemble the straight end of the P hose<br />

to the branch of the run tee fitting on<br />

the P port.<br />

Route all of the hoses under the cab to<br />

the <strong>Autopilot</strong> manifold.<br />

AUTOPILOT AUTOMATED STEERING SYSTEM INSTALLATION INSTRUCTIONS<br />

49

2 – Hydraulic Control Valve <strong>Installation</strong><br />

Connecting P, T and LS to the <strong>Autopilot</strong> manifold<br />

Step 1<br />

Assemble the 90° end of the P hose to<br />

the P port on the <strong>Autopilot</strong> manifold.<br />

Tighten both ends of the hose.<br />

Step 2<br />

Fit the T hose to the T port of the<br />

<strong>Autopilot</strong> manifold,<br />

Fit the LS hose to the LS2 port on the<br />

<strong>Autopilot</strong> manifold.<br />

The images to the right show the<br />

different hose orientations for the<br />

different manifold and DCBV mounting<br />

options.<br />

AUTOPILOT AUTOMATED STEERING SYSTEM INSTALLATION INSTRUCTIONS<br />

50

2 – Hydraulic Control Valve <strong>Installation</strong><br />

.<br />

AUTOPILOT AUTOMATED STEERING SYSTEM INSTALLATION INSTRUCTIONS<br />

51

CHAPTER<br />

3<br />

Autosense Steering Device<br />

<strong>Installation</strong> 3<br />

In this chapter:<br />

• Autosense steering device components<br />

• Installing the Autosense steering device<br />

• Preparing the harness (P/N 54602 Rev C)<br />

This chapter describes how to install the<br />

Autosense steering device.<br />

If the required mounting location is not<br />

accessible, chose a different place. To ensure<br />

proper function, the Autosense device must be<br />

located where it is free of obstructions and can<br />

rotate with the wheels when they turn.<br />

On articulated vehicles, mount the Autosense<br />

device on the opposite side of the pivot point to<br />

the <strong>Autopilot</strong> controller.<br />

Mount the device base down or base up so that<br />

it maintains a level orientation. Do not mount it<br />

on its side. An angle of up to 10° in any direction<br />

is acceptable.<br />

To avoid stretching the cable, leave adequate<br />

length on the service loop.<br />

AUTOPILOT AUTOMATED STEERING SYSTEM INSTALLATION INSTRUCTIONS 55

3 – Autosense Steering Device <strong>Installation</strong><br />

Autosense steering device components<br />

f<br />

g<br />

c<br />

e<br />

d<br />

Item Description Trimble part number<br />

c P-6 connector<br />

d<br />

e<br />

Power connector<br />

Autosense connector<br />

f Jumper cable 57560<br />

g Autosense steering cable 57885<br />

AUTOPILOT AUTOMATED STEERING SYSTEM INSTALLATION INSTRUCTIONS<br />

56

3 – Autosense Steering Device <strong>Installation</strong><br />

Installing the Autosense steering device<br />

C<br />

WARNING – To avoid potentially serious personal injury or illness, and to prevent damage to<br />

equipment, make sure that you read and understand the Safety Information chapter.<br />

Step 1<br />

Locate the mounting location at the left<br />

kingpin.<br />

Remove the two bolts shown.<br />

Step 2<br />

Use the existing hardware to mount the<br />

Autosense bracket as shown.<br />

Step 3<br />

Mount the Autosense device on the<br />

bracket with the connector pointing<br />

toward the center of the vehicle. Use<br />

the six provided #6 x ½" socket head<br />

screws.<br />

AUTOPILOT AUTOMATED STEERING SYSTEM INSTALLATION INSTRUCTIONS<br />

57

3 – Autosense Steering Device <strong>Installation</strong><br />

Step 4<br />

Turn the vehicle steering as far to the<br />

right as possible (the mechanical lock)<br />

to ensure that there is no risk of<br />

damage to the Autosense connector<br />

from the bolt that reduces the rotation<br />

of the fender.<br />

Step 5<br />

Standard axle<br />

If the tractor is fitted with a standard<br />

axle, route the steering cable to the<br />

steering device along the tie-rod and<br />

then connect it to the steering device.<br />

Supersteer axle<br />

If the tractor is fitted with a SuperSteer<br />

axle, route the steering cable along the<br />

main axle and then connect it to the<br />

steering device.<br />

STANDARD AXLE<br />

SUPERSTEER AXLE<br />

AUTOPILOT AUTOMATED STEERING SYSTEM INSTALLATION INSTRUCTIONS<br />

58

3 – Autosense Steering Device <strong>Installation</strong><br />

Step 6<br />

Secure the cable with cable ties or<br />

adhesive plastic consoles (not<br />

supplied).<br />

Leave adequate length on the service<br />

loop to avoid stretching the cable.<br />

CABLE TIES<br />

Step 7<br />

Connect the steering device cable<br />

connection to P-6 on the main wiring<br />

harness. P-6 is labeled “Steering<br />

Sensor”.<br />

ADHESIVE PLASTIC CONSOLES<br />

AUTOPILOT AUTOMATED STEERING SYSTEM INSTALLATION INSTRUCTIONS<br />

59

3 – Autosense Steering Device <strong>Installation</strong><br />

Preparing the harness (P/N 54602 Rev C)<br />

Step 1<br />

Remove the black Deutsch DTM<br />

receptacle from the P-13 sensors leg of<br />

the auxiliary harness. See Chapter 8,<br />

Controller <strong>Installation</strong>.<br />

Step 2<br />

Remove the plug from cavity number 1.<br />

Step 3<br />

Remove the wedge from the connector.<br />

AUTOPILOT AUTOMATED STEERING SYSTEM INSTALLATION INSTRUCTIONS<br />

60

3 – Autosense Steering Device <strong>Installation</strong><br />

Step 4<br />

Insert the DTM pin labeled “Cavity 1”<br />

into the connector.<br />

Step 5<br />

Pull back on the wire to seat the pin.<br />

Replace the wedge in the connector.<br />

AUTOPILOT AUTOMATED STEERING SYSTEM INSTALLATION INSTRUCTIONS<br />

61

CHAPTER<br />

4<br />

Antenna/External Receiver (If Used)<br />

<strong>Installation</strong> 4<br />

In this chapter:<br />

• Antenna and receiver installation options<br />

• Mounting an adjustable spar to roof bolts<br />

• AG-372 receiver with AgGPS 450/900 radio<br />

module (if equipped) components<br />

• Installing the AG-372 GPS receiver with<br />

AgGPS 450/900 radio module (if equipped)<br />

• Installing an AG-372 receiver with magnetic<br />

feet<br />

• AgGPS 542 receiver components<br />

• Installing the AgGPS 542 receiver<br />

This chapter describes how to install the<br />

required receiver and antenna, and radio<br />

module (if used).<br />

To install the antenna for the CFX-750 or FmX<br />

display, see Chapter 5, Display <strong>Installation</strong>.<br />

AUTOPILOT AUTOMATED STEERING SYSTEM INSTALLATION INSTRUCTIONS 62

4 – Antenna/External Receiver (If Used) <strong>Installation</strong><br />

Antenna and receiver installation options<br />

There are several options for mounting components (the antenna, radio module, or GNSS receiver)<br />

on the cab roof depending on the accuracy required and the antenna type:<br />

• Spar mount – This bracket mounts directly to the roof bolts and is required for all high accuracy<br />

applications such as RTK and OmniSTAR. Trimble recommends this method for mounting an<br />

AG-372 receiver. Bolt a metal spar to the roof or to a light bracket and then attach either a V plate<br />

for magnetic mounting or an AG-372 receiver plate for permanent mounting.<br />

• VHB mount – Attach a 4" x 6" plate or a V plate directly to the roof with VHB (Very High Bond)<br />

adhesive for magnetic mounting. See page 66.<br />

• Magnetic mounting – Magnetic mounting for quick release is available for both VHB and spar<br />

type mounting.<br />

Possible mounting methods<br />

GNSS receiver VHB mounted plate VHB V mounted plate AG15/AG25/Zephyr/<br />

AG-372 bolted to spar<br />

mount<br />

CFX-750 display;<br />

FmX integrated display<br />

<br />

AG-372 receiver <br />

AgGPS 542 receiver <br />

Notes:<br />

– For quick release magnetic mounting with an AG-372 receiver, order the kit listed in Antenna<br />

mounting kits, page 8 and bolt the V plate to the spar.<br />

– With all other antennas, bolt the V plate to the spar for high accuracy and repeatability.<br />

– For WAAS, EGNOS, OmniSTAR VBS, Beacon, and DGPS applications, place either of the plates in a<br />

firm location using the VHB.<br />

AUTOPILOT AUTOMATED STEERING SYSTEM INSTALLATION INSTRUCTIONS<br />

63

4 – Antenna/External Receiver (If Used) <strong>Installation</strong><br />

Mounting an adjustable spar to roof bolts<br />

C<br />

WARNING – To avoid potentially serious personal injury or illness, and to prevent damage to<br />

equipment, make sure that you read and understand the Safety Information.<br />

Step 1<br />

Locate the cab bolts on the roof of the<br />

vehicle.<br />

Measure the length between the bolts<br />

on the roof of the vehicle and order the<br />

appropriate spar:<br />

• Spar 36.5" - 46.5": P/N 53676<br />

• Spar 54" - 64": P/N 66774<br />

If a light bracket already occupies the<br />

roof studs, mount the spar directly onto<br />

the light bracket.<br />

Step 2<br />

If required, replace the existing bolts<br />

with longer bolts.<br />

AUTOPILOT AUTOMATED STEERING SYSTEM INSTALLATION INSTRUCTIONS<br />

64

4 – Antenna/External Receiver (If Used) <strong>Installation</strong><br />

If you use the light bracket, drill two<br />

holes to match the spar width.<br />

Step 3<br />

Use the slotted holes to center the spar<br />

and then tighten the bolts. If required,<br />

use the spacers and flat washers<br />

provided to secure the spar.<br />

Note – If the receiver is offset to the left<br />

or the right of the vehicle, <strong>Autopilot</strong><br />

system performance may be affected.<br />

Before you tighten the cab bolts, make<br />

sure that the GNSS antenna is aligned<br />

with the center of the vehicle.<br />

Step 4<br />

For either of the following applications:<br />

• A single magnet antenna mount<br />

• An AG-372 receiver with magnetic<br />

option for quick removal<br />

Attach a V plate with four ¼" flathead<br />

screws.<br />

The narrow end points to the front of<br />

the vehicle.<br />

V plate on the spar<br />

AUTOPILOT AUTOMATED STEERING SYSTEM INSTALLATION INSTRUCTIONS<br />

65

4 – Antenna/External Receiver (If Used) <strong>Installation</strong><br />

Magnetic mount on the V plate<br />

If you use a standard AG-372 plate for<br />

permanent mounting, install the radio<br />

antenna first. Use four ¼" flathead<br />

screws to attach the plate, with the<br />

handle toward the back of the vehicle.<br />

Front of vehicle<br />

Plate on the spar<br />

AUTOPILOT AUTOMATED STEERING SYSTEM INSTALLATION INSTRUCTIONS<br />

66

4 – Antenna/External Receiver (If Used) <strong>Installation</strong><br />

Attaching the plate with VHB adhesive<br />

C<br />

WARNING – To avoid potentially serious personal injury or illness, and to prevent damage to<br />

equipment, make sure that you read and understand the Safety Information.<br />

Standard 4" x 6" plates are provided in most kits. You can use the VHB mounting method to attach<br />

either a 4" x 6" plate or a V plate.<br />

• RTK, OmniSTAR, DGPS, GLONASS applications – To use this method for high accuracy, the surface<br />

must be rigid and free of “oil panning”. For RTK or OmniSTAR HP corrections, the spar method is<br />

recommended. The V plate provides repeatable positioning of the antenna.<br />

• WAAS, EGNOS, OmniSTAR VBS, Beacon applications – Use a 4" x 6" plate for simplified<br />

installation in applications where high accuracy is not critical.<br />

Step 1<br />

Clean the antenna location on the roof<br />

of the cab with a light solvent to<br />

remove oil and dust. Apply force to the<br />

roof to find a firm location.<br />

Step 2<br />

V plate only<br />

Remove the backing from one side of<br />

the VHB strips provided and then apply<br />

the strips to the plate.<br />

Note – The VHB strips are pre-applied<br />

to the 4" x 6" plate.<br />

AUTOPILOT AUTOMATED STEERING SYSTEM INSTALLATION INSTRUCTIONS<br />

67

4 – Antenna/External Receiver (If Used) <strong>Installation</strong><br />

Step 3<br />

Remove the backing from the other<br />

side of the VHB strips and then apply<br />

the plate to the cab roof. The narrow<br />

end of the plate points forward. Ensure<br />

that the VHB strips make even contact<br />

with the surface. Apply pressure and<br />

then leave for approximately 30<br />

minutes to adhere.<br />

Note – The arrow points to the front of<br />

the vehicle.<br />

V plate<br />

4" x 6" plate<br />

AUTOPILOT AUTOMATED STEERING SYSTEM INSTALLATION INSTRUCTIONS<br />

68

4 – Antenna/External Receiver (If Used) <strong>Installation</strong><br />

AG-372 receiver with AgGPS 450/900 radio module (if<br />

equipped) components<br />

❺<br />

❹<br />

❶<br />

❸<br />

❷<br />

Item Description Trimble part number<br />

❶ AgGPS 450 or 900 radio (if equipped)<br />

❷ Radio antenna cable and magnetic mount<br />

❸ AgGPS 450 or 900 radio antenna<br />

❹ Antenna/receiver cable 54608<br />

❺ <strong>Autopilot</strong> controller<br />

AUTOPILOT AUTOMATED STEERING SYSTEM INSTALLATION INSTRUCTIONS<br />

69

4 – Antenna/External Receiver (If Used) <strong>Installation</strong><br />

Installing the AG-372 GPS receiver with<br />

AgGPS 450/900 radio module (if equipped)<br />

C<br />

WARNING – To avoid potentially serious personal injury or illness, and to prevent damage to<br />

equipment, make sure that you read and understand the Safety Information.<br />

To attach the AG-372 receiver plate to the cab roof, do one of the following:<br />

• For a removable installation, attach a V plate to a spar and then stick the receiver plate to the V<br />

plate with magnets.<br />

• For a permanent installation, bolt the receiver plate to a spar.<br />

Removable installation<br />

Step 1<br />

V plate<br />

Attach the V plate to the spar using the<br />

¼" flathead screws provided in the V<br />

plate bolt kit. Ensure that the narrow<br />

end points forward.<br />

For spar mounting instructions, see<br />

page 64.<br />

Mounting plate<br />

Attach the three provided magnets to<br />

the plate with the ¼" flathead screws<br />

and hardware provided.<br />

Underside of plate<br />

AUTOPILOT AUTOMATED STEERING SYSTEM INSTALLATION INSTRUCTIONS<br />

70

4 – Antenna/External Receiver (If Used) <strong>Installation</strong><br />

Permanent installation<br />

Step 1<br />

Use the four provided ¼" flathead screws ❶<br />

to attach the receiver mounting bracket to the<br />

spar.<br />

For spar mounting instructions, see page 64.<br />

❶<br />

Step 2<br />

Remove the blanking plate and set it<br />

aside.<br />

Step 3<br />

Place the integrated radio inside the<br />

AG-372 receiver. Ensure that the circuit<br />

board is aligned with the slot in the<br />

vertical wall of the receiver.<br />

AUTOPILOT AUTOMATED STEERING SYSTEM INSTALLATION INSTRUCTIONS<br />

71

4 – Antenna/External Receiver (If Used) <strong>Installation</strong><br />

Step 4<br />

Slide the integrated radio back so that it<br />

is flush with the vertical wall of the<br />

receiver.<br />

Step 5<br />

Use a #1 or #2 Phillips screwdriver and<br />

the supplied screws to install the<br />

integrated radio. First insert and tighten<br />

the two screws on the horizontal wall<br />

(arrowed), and then insert the<br />

remaining screws.<br />

Step 6<br />

Install the supplied antenna cable.<br />

Note – The housing can accommodate<br />

a cable diameter of up to ¼".<br />

AUTOPILOT AUTOMATED STEERING SYSTEM INSTALLATION INSTRUCTIONS<br />

72

4 – Antenna/External Receiver (If Used) <strong>Installation</strong><br />

Step 7<br />

Route the cable through the cable<br />

channel and then insert the cable cover.<br />

This image shows the unit with the<br />

cable routed through the channel.<br />

Step 8<br />

Attach the antenna base to the rear of<br />

the plate with the two flathead screws<br />

provided.<br />

AUTOPILOT AUTOMATED STEERING SYSTEM INSTALLATION INSTRUCTIONS<br />

73

4 – Antenna/External Receiver (If Used) <strong>Installation</strong><br />

Step 9<br />

Attach the radio antenna to the<br />

antenna base.<br />

Step 10<br />

Position the AG-372 receiver and radio<br />

on the mounting plate with the<br />

connector ports facing the radio<br />

antenna. Align the three bolt holes with<br />

the receiver, radio, and mounting plate.<br />

Step 11<br />

Insert the nylon bushings provided.<br />

AUTOPILOT AUTOMATED STEERING SYSTEM INSTALLATION INSTRUCTIONS<br />

74

4 – Antenna/External Receiver (If Used) <strong>Installation</strong><br />

Step 12<br />

Insert the bolts through the receiver,<br />

radio, and mounting bracket. Place nuts<br />

on the bolt ends and then tighten<br />

them.<br />

Step 13<br />

Magnet method<br />

Place the receiver on the roof by<br />

aligning the magnets with the V plate.<br />

Ensure that the handle ❶ is toward<br />

the back of the vehicle.<br />

❶<br />

Step 14<br />

Both methods<br />

Connect the cable from the cab<br />

controller into port A ❶ of the AG-372<br />

receiver. Bolt the cable clamp ❷ to the<br />

left side of the receiver.<br />

Route the cable into the cab and into<br />

the controller.<br />

❷<br />

❶<br />

AUTOPILOT AUTOMATED STEERING SYSTEM INSTALLATION INSTRUCTIONS<br />

75

4 – Antenna/External Receiver (If Used) <strong>Installation</strong><br />