- Page 2:

Metric & American INDUSTRIAL POWER

- Page 5 and 6:

General Overview Stock Bearing Prod

- Page 7 and 8:

Specialty Products Linear Bearings

- Page 9 and 10:

Mounted Ball Bearings Product Overv

- Page 11 and 12:

Ball Bearing Selection Criteria Loa

- Page 13 and 14:

Mounted Ball Bearing Interchange No

- Page 15 and 16:

Mounted Ball Bearing Interchange No

- Page 17 and 18:

Pillow Block UCP 200 Gold Series No

- Page 19 and 20:

Pillow Block RAK 200 Gold Series No

- Page 21 and 22:

Pillow Block VAK 200 Gold Series No

- Page 23 and 24:

Pillow Block SW 200 Gold Series Nor

- Page 25 and 26:

Pillow Block UKP 200 Silver Series

- Page 27 and 28:

Pillow Block CLRAK 200 Silver Serie

- Page 29 and 30:

Pillow Block RAKH 200 Gold Series N

- Page 31 and 32:

Pillow Block RAKHL 200 Gold Series

- Page 33 and 34:

Medium Duty Pillow Block PX and PXL

- Page 35 and 36:

Pressed Steel Pillow Block BS 200 G

- Page 37 and 38:

Light Duty Pillow Block UP 000 Silv

- Page 39 and 40:

Tapped Base Pillow Block TB 200 Gol

- Page 41 and 42:

Tapped Base Pillow Block PA 200 Gol

- Page 43 and 44:

Tapped Base Pillow Block SWG 200 Go

- Page 45 and 46:

Tapped Base Pillow Block GSHTB 200

- Page 47 and 48:

4-Bolt Flange UCF 200 Gold Series N

- Page 49 and 50:

4-Bolt Flange FWS 200 Gold Series N

- Page 51 and 52:

4-Bolt Flange GSHF 200 Silver Serie

- Page 53 and 54:

Medium Duty 4-Bolt Flange UCFX Silv

- Page 55 and 56:

Piloted 4-Bolt Flange UCFC 200 Gold

- Page 57 and 58:

Piloted 4-Bolt Flange FCF 200 Gold

- Page 59 and 60:

Piloted 4-Bolt Flange GSHFC 200 Sil

- Page 61 and 62:

Piloted 4-Bolt Flange CLFC 200 Silv

- Page 63 and 64:

Piloted 4-Bolt Flange FWSN 200 Gold

- Page 65 and 66:

Piloted 4-Bolt Flange RVFW 200 Gold

- Page 67 and 68:

3-Bolt Flanged Bracket FB 200 Gold

- Page 69 and 70:

3-Bolt Flanged Bracket GSHFB 200 Si

- Page 71 and 72:

Ductile 3-Bolt Flange F3X 200 Gold

- Page 73 and 74:

3-Bolt Flange DFW 200 Gold Series N

- Page 75 and 76:

Pressed Steel Flange Units BF Gold

- Page 77 and 78:

Pressed Steel 3-Bolt Flange DBF 200

- Page 79 and 80:

2-Bolt Flange UCFL 200 Gold Series

- Page 81 and 82:

2-Bolt Flange UCFT 200 Gold Series

- Page 83 and 84:

2-Bolt Flange OWF 200 Gold Series N

- Page 85 and 86:

2 Bolt Piloted Flange OWFZ 200 Gold

- Page 87 and 88:

2-Bolt Flange OWFS 200 Gold Series

- Page 89 and 90:

2-Bolt Flange HCFJT 200 Silver Seri

- Page 91 and 92:

2-Bolt Flange GSHFT 200 Silver Seri

- Page 93 and 94:

2-Bolt Flange UKFL 200 Silver Serie

- Page 95 and 96:

2-Bolt Flange CLFL 200 Silver Serie

- Page 97 and 98:

Medium Duty 2-Bolt Flange FLX Silve

- Page 99 and 100:

2-Bolt Flange OWFK 200 Gold Series

- Page 101 and 102:

2-Bolt Flange LF 200 Gold Series No

- Page 103 and 104:

Ductile 2-Bolt Flange FX 200 Gold S

- Page 105 and 106:

Pressed Steel Flange OBF 200 Gold S

- Page 107 and 108:

Pressed Steel Flange with Rubber Is

- Page 109 and 110:

Swivel Flange WSFL 200 Gold Series

- Page 111 and 112:

Take-Up UCT 200 Gold Series Normal

- Page 113 and 114:

Take-Up HCT 200 Gold Series Normal

- Page 115 and 116:

Take-Up GSHT 200 Silver Series Thin

- Page 117 and 118:

Wide Slot Take-Up WS 200 Gold Serie

- Page 119 and 120:

Wide Slot Take-Up CLWS 200 Silver S

- Page 121 and 122:

Take-Up SPK 200 Gold Series Normal

- Page 123 and 124:

Hanger Bearing HA 200 Gold Series N

- Page 125 and 126:

Cylindrical Units HLW 200 Gold Seri

- Page 127 and 128:

Ball Bearing Inserts UC 200 Gold Se

- Page 129 and 130:

Ball Bearing Inserts SB 200 Gold Se

- Page 131 and 132:

Ball Bearing Inserts HC 200 Gold Se

- Page 133 and 134:

Ball Bearing Inserts SA 200 Gold Se

- Page 135 and 136:

Medium Duty Ball Bearing Inserts UC

- Page 137 and 138:

Ball Bearing Inserts and Accessorie

- Page 139 and 140:

Ball Bearing Inserts CL 200 Silver

- Page 141 and 142:

Ball Bearing Inserts U000 Silver Se

- Page 143 and 144:

Stainless, Thermoplastic & Nickel P

- Page 145 and 146:

Stainless Steel Pillow Block SUCSP

- Page 147 and 148:

Thermoplastic Pillow Block SUCTP 20

- Page 149 and 150:

Stainless Steel Tapped Base SUCSPA

- Page 151 and 152:

Thermoplastic Tapped Base SUCTTB 20

- Page 153 and 154:

Stainless Steel 4-Bolt Flange SUCSF

- Page 155 and 156:

Thermoplastic 4-Bolt Flange Units S

- Page 157 and 158:

Stainless Steel Piloted 4-Bolt Flan

- Page 159 and 160:

Stainless Steel 2-Bolt Flange SUCSF

- Page 161 and 162:

Thermoplastic 2-Bolt Flange SUCTFL

- Page 163 and 164:

Stainless Steel 3-Bolt Flanged Brac

- Page 165 and 166:

Thermoplastic 3-Bolt Flange Bracket

- Page 167 and 168:

Stainless Steel Take-Up SUCST 200 S

- Page 169 and 170:

Thermoplastic Take-Up Units SUCTT 2

- Page 171 and 172:

PBT Covers for Thermoplastic Housin

- Page 173 and 174:

Stainless Steel Ball Bearing Insert

- Page 175 and 176:

Stainless Steel Ball Bearing Insert

- Page 177 and 178:

More Split Pillow Blocks & Special

- Page 179 and 180:

Pillow Block Housings SAF 500 Serie

- Page 181 and 182:

Pillow Block Housings SAF 600 Serie

- Page 183 and 184:

SAF Split Block Accessories Tac Sea

- Page 185 and 186:

Pillow Block Housings SAF 200 Serie

- Page 187 and 188:

Pillow Block Housings SAF 300 Serie

- Page 189 and 190:

Pillow Block Housings SDAF 500 Seri

- Page 191 and 192:

Pillow Block Housings SDAF 200 Seri

- Page 193 and 194:

Pillow Block Housings SAF 000 Serie

- Page 195 and 196:

Pillow Block Housings SDAF 230 Seri

- Page 197 and 198:

Pillow Block Housings SDAF 231 Seri

- Page 199 and 200:

Pillow Block Housings SDAF 232 Seri

- Page 201 and 202:

Plummer Block Housings SNG 500 Seri

- Page 203 and 204:

Metric Plummer Block SNG 500-600 Se

- Page 205 and 206:

Plummer Block Housings SNG 600 Seri

- Page 207 and 208: Plummer Block Housings SN 500 Serie

- Page 209 and 210: Plummer Block Housings SN 600 Serie

- Page 211 and 212: Plummer Block Housings SN 200 Serie

- Page 213 and 214: Plummer Block Housings SN 300 Serie

- Page 215 and 216: Bronze Journal Bearings DIN 505 Ser

- Page 217 and 218: Plummer Block Housings SD 3100 TS S

- Page 219 and 220: Flanged Housings 722500 Series - 3

- Page 221 and 222: HSPA Take-Up Units HSPA Take-Up Uni

- Page 223 and 224: Plummer Block Housings HFO 200 Seri

- Page 225 and 226: Double Bearing Housings PDNF Series

- Page 227 and 228: Self-Aligning Ball Bearings 2200 &

- Page 229 and 230: Spherical Roller Bearings 223 Serie

- Page 231 and 232: Spherical Roller Bearings 231 Serie

- Page 233 and 234: Adapter Interchange H-Type SNW Type

- Page 235 and 236: Adapter Sleeves SNW 00 Series Inch

- Page 237 and 238: Adapter Sleeves SNP 3000 Series Inc

- Page 239 and 240: Adapter Sleeves H300 Series (for 22

- Page 241 and 242: Adapter Sleeves H3200 Series Metric

- Page 243 and 244: Hydraulic Adapter Sleeves OH3200 Se

- Page 245 and 246: Metric Lock Nuts KM Series KML Seri

- Page 247 and 248: Inch Lock Nuts N00 Series AN00 Seri

- Page 249 and 250: GUK Type Lock Nuts Self-Locking nut

- Page 251 and 252: Inch Lock Washers W00 Series W000 S

- Page 253 and 254: Withdrawal Sleeves Metric Bores d T

- Page 255 and 256: Roller Bearings Eich Roller Bearing

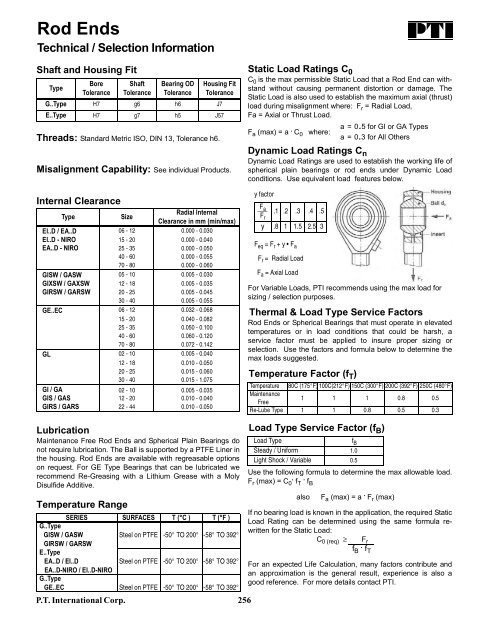

- Page 257: Metric Rod Ends Rod ends are availa

- Page 261 and 262: Metric Rod Ends GIS Type Heavy Duty

- Page 263 and 264: Metric Rod Ends GIRS Type Stainless

- Page 265 and 266: Metric Rod Ends GIXSW Type Heat Tre

- Page 267 and 268: Metric Rod Ends EI Type Steel on St

- Page 269 and 270: Metric Rod Ends EI..D SS Type Stain

- Page 271 and 272: Metric Hydraulic Rod Ends FPR..U Ty

- Page 273 and 274: Metric Rod Ends Inquiry Template Fa

- Page 275 and 276: Winkel Combined Bearings and Profil

- Page 277 and 278: Linear Systems The Economical Solut

- Page 279 and 280: Fixed Axial Bearing Combined Bearin

- Page 281 and 282: Combined Bearings Adjustable Eccent

- Page 283 and 284: Combined Bearings Shim Adjustable A

- Page 285 and 286: Heavy Duty Combined Bearings Type 3

- Page 287 and 288: Axial Bearing Adjustable Jumbo Comb

- Page 289 and 290: Combined Bearings Type JC Adjusting

- Page 291 and 292: Single Profiles Standard Series All

- Page 293 and 294: Single Profiles Precision Series Al

- Page 295 and 296: Duplex Profiles Standard Series Mat

- Page 297 and 298: Vulkollan Combined Bearings Part No

- Page 299 and 300: Vulkollan Combined Bearings Part No

- Page 301 and 302: Profiles for Vulkollan & Polyamide

- Page 303 and 304: Polyamide Combined Bearings Part No

- Page 305 and 306: Chain Selection Criteria Guide Line

- Page 307 and 308: Metric (British Standard) Roller Ch

- Page 309 and 310:

Metric Attachment Chain E-Series -

- Page 311 and 312:

Metric Attachment Chain E-Series -

- Page 313 and 314:

Stainless Steel Roller Chain E-Seri

- Page 315 and 316:

Attachment Chain Worksheet Overview

- Page 317 and 318:

Metric Roller Chain with Straight S

- Page 319 and 320:

Lube Free Roller Chain Marathon Ser

- Page 321 and 322:

Lube Free - Stainless Roller Chain

- Page 323 and 324:

Accumulator Chain For Automated Con

- Page 325 and 326:

Agricultural & Lumber Roller Chain

- Page 327 and 328:

Metric Conveyor Chain Solid Bearing

- Page 329 and 330:

Metric Conveyor Chain Deep Link Sol

- Page 331 and 332:

Metric Conveyor Chain Deep Link Hol

- Page 333 and 334:

Metric Sprockets ISO 03B Hub Type B

- Page 335 and 336:

Metric Sprockets ISO 04B & 05B Hub

- Page 337 and 338:

Metric Sprockets bf 1 ISO 05B Plate

- Page 339 and 340:

Metric Sprockets Standard, Hardened

- Page 341 and 342:

Metric Sprockets ISO 06B Plate Type

- Page 343 and 344:

Metric Sprockets bf 1 ISO 081B Plat

- Page 345 and 346:

Metric Sprockets ISO 085B Hub Type

- Page 347 and 348:

Metric Sprockets Taper Bushed Type

- Page 349 and 350:

Metric Sprockets ISO 08B-2 and 08B-

- Page 351 and 352:

Metric Sprockets Taper Bushed Type

- Page 353 and 354:

Metric Sprockets ISO 10B-2 and 10B-

- Page 355 and 356:

Metric Sprockets Taper Lock Bushed

- Page 357 and 358:

Metric Sprockets ISO 12B-2 and 12B-

- Page 359 and 360:

Metric Sprockets Taper Bushed Type

- Page 361 and 362:

Metric Sprockets ISO 16B-2 and 16B-

- Page 363 and 364:

Metric Sprockets Taper Bushed Type

- Page 365 and 366:

Metric Sprockets ISO 20B-2, 20B-3 H

- Page 367 and 368:

Metric Sprockets ISO 24B Hub Type B

- Page 369 and 370:

Metric Sprockets ISO 32B Hub Type B

- Page 371 and 372:

Metric Idler Sprockets Part No. Cha

- Page 373 and 374:

Taper Bushings & Keystock - Metric

- Page 376 and 377:

Spur Gear and Gear Rack Basics Ther

- Page 378 and 379:

Metric Gear Racks for Spur Gears Fe

- Page 380 and 381:

Metric Spur Gear with Hub Module 1.

- Page 382 and 383:

Metric Spur Gear with Hub Module 2.

- Page 384 and 385:

Metric Spur Gear with Hub Module 4

- Page 386 and 387:

Metric Spur Gear with Hub Module 6

- Page 388 and 389:

Synchronous Pulleys - Pilot Bore, B

- Page 390 and 391:

Synchronous Pulleys - Taper Bushed

- Page 392 and 393:

Synchronous Pulleys - Taper Bushed

- Page 394 and 395:

Metric Timing Pulleys T Series - 2.

- Page 396 and 397:

Metric Timing Pulleys T Series - 5

- Page 398 and 399:

Metric Timing Pulleys T Series - 10

- Page 400 and 401:

Metric Timing Pulleys AT Series - 5

- Page 402 and 403:

Metric Timing Pulleys AT Series - 1

- Page 404 and 405:

8M HTD ® Pulleys - Taper Bushed 8

- Page 406 and 407:

8M HTD ® Pulleys - Taper Bushed 8

- Page 408 and 409:

14M HTD ® Pulleys - Taper Bushed 1

- Page 410 and 411:

Super Torque Timing Pulley Taper Bu

- Page 412 and 413:

Super Torque Timing Pulley Taper Bu

- Page 414 and 415:

Metric V-Belt TL Taper Bushed Sheav

- Page 416 and 417:

SPZ Metric V-Belt Sheaves - Taper B

- Page 418 and 419:

SPZ Metric V-Belt Sheaves - Taper B

- Page 420 and 421:

SPA Metric V-Belt Sheaves - Taper B

- Page 422 and 423:

SPA Metric V-Belt Sheaves - Taper B

- Page 424 and 425:

SPB Metric V-Belt Sheaves - Taper B

- Page 426 and 427:

SPB Metric V-Belt Sheaves - Taper B

- Page 428 and 429:

SPB Metric V-Belt Sheaves - Taper B

- Page 430 and 431:

SPC Metric V-Belt Sheaves - Taper B

- Page 432 and 433:

SPC Metric V-Belt Sheaves - Taper B

- Page 434 and 435:

Metric Variable Pitch Pulley Adjust

- Page 436 and 437:

Flexible Shaft Couplings HRC Series