Stepper drives Servostep drives Controllers

Stepper drives Servostep drives Controllers

Stepper drives Servostep drives Controllers

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

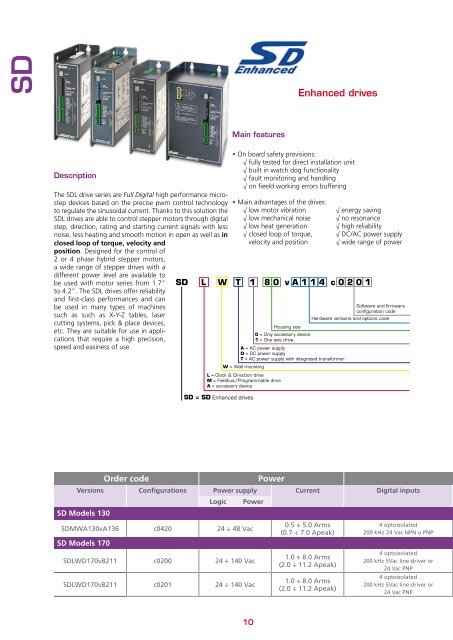

SD<br />

Enhanced <strong>drives</strong><br />

0 8 1 - 0 0<br />

Main features<br />

SW1 A 9 1 6 0 C 0 6 1 - 0 0 c 0 3 0 0<br />

• On board safety provisions:<br />

√ fully tested for direct installation unit<br />

√ built in watch dog functionality<br />

Axles number Description<br />

I/O configuration code<br />

√ fault monitoring and handling<br />

Hardware versions and options code<br />

Axles number<br />

√ on fieeld working errors buffering<br />

0 = No serial interface<br />

I/O configuration code<br />

The SDL drive series are Full Digital high performance microstep<br />

devices based on the precise pwm control technology • Main advantages of the <strong>drives</strong>:<br />

0 = No serial interface · 3 = RS232/ RS422<br />

N = No fieldbus<br />

to regulate the sinusoidal current. Thanks to this solution the √ low motor vibration<br />

· C = CANbus · P = Profibus<br />

√ energy saving<br />

Max current in Amps *10<br />

SDL <strong>drives</strong> are able to control stepper motors through digital √ low mechanical noise √ no resonance<br />

0 = Single power supply<br />

step, direction, rating and starting current signals with less 1 = Separated √ low heat power generation<br />

supply inputs for logic and √ power high reliability<br />

noise, less heating and smooth motion in open as well as Voltage in range √ closed code loop of torque, √ DC/AC power supply<br />

closed loop of torque, velocity and<br />

A = AC power supply velocity · D = DC and power position supply<br />

√ wide range of power<br />

position. Designed for the control of<br />

2 or 4 phase hybrid stepper motors,<br />

SW1= Wall mounting software controlled <strong>drives</strong><br />

a wide range of stepper <strong>drives</strong> with a<br />

different power level are available to<br />

v 4 2 2 1 c be 0 used 3 x with x motor series from 1.7” SD L W T 1 8 0 v A 1 1 4 c 0 2 0 1<br />

to 4.2”. The SDL <strong>drives</strong> offer reliability<br />

and first-class performances and can<br />

o fieldbus<br />

mps *10<br />

er supply<br />

rolled <strong>drives</strong><br />

using size<br />

cessory device<br />

s drive<br />

Options code<br />

Hardware versions and options code<br />

ply<br />

ply<br />

ly with integrated transformer<br />

be used Software in many and firmware types of machines<br />

configuration code<br />

such as such as X-Y-Z tables, laser<br />

cutting systems, pick & place devices,<br />

etc. They are suitable for use in applications<br />

that require a high precision,<br />

speed and easiness of use.<br />

Housing size<br />

0 = Only accessory device<br />

1 = One axis drive<br />

A = AC power supply<br />

D = DC power supply<br />

T = AC power supply with integrated transformer<br />

W = Wall mounting<br />

L = Clock & Direction drive<br />

M = Fieldbus/Programmable drive<br />

A = accessory device<br />

Software and firmware<br />

configuration code<br />

Software and firmware<br />

configuration code<br />

Hardware versions and options code<br />

SW<br />

S<br />

SD = SD Enhanced <strong>drives</strong><br />

4 3 B 4 0 c 0 3 0 0<br />

SM 2 A 6 60P N 3 4 3 C 4 0 c 0 4 9 9<br />

GW<br />

Order code<br />

Software and firmware<br />

configuration code<br />

0 = options number<br />

N = No encoder<br />

4 = 400 ppr integrated incremental encoder<br />

A = 3.4 Nm 1/2 stack motor<br />

B = 4.5 Nm 1 SD stack Models motor 130<br />

C = 7.0 Nm 2 stacks motor<br />

D = 8.5 Nm 3 stacks motor<br />

E = 12.5 Nm 4 stacks motor<br />

Power<br />

Versions Configurations Power supply Current Digital inputs<br />

Logic<br />

SDMWA130vA136 c0420 24 ÷ 48 Vac<br />

3 = motor flange dimension (3,4" - 86 mm)<br />

SD Models 170<br />

4 = 4 digital inputs and 2 digital outputs<br />

Power<br />

A = motore 1/2 stadio da 3,4 Nm<br />

B = motore 1 stadio da 4,5 Nm<br />

C = motore 2 stadi da 7,0 Nm<br />

0.5 ÷ 5.0<br />

D =<br />

Arms<br />

motore 3 stadi da 8,5 Nm 4 optoisolated<br />

E = motore 4 stadi da 12,5 Nm<br />

(0.7 ÷ 7.0 Apeak)<br />

200 kHz 24 Vac NPN o PNP<br />

3 = flangia motore da 3,4” (86 mm)<br />

= CANbus interface with in and out connection<br />

C0 = interfaccia CAN Bus con connessione in/out 4 optoisolated<br />

= Profibus interface<br />

N3 = 1.0 interfaccia ÷ 8.0 RS232 Arms/ RS485<br />

SDLWD170vB211 c0200 24 ÷ 140 Vac<br />

200 kHz 5Vac line-driver or<br />

3 = RS232 / RS485 interface<br />

N2 (2.0 = interfaccia ÷ 11.2 RS485 Apeak) con connessione in/out<br />

2 = RS485 interface with in and out connection<br />

24 Vac PNP<br />

60P = Motore da 6.0 Amps connesso in bipolare parallelo<br />

ps motor in bipolar parallel connection<br />

4 optoisolated<br />

5 = Ingresso di alimentazione 1.0 ÷ separato 8.0 Arms per logica e potenza<br />

supply inputs for logic and power SDLWD170vB211 c0201 24 ÷ 140 6 = Ingresso Vac unico per alimentazione<br />

200 kHz 5Vac line-driver or<br />

ly input<br />

(2.0 ÷ 11.2 Apeak)<br />

A = Alimentazione in AC monofase/trifase<br />

24 Vac PNP<br />

or three phases<br />

D = Alimentazione in DC<br />

2 = Codice interno<br />

Codice firmware<br />

e configurazione software<br />

0 = Numero opzioni<br />

N = nessun encoder<br />

4 = encoder incrementale integrato da 400 ppr<br />

4 = 4 ingressi digitali e 2 uscite digitali<br />

SM = Smart Motor<br />

10