Threading Solutions - Vargus

Threading Solutions - Vargus

Threading Solutions - Vargus

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

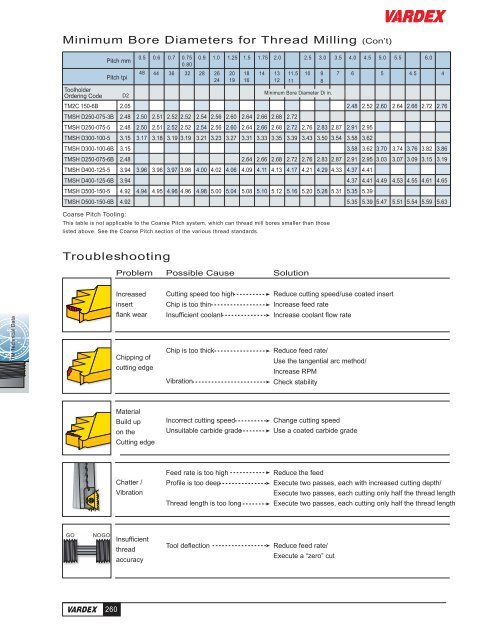

Minimum Bore Diameters for Thread Milling (Con’t)<br />

Toolholder<br />

Ordering Code<br />

Pitch mm<br />

Pitch tpi<br />

D2<br />

0.5<br />

48<br />

0.6 0.7 0.75<br />

0.80<br />

44 36 32<br />

0.9<br />

1.0<br />

28 26<br />

24<br />

1.25<br />

20<br />

19<br />

1.5<br />

18<br />

16<br />

1.75<br />

14<br />

2.0<br />

13<br />

12<br />

11.5<br />

11<br />

2.5<br />

10<br />

3.0<br />

9<br />

8<br />

Minimum Bore Diameter Di in.<br />

3.5<br />

7<br />

4.0<br />

6<br />

4.5<br />

5.0 5.5 6.0<br />

5<br />

4.5<br />

4<br />

TM2C 150-6B<br />

2.05<br />

2.48<br />

2.52<br />

2.60<br />

2.64<br />

2.66<br />

2.72<br />

2.76<br />

TMSH D250-075-3B<br />

2.48<br />

2.50<br />

2.51<br />

2.52 2.52<br />

2.54<br />

2.56<br />

2.60<br />

2.64<br />

2.66<br />

2.68<br />

2.72<br />

TMSH D250-075-5<br />

2.48<br />

2.50<br />

2.51<br />

2.52 2.52<br />

2.54<br />

2.56<br />

2.60<br />

2.64<br />

2.66<br />

2.68<br />

2.72<br />

2.76<br />

2.83<br />

2.87<br />

2.91<br />

2.95<br />

TMSH D300-100-5<br />

3.15<br />

3.17<br />

3.18<br />

3.19 3.19<br />

3.21<br />

3.23<br />

3.27<br />

3.31<br />

3.33<br />

3.35<br />

3.39<br />

3.43<br />

3.50<br />

3.54<br />

3.58<br />

3.62<br />

TMSH D300-100-6B<br />

3.15<br />

3.58<br />

3.62<br />

3.70<br />

3.74<br />

3.76<br />

3.82<br />

3.86<br />

TMSH D250-075-6B<br />

2.48<br />

2.64<br />

2.66<br />

2.68<br />

2.72<br />

2.76<br />

2.83<br />

2.87<br />

2.91<br />

2.95<br />

3.03<br />

3.07<br />

3.09<br />

3.15<br />

3.19<br />

TMSH D400-125-5<br />

3.94<br />

3.96<br />

3.96<br />

3.97 3.98<br />

4.00<br />

4.02<br />

4.06<br />

4.09<br />

4.11<br />

4.13<br />

4.17<br />

4.21<br />

4.29<br />

4.33<br />

4.37<br />

4.41<br />

TMSH D400-125-6B<br />

3.94<br />

4.37<br />

4.41<br />

4.49<br />

4.53<br />

4.55<br />

4.61<br />

4.65<br />

TMSH D500-150-5<br />

4.92<br />

4.94<br />

4.95<br />

4.96 4.96<br />

4.98<br />

5.00<br />

5.04<br />

5.08<br />

5.10<br />

5.12<br />

5.16<br />

5.20<br />

5.28<br />

5.31<br />

5.35<br />

5.39<br />

TMSH D500-150-6B<br />

4.92<br />

5.35<br />

5.39<br />

5.47<br />

5.51<br />

5.54<br />

5.59<br />

5.63<br />

Coarse Pitch Tooling:<br />

This table is not applicable to the Coarse Pitch system, which can thread mill bores smaller than those<br />

listed above. See the Coarse Pitch section of the various thread standards.<br />

Troubleshooting<br />

Problem Possible Cause Solution<br />

Increased<br />

Cutting speed too high<br />

Reduce cutting speed/use coated insert<br />

TM Technical Data<br />

insert<br />

flank wear<br />

Chipping of<br />

cutting edge<br />

Chip is too thin<br />

Insufficient coolant<br />

Chip is too thick<br />

Vibration<br />

Increase feed rate<br />

Increase coolant flow rate<br />

Reduce feed rate/<br />

Use the tangential arc method/<br />

Increase RPM<br />

Check stability<br />

Material<br />

Build up<br />

on the<br />

Incorrect cutting speed<br />

Unsuitable carbide grade<br />

Change cutting speed<br />

Use a coated carbide grade<br />

Cutting edge<br />

Chatter /<br />

Vibration<br />

Feed rate is too high<br />

Profile is too deep<br />

Reduce the feed<br />

Execute two passes, each with increased cutting depth/<br />

Execute two passes, each cutting only half the thread length<br />

Thread length is too long<br />

Execute two passes, each cutting only half the thread length<br />

GO NOGO Insufficient<br />

thread<br />

accuracy<br />

Tool deflection<br />

Reduce feed rate/<br />

Execute a “zero” cut<br />

260