Arria V Device Handbook - Altera

Arria V Device Handbook - Altera

Arria V Device Handbook - Altera

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Arria</strong> V <strong>Device</strong> <strong>Handbook</strong> Volume 1: <strong>Device</strong> Interfaces and<br />

Integration<br />

101 Innovation Drive<br />

San Jose, CA 95134<br />

www.altera.com<br />

AV-5V2-2.1<br />

<strong>Arria</strong> V <strong>Device</strong> <strong>Handbook</strong><br />

Volume 1: <strong>Device</strong> Interfaces and Integration

© 2012 <strong>Altera</strong> Corporation. All rights reserved. ALTERA, ARRIA, CYCLONE, HARDCOPY, MAX, MEGACORE, NIOS, QUARTUS and STRATIX words and logos<br />

are trademarks of <strong>Altera</strong> Corporation and registered in the U.S. Patent and Trademark Office and in other countries. All other words and logos identified as<br />

trademarks or service marks are the property of their respective holders as described at www.altera.com/common/legal.html. <strong>Altera</strong> warrants performance of its<br />

semiconductor products to current specifications in accordance with <strong>Altera</strong>'s standard warranty, but reserves the right to make changes to any products and<br />

services at any time without notice. <strong>Altera</strong> assumes no responsibility or liability arising out of the application or use of any information, product, or service<br />

described herein except as expressly agreed to in writing by <strong>Altera</strong>. <strong>Altera</strong> customers are advised to obtain the latest version of device specifications before relying<br />

on any published information and before placing orders for products or services.<br />

ISO<br />

9001:2008<br />

Registered<br />

June 2012 <strong>Altera</strong> Corporation <strong>Arria</strong> V <strong>Device</strong> <strong>Handbook</strong><br />

Volume 1: <strong>Device</strong> Interfaces and Integration

Contents<br />

Chapter Revision Dates ...................................................................... xi<br />

Section I. <strong>Device</strong> Core for <strong>Arria</strong> V <strong>Device</strong>s<br />

Revision History ........................................................................ I–1<br />

Chapter 1. Logic Array Blocks and Adaptive Logic Modules in <strong>Arria</strong> V <strong>Device</strong>s<br />

LAB ...................................................................................1–2<br />

MLAB ...............................................................................1–3<br />

Interconnects .........................................................................1–4<br />

LAB Control Signals ...................................................................1–5<br />

ALM Registers ........................................................................1–6<br />

ALM Outputs ........................................................................1–7<br />

ALM Operating Modes ..................................................................1–9<br />

Normal Mode ........................................................................1–9<br />

Extended LUT Mode ..................................................................1–9<br />

Arithmetic Mode .....................................................................1–10<br />

Carry Chain ......................................................................1–11<br />

Shared Arithmetic Mode ..............................................................1–12<br />

Shared Arithmetic Chain ...........................................................1–12<br />

Document Revision History .............................................................1–13<br />

Chapter 2. Memory Blocks in <strong>Arria</strong> V <strong>Device</strong>s<br />

Memory Types ..........................................................................2–1<br />

Memory Features ........................................................................2–2<br />

Memory Modes .........................................................................2–3<br />

Mixed-Width Port Configurations .........................................................2–4<br />

M10K Blocks Mixed-Width Configurations ...............................................2–4<br />

MLABs Mixed-Width Configurations ....................................................2–5<br />

Clocking Modes .........................................................................2–5<br />

Clocking Modes for Each Memory Mode .................................................2–5<br />

Asynchronous Clears ..................................................................2–5<br />

Output Read Data in Simultaneous Read/Write ...........................................2–6<br />

Independent Clock Enables ............................................................2–6<br />

Parity Bit ...............................................................................2–6<br />

Byte Enable .............................................................................2–6<br />

byteena Controls ......................................................................2–7<br />

Data Byte Output .....................................................................2–7<br />

RAM Blocks Operations ...............................................................2–8<br />

Design Considerations ...................................................................2–8<br />

Memory Block Selection ...............................................................2–8<br />

Conflict Resolution ....................................................................2–9<br />

Read-During-Write Behavior ...........................................................2–9<br />

Same-Port Read-During-Write Mode ..................................................2–9<br />

Mixed-Port Read-During-Write Mode ................................................2–10<br />

Power-Up State and Memory Initialization ..............................................2–12<br />

Power Management ..................................................................2–13<br />

Document Revision History .............................................................2–13<br />

June 2012 <strong>Altera</strong> Corporation <strong>Arria</strong> V <strong>Device</strong> <strong>Handbook</strong><br />

Volume 1: <strong>Device</strong> Interfaces and Integration

iv Contents<br />

Chapter 3. Variable-Precision DSP Blocks in <strong>Arria</strong> V <strong>Device</strong>s<br />

Features ................................................................................3–1<br />

Supported Operational Modes ............................................................3–2<br />

Design Considerations ...................................................................3–3<br />

Operational Modes ....................................................................3–3<br />

Pre-Adder ...........................................................................3–3<br />

Internal Coefficient ....................................................................3–3<br />

Accumulator .........................................................................3–3<br />

Chainout Adder ......................................................................3–3<br />

Block Architecture .......................................................................3–4<br />

Input Register Bank ...................................................................3–5<br />

Pre-Adder ...........................................................................3–6<br />

Internal Coefficient ....................................................................3–6<br />

Multipliers ...........................................................................3–7<br />

Adder ...............................................................................3–7<br />

Accumulator and Chainout Adder ......................................................3–7<br />

Systolic Registers .....................................................................3–8<br />

Double Accumulation Register .........................................................3–8<br />

Output Register Bank ..................................................................3–8<br />

Operational Mode Descriptions ...........................................................3–9<br />

Independent Multiplier Mode ..........................................................3–9<br />

Independent Complex Multiplier Mode .................................................3–12<br />

Multiplier Adder Sum Mode ..........................................................3–13<br />

18 x 18 Multiplication Summed with 36-Bit Input Mode ...................................3–14<br />

Systolic FIR Mode ....................................................................3–15<br />

Document Revision History .............................................................3–17<br />

Chapter 4. Clock Networks and PLLs in <strong>Arria</strong> V <strong>Device</strong>s<br />

Clock Networks in <strong>Arria</strong> V <strong>Device</strong>s ........................................................4–1<br />

Global Clock Networks ................................................................4–3<br />

Regional Clock Networks ..............................................................4–4<br />

Periphery Clock Networks .............................................................4–5<br />

Clock Sources Per Quadrant ............................................................4–6<br />

Clock Regions ........................................................................4–7<br />

Entire <strong>Device</strong> Clock Region ..........................................................4–7<br />

Regional Clock Region ..............................................................4–7<br />

Dual-Regional Clock Region .........................................................4–7<br />

Clock Network Sources ................................................................4–8<br />

Dedicated Clock Input Pins ..........................................................4–8<br />

Internal Logic ......................................................................4–8<br />

DPA Outputs ......................................................................4–8<br />

HSSI Outputs ......................................................................4–8<br />

PLL Clock Outputs .................................................................4–8<br />

Clock Input Pin Connections to GCLK and RCLK Networks .............................4–9<br />

Clock Output Connections ............................................................4–12<br />

Clock Control Block ..................................................................4–12<br />

GCLK Control Block ...............................................................4–13<br />

RCLK Control Block ...............................................................4–14<br />

PCLK Control Block ...............................................................4–14<br />

External PLL Clock Output Control Block .............................................4–15<br />

Clock Power Down ...................................................................4–16<br />

Clock Enable Signals .................................................................4–16<br />

<strong>Arria</strong> V PLLs ...........................................................................4–18<br />

<strong>Arria</strong> V <strong>Device</strong> <strong>Handbook</strong> June 2012 <strong>Altera</strong> Corporation<br />

Volume 1: <strong>Device</strong> Interfaces and Integration

Contents v<br />

Fractional PLL Architecture ...........................................................4–23<br />

Fractional PLL Usage ..............................................................4–23<br />

PLL External Clock I/O Pins ..........................................................4–23<br />

PLL Control Signals ..................................................................4–25<br />

pfdena ...........................................................................4–25<br />

areset ............................................................................4–25<br />

locked ............................................................................4–26<br />

Clock Feedback Modes ...............................................................4–26<br />

Source Synchronous Mode ..........................................................4–27<br />

LVDS Compensation Mode .........................................................4–28<br />

Direct Compensation Mode .........................................................4–29<br />

NormalMode .....................................................................4–30<br />

Zero-Delay Buffer Mode ............................................................4–30<br />

External Feedback Mode ...........................................................4–32<br />

Clock Multiplication and Division ......................................................4–33<br />

Programmable Duty Cycle ............................................................4–34<br />

Clock Switchover ....................................................................4–34<br />

Automatic Clock Switchover ........................................................4–35<br />

Manual Clock Switchover ..........................................................4–39<br />

Guidelines ........................................................................4–39<br />

PLL Reconfiguration and Dynamic Phase Shift ...........................................4–40<br />

Document Revision History .............................................................4–41<br />

Section II. I/O Interfaces for <strong>Arria</strong> V <strong>Device</strong>s<br />

Revision History ....................................................................... II–1<br />

Chapter 5. I/O Features in <strong>Arria</strong> V <strong>Device</strong>s<br />

I/O Standards Support ...................................................................5–2<br />

Design Considerations ...................................................................5–4<br />

I/O Bank Restrictions .................................................................5–4<br />

Non-Voltage-Referenced Standards ...................................................5–4<br />

Voltage-Referenced Standards ........................................................5–4<br />

Mixing Voltage-Referenced and Non-Voltage-Referenced Standards ......................5–4<br />

V CCPD Restriction .....................................................................5–5<br />

V CCIO Restriction .....................................................................5–5<br />

V REF Pin Restriction ...................................................................5–5<br />

3.3-V I/O Interface ....................................................................5–5<br />

LVDS Channels .......................................................................5–6<br />

I/O Banks ..............................................................................5–6<br />

Modular I/O Banks ...................................................................5–8<br />

IOE Structure ..........................................................................5–11<br />

Current Strength .....................................................................5–12<br />

MultiVolt I/O Interface ...............................................................5–13<br />

Programmable IOE Features .............................................................5–14<br />

Slew-Rate Control ....................................................................5–14<br />

I/O Delay ...........................................................................5–14<br />

Programmable IOE Delay ...........................................................5–14<br />

Programmable Output Buffer Delay ..................................................5–15<br />

Open-Drain Output ..................................................................5–15<br />

Bus-Hold ...........................................................................5–15<br />

Pull-Up Resistor .....................................................................5–16<br />

Pre-Emphasis ........................................................................5–16<br />

Differential Output Voltage ...........................................................5–16<br />

June 2012 <strong>Altera</strong> Corporation <strong>Arria</strong> V <strong>Device</strong> <strong>Handbook</strong><br />

Volume 1: <strong>Device</strong> Interfaces and Integration

vi Contents<br />

OCT Schemes ..........................................................................5–17<br />

OCT Calibration Block ................................................................5–18<br />

Sharing an OCT Calibration Block on Multiple I/O Banks ...............................5–21<br />

R S OCT with Calibration ..............................................................5–22<br />

R S OCT Without Calibration ...........................................................5–22<br />

R T OCT with Calibration ..............................................................5–23<br />

Dynamic OCT .......................................................................5–24<br />

LVDS Input R D OCT .................................................................5–25<br />

I/O Standards Termination Schemes ......................................................5–26<br />

Single-Ended I/O Standard Termination ................................................5–28<br />

Differential I/O Standard Termination ..................................................5–29<br />

LVDS, RSDS, and Mini-LVDS I/O Standard Termination ...............................5–31<br />

LVPECL I/O Standard Termination ..................................................5–32<br />

Emulated LVDS, RSDS, and Mini-LVDS I/O Standard Termination ......................5–32<br />

Document Revision History .............................................................5–34<br />

Chapter 6. High-Speed Differential I/O Interfaces and DPA in <strong>Arria</strong> V <strong>Device</strong>s<br />

Dedicated High-Speed I/O Circuitries .....................................................6–1<br />

SERDES and DPA Bank Locations .......................................................6–2<br />

LVDS SERDES Circuitry ...............................................................6–3<br />

LVDS Channels .......................................................................6–4<br />

True LVDS Buffers ....................................................................6–4<br />

Differential Transmitter ..................................................................6–6<br />

Transmitter Blocks ....................................................................6–6<br />

Transmitter Clocking ..................................................................6–6<br />

Serializer Bypass for DDR and SDR Operations ...........................................6–7<br />

Programmable V OD .....................................................................................6–8<br />

Programmable Pre-Emphasis ...........................................................6–8<br />

Differential Receiver .....................................................................6–9<br />

Receiver Blocks ......................................................................6–10<br />

DPA Block ........................................................................6–10<br />

Synchronizer ......................................................................6–11<br />

Data Realignment Block (Bit Slip) ....................................................6–12<br />

Deserializer .......................................................................6–13<br />

Receiver Modes ......................................................................6–13<br />

Non-DPAMode ...................................................................6–14<br />

DPAMode .......................................................................6–15<br />

Soft-CDR Mode ...................................................................6–16<br />

Receiver Clocking ....................................................................6–17<br />

Differential I/O Termination ..........................................................6–17<br />

PLLs and Clocking .....................................................................6–18<br />

Source Synchronous Timing Budget ......................................................6–18<br />

Differential Data Orientation ..........................................................6–19<br />

Differential I/O Bit Position ...........................................................6–19<br />

Transmitter Channel-to-Channel Skew ..................................................6–20<br />

Receiver Skew Margin for Non-DPA Mode ..............................................6–21<br />

Design Considerations ..................................................................6–21<br />

Differential Pin Placement .............................................................6–21<br />

DPA-Enabled Channels, DPA-Disabled Channels, and Single-Ended I/Os ................6–22<br />

Guidelines for DPA-Enabled Differential Channels .....................................6–22<br />

Guidelines for DPA-Disabled Differential Channels ....................................6–25<br />

Document Revision History .............................................................6–28<br />

<strong>Arria</strong> V <strong>Device</strong> <strong>Handbook</strong> June 2012 <strong>Altera</strong> Corporation<br />

Volume 1: <strong>Device</strong> Interfaces and Integration

Contents vii<br />

Chapter 7. External Memory Interfaces in <strong>Arria</strong> V <strong>Device</strong>s<br />

Memory Interface Pin Support ............................................................7–2<br />

Design Considerations ...................................................................7–5<br />

Memory Interface .....................................................................7–5<br />

Delay-Locked Loop ...................................................................7–5<br />

DQ/DQS Pins ........................................................................7–6<br />

Using the RZQ Pins in a DQ/DQS Group for Memory Interfaces ............................7–6<br />

PHYCLK Networks ...................................................................7–6<br />

DDR2 SDRAM Interface ...............................................................7–6<br />

DDR3 SDRAM DIMM .................................................................7–7<br />

Hard Memory Controller ..............................................................7–7<br />

Bonding ...........................................................................7–7<br />

External Memory Interface Features .......................................................7–8<br />

DQS Phase-Shift Circuitry ..............................................................7–9<br />

Delay-Locked Loop ................................................................7–11<br />

DLL Phase-Shift ...................................................................7–11<br />

PHY Clock (PHYCLK) Networks .......................................................7–13<br />

DQS Logic Block .....................................................................7–16<br />

Update Enable Circuitry ............................................................7–16<br />

DQS Delay Chain ..................................................................7–17<br />

DQS Postamble Circuitry ...........................................................7–17<br />

HDR Block .......................................................................7–17<br />

Dynamic OCT Control ................................................................7–18<br />

IOE Registers ........................................................................7–19<br />

Input Registers ....................................................................7–19<br />

Output Registers ..................................................................7–19<br />

Delay Chain .........................................................................7–21<br />

Hard Memory Controllers .............................................................7–22<br />

Features of the Hard Memory Controller .............................................7–22<br />

Multiport Logic ...................................................................7–24<br />

Bonding Support ..................................................................7–24<br />

UniPHY IP ............................................................................7–28<br />

Document Revision History .............................................................7–28<br />

Section III. System Integration for <strong>Arria</strong> V <strong>Device</strong>s<br />

Revision History ...................................................................... III–1<br />

Chapter 8. Configuration, Design Security, and Remote System Upgrades in <strong>Arria</strong> V <strong>Device</strong>s<br />

MSEL Pin Settings .......................................................................8–2<br />

Configuration Sequence ..................................................................8–3<br />

PowerUp ............................................................................8–4<br />

V CCPGM Pin........................................................................8–4<br />

V CCPD Pin .........................................................................8–4<br />

Reset ................................................................................8–4<br />

Configuration ........................................................................8–4<br />

Configuration Error Handling ..........................................................8–5<br />

Initialization .........................................................................8–5<br />

User Mode ...........................................................................8–5<br />

<strong>Device</strong> Configuration Pins ................................................................8–6<br />

Configuration Pins Summary ...........................................................8–6<br />

Configuration Pin Options in the Quartus II Software ......................................8–7<br />

Fast Passive Parallel Configuration ........................................................8–7<br />

FPP Single-<strong>Device</strong> Configuration ........................................................8–8<br />

June 2012 <strong>Altera</strong> Corporation <strong>Arria</strong> V <strong>Device</strong> <strong>Handbook</strong><br />

Volume 1: <strong>Device</strong> Interfaces and Integration

viii Contents<br />

FPP Multi-<strong>Device</strong> Configuration ........................................................8–8<br />

Pin Connections and Guidelines ......................................................8–8<br />

Using Multiple Configuration Data ...................................................8–9<br />

Configuring Multiple <strong>Device</strong>s Using One Configuration Data ...........................8–10<br />

Active Serial Configuration ..............................................................8–11<br />

DATA Clock (DCLK) .................................................................8–11<br />

AS Single-<strong>Device</strong> Configuration .......................................................8–12<br />

AS Multi-<strong>Device</strong> Configuration ........................................................8–13<br />

Pin Connections and Guidelines .....................................................8–13<br />

Using Multiple Configuration Data ..................................................8–14<br />

Configuring Multiple <strong>Device</strong>s Using One Configuration Data ...........................8–15<br />

Estimating the AS Configuration Time ..................................................8–15<br />

Using EPCS and EPCQ <strong>Device</strong>s ........................................................8–16<br />

Controlling EPCS and EPCQ <strong>Device</strong>s .................................................8–16<br />

Trace Length and Loading ..........................................................8–16<br />

Programming EPCS and EPCQ <strong>Device</strong>s ..............................................8–17<br />

Passive Serial Configuration .............................................................8–21<br />

PS Single-<strong>Device</strong> Configuration ........................................................8–21<br />

PS Multi-<strong>Device</strong> Configuration ........................................................8–23<br />

Pin Connections and Guidelines .....................................................8–23<br />

Using Multiple Configuration Data ..................................................8–23<br />

Configuring Multiple <strong>Device</strong>s Using One Configuration Data ...........................8–24<br />

Using PC Host and Download Cable .................................................8–25<br />

JTAG Configuration ....................................................................8–26<br />

JTAG Single-<strong>Device</strong> Configuration .....................................................8–26<br />

JTAG Multi-<strong>Device</strong> Configuration ......................................................8–29<br />

CONFIG_IO JTAG Instruction .........................................................8–30<br />

Configuration Data Compression .........................................................8–30<br />

Enabling Compression Before Design Compilation .......................................8–30<br />

Enabling Compression After Design Compilation ........................................8–31<br />

Using Compression in Multi-<strong>Device</strong> Configuration .......................................8–31<br />

Remote System Upgrades ...............................................................8–32<br />

Configuration Images ................................................................8–32<br />

Configuration Sequence ..............................................................8–33<br />

Remote System Upgrade Circuitry .....................................................8–34<br />

Enabling Remote System Upgrade Circuitry .............................................8–35<br />

Remote System Upgrade Registers .....................................................8–35<br />

Control Register ...................................................................8–36<br />

Status Register ....................................................................8–36<br />

Remote System Upgrade State Machine .................................................8–36<br />

User Watchdog Timer ................................................................8–37<br />

Design Security ........................................................................8–37<br />

JTAG Secure Mode ...................................................................8–38<br />

Security Key Types ...................................................................8–39<br />

Security Modes ......................................................................8–39<br />

Design Security Implementation Steps ..................................................8–40<br />

Document Revision History .............................................................8–41<br />

Chapter 9. SEU Mitigation in <strong>Arria</strong> V <strong>Device</strong>s<br />

Basic Description ........................................................................9–1<br />

Error Detection Features .................................................................9–1<br />

Types of Error Detection .................................................................9–2<br />

Configuration Error Detection ..........................................................9–2<br />

User Mode Error Detection .............................................................9–2<br />

<strong>Arria</strong> V <strong>Device</strong> <strong>Handbook</strong> June 2012 <strong>Altera</strong> Corporation<br />

Volume 1: <strong>Device</strong> Interfaces and Integration

Contents ix<br />

Error Detection Components ..............................................................9–3<br />

Error Detection Pin ....................................................................9–3<br />

Error Detection Registers ...............................................................9–3<br />

Error Message Register ................................................................9–5<br />

Storage Size for Error Detection .........................................................9–5<br />

Error Detection Timing ...................................................................9–6<br />

Minimum EMR Update Interval ........................................................9–6<br />

Error Detection Frequency .............................................................9–6<br />

CRC Calculation Time .................................................................9–7<br />

Using the Error Detection Feature .........................................................9–8<br />

Enabling the User Mode Error Detection .................................................9–8<br />

Error Detection Process ................................................................9–8<br />

Reading the Error Location Bit Through JTAG ............................................9–9<br />

Recovering From CRC Errors ...........................................................9–9<br />

Testing the Error Detection Block ..........................................................9–9<br />

Error Detection Instruction .............................................................9–9<br />

JTAG Fault Injection Register ..........................................................9–10<br />

Automating the Testing Process ........................................................9–10<br />

Document Revision History .............................................................9–10<br />

Chapter 10. JTAG Boundary-Scan Testing in <strong>Arria</strong> V <strong>Device</strong>s<br />

BST Operation Control ..................................................................10–1<br />

IDCODE ............................................................................10–1<br />

Supported JTAG Instruction ...........................................................10–2<br />

JTAG Secure Mode ................................................................10–4<br />

JTAG Private Instruction ..............................................................10–4<br />

I/O Voltage for JTAG Operation .........................................................10–4<br />

Enabling and Disabling IEEE Std. 1149.1 BST Circuitry ......................................10–5<br />

Performing BST ........................................................................10–5<br />

Guidelines for IEEE Std. 1149.1 Boundary-Scan Testing ......................................10–6<br />

IEEE Std. 1149.1 BST Architecture ........................................................10–7<br />

IEEE Std. 1149.1 BST Functionality .....................................................10–7<br />

IEEE Std. 1149.1 BST Circuitry Registers ................................................10–7<br />

IEEE Std. 1149.1 BST Pin Function ......................................................10–8<br />

IEEE Std. 1149.1 Boundary-Scan Register ................................................10–9<br />

Boundary-Scan Cells of a <strong>Arria</strong> V <strong>Device</strong> I/O Pin ......................................10–9<br />

IEEE Std. 1149.1 TAP Controller ......................................................10–11<br />

IEEE Std. 1149.1 JTAG Mandatory Instruction .............................................10–14<br />

SAMPLE/PRELOAD Instruction Mode ................................................10–14<br />

EXTEST Instruction Mode ............................................................10–16<br />

BYPASS Instruction Mode ............................................................10–18<br />

Document Revision History ............................................................10–19<br />

Chapter 11. Power Management in <strong>Arria</strong> V <strong>Device</strong>s<br />

Power Consumption ....................................................................11–2<br />

Internal Temperature Sensing Diode ......................................................11–2<br />

Hot-Socketing Feature ..................................................................11–3<br />

Hot-Socketing Implementation ...........................................................11–4<br />

Power-Up Sequencing ..................................................................11–5<br />

Power-On Reset Circuitry ...............................................................11–6<br />

Document Revision History .............................................................11–8<br />

June 2012 <strong>Altera</strong> Corporation <strong>Arria</strong> V <strong>Device</strong> <strong>Handbook</strong><br />

Volume 1: <strong>Device</strong> Interfaces and Integration

x Contents<br />

Additional Information<br />

How to Contact <strong>Altera</strong> ................................................................ Info–1<br />

Typographic Conventions ............................................................. Info–1<br />

<strong>Arria</strong> V <strong>Device</strong> <strong>Handbook</strong> June 2012 <strong>Altera</strong> Corporation<br />

Volume 1: <strong>Device</strong> Interfaces and Integration

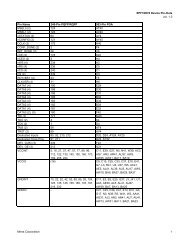

Chapter Revision Dates<br />

The chapters in this document, Volume 1: <strong>Device</strong> Interfaces and Integration, were<br />

revised on the following dates. Where chapters or groups of chapters are available<br />

separately, part numbers are listed.<br />

Part Number:<br />

Chapter 1. Logic Array Blocks and Adaptive Logic Modules in <strong>Arria</strong> V <strong>Device</strong>s<br />

Revised: June 2012<br />

Part Number: AV-52001-2.0<br />

Chapter 2. Memory Blocks in <strong>Arria</strong> V <strong>Device</strong>s<br />

Revised: June 2012<br />

Part Number: AV-52002-2.0<br />

Chapter 3. Variable-Precision DSP Blocks in <strong>Arria</strong> V <strong>Device</strong>s<br />

Revised: June 2012<br />

Part Number: AV-52003-2.0<br />

Chapter 4. Clock Networks and PLLs in <strong>Arria</strong> V <strong>Device</strong>s<br />

Revised: June 2012<br />

Part Number: AV-52004-2.0<br />

Chapter 5. I/O Features in <strong>Arria</strong> V <strong>Device</strong>s<br />

Revised: June 2012<br />

Part Number: AV52005-2.0<br />

Chapter 6. High-Speed Differential I/O Interfaces and DPA in <strong>Arria</strong> V <strong>Device</strong>s<br />

Revised: June 2012<br />

Part Number: AV52006-2.0<br />

Chapter 7. External Memory Interfaces in <strong>Arria</strong> V <strong>Device</strong>s<br />

Revised: June 2012<br />

Part Number: AV52007-2.0<br />

Chapter 8. Configuration, Design Security, and Remote System Upgrades in <strong>Arria</strong> V <strong>Device</strong>s<br />

Revised: June 2012<br />

Part Number: AV-52008-2.0<br />

Chapter 9. SEU Mitigation in <strong>Arria</strong> V <strong>Device</strong>s<br />

Revised: June 2012<br />

Part Number: AV-52009-2.0<br />

Chapter 10. JTAG Boundary-Scan Testing in <strong>Arria</strong> V <strong>Device</strong>s<br />

Revised: June 2012<br />

Part Number: AV-52010-2.0<br />

Chapter 11. Power Management in <strong>Arria</strong> V <strong>Device</strong>s<br />

Revised: June 2012<br />

Part Number: AV-52011-2.0<br />

June 2012 <strong>Altera</strong> Corporation <strong>Arria</strong> V <strong>Device</strong> <strong>Handbook</strong><br />

Volume 1: <strong>Device</strong> Interfaces and Integration

xii<br />

<strong>Arria</strong> V <strong>Device</strong> <strong>Handbook</strong> June 2012 <strong>Altera</strong> Corporation<br />

Volume 1: <strong>Device</strong> Interfaces and Integration

Revision History<br />

© 2012 <strong>Altera</strong> Corporation. All rights reserved. ALTERA, ARRIA, CYCLONE, HARDCOPY, MAX, MEGACORE, NIOS, QUARTUS and STRATIX words and logos<br />

are trademarks of <strong>Altera</strong> Corporation and registered in the U.S. Patent and Trademark Office and in other countries. All other words and logos identified as<br />

trademarks or service marks are the property of their respective holders as described at www.altera.com/common/legal.html. <strong>Altera</strong> warrants performance of its<br />

semiconductor products to current specifications in accordance with <strong>Altera</strong>'s standard warranty, but reserves the right to make changes to any products and<br />

services at any time without notice. <strong>Altera</strong> assumes no responsibility or liability arising out of the application or use of any information, product, or service<br />

described herein except as expressly agreed to in writing by <strong>Altera</strong>. <strong>Altera</strong> customers are advised to obtain the latest version of device specifications before relying<br />

on any published information and before placing orders for products or services.<br />

<strong>Arria</strong> V <strong>Device</strong> <strong>Handbook</strong><br />

Volume 1: <strong>Device</strong> Interfaces and Integration<br />

June 2012<br />

Section I. <strong>Device</strong> Core for <strong>Arria</strong> V <strong>Device</strong>s<br />

This section provides a complete overview of all features relating to the <strong>Arria</strong> ® V<br />

device family. This section includes the following chapters:<br />

■ Chapter 1, Logic Array Blocks and Adaptive Logic Modules in <strong>Arria</strong> V <strong>Device</strong>s<br />

■ Chapter 2, Memory Blocks in <strong>Arria</strong> V <strong>Device</strong>s<br />

■ Chapter 3, Variable-Precision DSP Blocks in <strong>Arria</strong> V <strong>Device</strong>s<br />

■ Chapter 4, Clock Networks and PLLs in <strong>Arria</strong> V <strong>Device</strong>s<br />

Refer to each chapter for its own specific revision history. For information about when<br />

each chapter was updated, refer to the Chapter Revision Dates section, which appears<br />

in this volume.<br />

ISO<br />

9001:2008<br />

Registered

I–2<br />

Revision History<br />

<strong>Arria</strong> V <strong>Device</strong> <strong>Handbook</strong> June 2012 <strong>Altera</strong> Corporation<br />

Volume 1: <strong>Device</strong> Interfaces and Integration

June 2012<br />

AV-52001-2.0<br />

AV-52001-2.0<br />

© 2012 <strong>Altera</strong> Corporation. All rights reserved. ALTERA, ARRIA, CYCLONE, HARDCOPY, MAX, MEGACORE, NIOS, QUARTUS and STRATIX words and logos<br />

are trademarks of <strong>Altera</strong> Corporation and registered in the U.S. Patent and Trademark Office and in other countries. All other words and logos identified as<br />

trademarks or service marks are the property of their respective holders as described at www.altera.com/common/legal.html. <strong>Altera</strong> warrants performance of its<br />

semiconductor products to current specifications in accordance with <strong>Altera</strong>'s standard warranty, but reserves the right to make changes to any products and<br />

services at any time without notice. <strong>Altera</strong> assumes no responsibility or liability arising out of the application or use of any information, product, or service<br />

described herein except as expressly agreed to in writing by <strong>Altera</strong>. <strong>Altera</strong> customers are advised to obtain the latest version of device specifications before relying<br />

on any published information and before placing orders for products or services.<br />

<strong>Arria</strong> V <strong>Device</strong> <strong>Handbook</strong><br />

Volume 1: <strong>Device</strong> Interfaces and Integration<br />

June 2012<br />

1. Logic Array Blocks and Adaptive Logic<br />

Modules in <strong>Arria</strong> V <strong>Device</strong>s<br />

This chapter describes the features of the logic array block (LAB) in the <strong>Arria</strong> ® V core<br />

fabric.<br />

The LAB is composed of basic building blocks known as adaptive logic modules<br />

(ALMs) that you can configure to implement logic functions, arithmetic functions,<br />

and register functions.<br />

You can use a quarter of the available LABs in <strong>Arria</strong> V devices as a memory LAB<br />

(MLAB).<br />

The Quartus ® II software and other supported third-party synthesis tools, in<br />

conjunction with parameterized functions such as the library of parameterized<br />

modules (LPM), automatically choose the appropriate mode for common functions<br />

such as counters, adders, subtractors, and arithmetic functions.<br />

This chapter contains the following sections:<br />

■ “LAB”<br />

■ “ALM Operating Modes” on page 1–9<br />

ISO<br />

9001:2008<br />

Registered<br />

Feedback Subscribe

1–2 Chapter 1: Logic Array Blocks and Adaptive Logic Modules in <strong>Arria</strong> V <strong>Device</strong>s<br />

LAB<br />

LAB<br />

The LABs are configurable logic blocks that consist of a group of logic resources. Each<br />

LAB contains dedicated logic for driving control signals to its ALMs.<br />

MLAB is a superset of the LAB and includes all the LAB features.<br />

Figure 1–1 shows an overview of the <strong>Arria</strong> V LAB and MLAB structure with the LAB<br />

interconnects.<br />

Figure 1–1. LAB Structure and Interconnects Overview in <strong>Arria</strong> V <strong>Device</strong>s<br />

R14<br />

R3/R6<br />

Direct link<br />

interconnect from<br />

adjacent block (1)<br />

Direct link<br />

interconnect to<br />

adjacent block<br />

Local interconnect<br />

LAB<br />

C2/C4 C12<br />

Row interconnects of<br />

variable speed and length<br />

MLAB<br />

Fast local interconnect is driven<br />

from either sides by column interconnect<br />

and LABs, and from above by row interconnect<br />

Note to Figure 1–1:<br />

(1) Connects to adjacent LABs, memory blocks, digital signal processing (DSP) blocks, or I/O element (IOE) outputs.<br />

Column interconnects of<br />

variable speed and length<br />

<strong>Arria</strong> V <strong>Device</strong> <strong>Handbook</strong> June 2012 <strong>Altera</strong> Corporation<br />

Volume 1: <strong>Device</strong> Interfaces and Integration<br />

ALMs<br />

Direct link<br />

interconnect from<br />

adjacent block<br />

Direct link<br />

interconnect to<br />

adjacent block

Chapter 1: Logic Array Blocks and Adaptive Logic Modules in <strong>Arria</strong> V <strong>Device</strong>s 1–3<br />

LAB<br />

MLAB<br />

Each MLAB supports a maximum of 640 bits of simple dual-port SRAM.<br />

You can configure each ALM in an MLAB as a 32 x 2 memory block, resulting in a<br />

configuration of 32 x 20 simple dual-port SRAM blocks.<br />

Figure 1–2 shows the LAB and MLAB topology.<br />

Figure 1–2. LAB and MLAB Structure for <strong>Arria</strong> V <strong>Device</strong>s<br />

(1)<br />

LUT-based-32 x 2<br />

Simple dual port SRAM<br />

(1)<br />

LUT-based-32 x 2<br />

Simple dual port SRAM<br />

LUT-based-32 x 2 (1)<br />

Simple dual port SRAM<br />

LUT-based-32 x 2 (1)<br />

Simple dual port SRAM<br />

LUT-based-32 x 2 (1)<br />

Simple dual port SRAM<br />

LUT-based-32 x 2<br />

(1)<br />

Simple dual port SRAM<br />

LUT-based-32 x 2 (1)<br />

Simple dual port SRAM<br />

LUT-based-32 x 2<br />

(1)<br />

Simple dual port SRAM<br />

LUT-based-32 x 2 (1)<br />

Simple dual port SRAM<br />

LUT-based-32 x 2 (1)<br />

Simple dual port SRAM<br />

MLAB LAB<br />

Note to Figure 1–2:<br />

(1) You can use an MLAB ALM as a regular LAB ALM or configure it as a dual-port SRAM.<br />

June 2012 <strong>Altera</strong> Corporation <strong>Arria</strong> V <strong>Device</strong> <strong>Handbook</strong><br />

Volume 1: <strong>Device</strong> Interfaces and Integration<br />

ALM<br />

ALM<br />

ALM<br />

ALM<br />

ALM<br />

LAB Control Block LAB Control Block<br />

ALM<br />

ALM<br />

ALM<br />

ALM<br />

ALM

1–4 Chapter 1: Logic Array Blocks and Adaptive Logic Modules in <strong>Arria</strong> V <strong>Device</strong>s<br />

LAB<br />

Interconnects<br />

Each LAB can drive 30 ALMs through fast-local and direct-link interconnects. Ten<br />

ALMs are in any given LAB and ten ALMs are in each of the adjacent LABs.<br />

The local interconnect can drive ALMs in the same LAB using column and row<br />

interconnects and ALM outputs in the same LAB.<br />

Neighboring LABs, MLABs, M10K blocks, or digital signal processing (DSP) blocks<br />

from the left or right can also drive the LAB’s local interconnect using the direct link<br />

connection.<br />

The direct link connection feature minimizes the use of row and column<br />

interconnects, providing higher performance and flexibility.<br />

Figure 1–3 shows the LAB fast-local and direct-link interconnects.<br />

Figure 1–3. Direct Link and Fast Local Interconnects for <strong>Arria</strong> V <strong>Device</strong>s<br />

Direct link<br />

interconnect<br />

to left<br />

Direct link interconnect from<br />

left LAB, memory block,<br />

DSP block, or IOE output<br />

ALMs ALMs<br />

MLAB<br />

Fast local<br />

interconnect<br />

<strong>Arria</strong> V <strong>Device</strong> <strong>Handbook</strong> June 2012 <strong>Altera</strong> Corporation<br />

Volume 1: <strong>Device</strong> Interfaces and Integration<br />

LAB<br />

Direct link interconnect from<br />

right LAB, memory block,<br />

DSP block, or IOE output<br />

Direct link<br />

interconnect<br />

to right

Chapter 1: Logic Array Blocks and Adaptive Logic Modules in <strong>Arria</strong> V <strong>Device</strong>s 1–5<br />

LAB<br />

LAB Control Signals<br />

Each LAB contains dedicated logic for driving the control signals to its ALMs, and has<br />

two unique clock sources and three clock enable signals.<br />

The LAB control block generates up to three clocks using the two clock sources and<br />

three clock enable signals. Each clock and the clock enable signals are linked.<br />

De-asserting the clock enable signal turns off the corresponding LAB-wide clock.<br />

Figure 1–4 shows the clock sources and clock enable signals in an LAB.<br />

Figure 1–4. LAB-Wide Control Signals for <strong>Arria</strong> V <strong>Device</strong>s (1)<br />

Dedicated Row LAB Clocks<br />

Local Interconnect<br />

Local Interconnect<br />

Local Interconnect<br />

Local Interconnect<br />

Note to Figure 1–4:<br />

(1) For more information, refer to Figure 1–6 on page 1–8.<br />

6<br />

6<br />

6<br />

There are two unique<br />

clock signals per LAB.<br />

labclk0 labclk1 labclk2 syncload<br />

labclr1<br />

labclkena0<br />

or asyncload<br />

or labpreset<br />

labclkena1 labclkena2 labclr0 synclr<br />

June 2012 <strong>Altera</strong> Corporation <strong>Arria</strong> V <strong>Device</strong> <strong>Handbook</strong><br />

Volume 1: <strong>Device</strong> Interfaces and Integration

1–6 Chapter 1: Logic Array Blocks and Adaptive Logic Modules in <strong>Arria</strong> V <strong>Device</strong>s<br />

LAB<br />

ALM Registers<br />

One ALM contains four programmable registers. Each register has data, clock,<br />

synchronous and asynchronous clear, and synchronous load functions.<br />

Global signals, general-purpose I/O (GPIO) pins, or any internal logic can drive the<br />

clock and clear control signals of an ALM register.<br />

GPIO pins or internal logic drives the clock enable signal.<br />

For combinational functions, the registers are bypassed and the output of the look-up<br />

table (LUT) drives directly to the outputs of an ALM.<br />

Figure 1–5 shows a high-level block diagram of the <strong>Arria</strong> V ALM.<br />

Figure 1–5. High-Level Block Diagram of the <strong>Arria</strong> V ALM<br />

dataf0<br />

datae0<br />

dataa<br />

datab<br />

datac<br />

datad<br />

datae1<br />

dataf1<br />

shared_arith_in<br />

6-Input LUT<br />

6-Input LUT<br />

shared_arith_out<br />

carry_in<br />

adder0<br />

adder1<br />

carry_out<br />

Combinational/<br />

Memory ALUT0<br />

Combinational/<br />

Memory ALUT1<br />

reg_chain_in<br />

1 The Quartus II software automatically configures the ALMs for optimized<br />

performance.<br />

<strong>Arria</strong> V <strong>Device</strong> <strong>Handbook</strong> June 2012 <strong>Altera</strong> Corporation<br />

Volume 1: <strong>Device</strong> Interfaces and Integration<br />

labclk<br />

reg_chain_out<br />

D Q<br />

reg0<br />

D Q<br />

reg1<br />

D Q<br />

reg2<br />

D Q<br />

reg3<br />

To general or<br />

local routing<br />

To general or<br />

local routing<br />

To general or<br />

local routing<br />

To general or<br />

local routing<br />

To general or<br />

local routing<br />

To general or<br />

local routing<br />

To general or<br />

local routing<br />

To general or<br />

local routing

Chapter 1: Logic Array Blocks and Adaptive Logic Modules in <strong>Arria</strong> V <strong>Device</strong>s 1–7<br />

LAB<br />

ALM Outputs<br />

The LUT, adder, or register output can drive the ALM outputs. There are two sets of<br />

outputs—general routing outputs and register chain outputs.<br />

For each set of output drivers, two ALM outputs can drive column, row, or direct link<br />

routing connections, and one of these ALM outputs can also drive local interconnect<br />

resources. The LUT or adder can drive one output while the register drives another<br />

output.<br />

Register packing improves device utilization by allowing unrelated register and<br />

combinational logic to be packed into a single ALM. Another mechanism to improve<br />

fitting is to allow the register output to feed back into the look-up table (LUT) of the<br />

same ALM so that the register is packed with its own fan-out LUT. The ALM can also<br />

drive out registered and unregistered versions of the LUT or adder output.<br />

June 2012 <strong>Altera</strong> Corporation <strong>Arria</strong> V <strong>Device</strong> <strong>Handbook</strong><br />

Volume 1: <strong>Device</strong> Interfaces and Integration

1–8 Chapter 1: Logic Array Blocks and Adaptive Logic Modules in <strong>Arria</strong> V <strong>Device</strong>s<br />

LAB<br />

Figure 1–6 shows a detailed view of all the connections in an ALM.<br />

Figure 1–6. ALM Connection Details for <strong>Arria</strong> V <strong>Device</strong>s<br />

dataf0<br />

datae0<br />

dataa<br />

datab<br />

datac0<br />

datac1<br />

datae1<br />

dataf1<br />

shared_arith_in<br />

4-Input<br />

LUT<br />

3-Input<br />

LUT<br />

3-Input<br />

LUT<br />

4-Input<br />

LUT<br />

3-Input<br />

LUT<br />

3-Input<br />

LUT<br />

shared_arith_out<br />

carry_in<br />

+<br />

+<br />

carry_out<br />

GND<br />

VCC<br />

syncload<br />

aclr[1:0]<br />

clk[2:0] sclr reg_chain_in<br />

D Q<br />

D Q<br />

<strong>Arria</strong> V <strong>Device</strong> <strong>Handbook</strong> June 2012 <strong>Altera</strong> Corporation<br />

Volume 1: <strong>Device</strong> Interfaces and Integration<br />

CLR<br />

CLR<br />

D Q<br />

CLR<br />

CLR<br />

D Q<br />

row, column<br />

direct link routing<br />

row, column<br />

direct link routing<br />

local<br />

interconnect<br />

row, column<br />

direct link routing<br />

row, column<br />

direct link routing<br />

local<br />

interconnect<br />

reg_chain_out

Chapter 1: Logic Array Blocks and Adaptive Logic Modules in <strong>Arria</strong> V <strong>Device</strong>s 1–9<br />

ALM Operating Modes<br />

ALM Operating Modes<br />

Normal Mode<br />

The <strong>Arria</strong> V ALM operates in any of the following modes:<br />

■ Normal Mode<br />

■ Extended LUT Mode<br />

■ Arithmetic Mode<br />

■ Shared Arithmetic Mode<br />

Up to eight data inputs from the LAB local interconnect are inputs to the<br />

combinational logic. Normal mode allows two functions to be implemented in one<br />

<strong>Arria</strong> V ALM, or a single function of up to six inputs.<br />

The ALM can support certain combinations of completely independent functions and<br />

various combinations of functions that have common inputs.<br />

Extended LUT Mode<br />

In this mode, if the 7-input function is unregistered, the unused eighth input is<br />

available for register packing.<br />

1 Functions that fit into the template, as shown in Figure 1–7, often appear in designs as<br />

“if-else” statements in Verilog HDL or VHDL code.<br />

Figure 1–7 shows the template of supported 7-input functions using extended LUT<br />

mode.<br />

Figure 1–7. Template for Supported 7-Input Functions in Extended LUT Mode in <strong>Arria</strong> V <strong>Device</strong>s<br />

datae0<br />

datac<br />

dataa<br />

datab<br />

datad<br />

dataf0<br />

datae1<br />

dataf1<br />

5-Input<br />

LUT<br />

5-Input<br />

LUT<br />

This input is available<br />

for register packing.<br />

combout0<br />

June 2012 <strong>Altera</strong> Corporation <strong>Arria</strong> V <strong>Device</strong> <strong>Handbook</strong><br />

Volume 1: <strong>Device</strong> Interfaces and Integration<br />

D Q<br />

reg0<br />

To gener al or<br />

local routing<br />

To gener al or<br />

local routing

1–10 Chapter 1: Logic Array Blocks and Adaptive Logic Modules in <strong>Arria</strong> V <strong>Device</strong>s<br />

ALM Operating Modes<br />

Arithmetic Mode<br />

The ALM in arithmetic mode uses two sets of two 4-input LUTs along with two<br />

dedicated full adders.<br />

The dedicated adders allow the LUTs to perform pre-adder logic; therefore, each<br />

adder can add the output of two 4-input functions.<br />

The ALM supports simultaneous use of the adder’s carry output along with<br />

combinational logic outputs. The adder output is ignored in this operation.<br />

Using the adder with the combinational logic output provides resource savings of up<br />

to 50% for functions that can use this mode.<br />

Figure 1–8 shows an ALM in arithmetic mode.<br />

Figure 1–8. ALM in Arithmetic Mode for <strong>Arria</strong> V <strong>Device</strong>s<br />

datae0<br />

dataf0<br />

datac<br />

datab<br />

dataa<br />

datad<br />

datae1<br />

dataf1<br />

<strong>Arria</strong> V <strong>Device</strong> <strong>Handbook</strong> June 2012 <strong>Altera</strong> Corporation<br />

Volume 1: <strong>Device</strong> Interfaces and Integration<br />

4-Input<br />

LUT<br />

4-Input<br />

LUT<br />

4-Input<br />

LUT<br />

4-Input<br />

LUT<br />

carry_in<br />

carry_out<br />

adder0<br />

adder1<br />

D Q<br />

reg0<br />

D Q<br />

reg1<br />

D Q<br />

reg2<br />

D Q<br />

reg3<br />

To general or<br />

local routing<br />

To general or<br />

local routing<br />

To general or<br />

local routing<br />

To general or<br />

local routing<br />

To general or<br />

local routing<br />

To general or<br />

local routing<br />

To general or<br />

local routing<br />

To general or<br />

local routing

Chapter 1: Logic Array Blocks and Adaptive Logic Modules in <strong>Arria</strong> V <strong>Device</strong>s 1–11<br />

ALM Operating Modes<br />

Carry Chain<br />

The carry chain provides a fast carry function between the dedicated adders in<br />

arithmetic or shared arithmetic mode.<br />

The two-bit carry select feature in <strong>Arria</strong> V devices halves the propagation delay of<br />

carry chains within the ALM. Carry chains can begin in either the first ALM or the<br />

fifth ALM in a LAB. The final carry-out signal is routed to an ALM, where it is fed to<br />

local, row, or column interconnects.<br />

To avoid routing congestion in one small area of the device when a high fan-in<br />

arithmetic function is implemented, the LAB can support carry chains that only use<br />

either the top half or bottom half of the LAB before connecting to the next LAB. This<br />

leaves the other half of the ALMs in the LAB available for implementing narrower<br />

fan-in functions in normal mode. Carry chains that use the top five ALMs in the first<br />

LAB carry into the top half of the ALMs in the next LAB in the column. Carry chains<br />

that use the bottom five ALMs in the first LAB carry into the bottom half of the ALMs<br />

in the next LAB within the column. You can bypass the top-half of the LAB columns<br />

and bottom-half of the MLAB columns.<br />

The Quartus II Compiler creates carry chains longer than 20 ALMs (10 ALMs in<br />

arithmetic or shared arithmetic mode) by linking LABs together automatically. For<br />

enhanced fitting, a long carry chain runs vertically, allowing fast horizontal<br />

connections to the TriMatrix memory and DSP blocks. A carry chain can continue as<br />

far as a full column.<br />

June 2012 <strong>Altera</strong> Corporation <strong>Arria</strong> V <strong>Device</strong> <strong>Handbook</strong><br />

Volume 1: <strong>Device</strong> Interfaces and Integration

1–12 Chapter 1: Logic Array Blocks and Adaptive Logic Modules in <strong>Arria</strong> V <strong>Device</strong>s<br />

ALM Operating Modes<br />

Shared Arithmetic Mode<br />

The ALM in shared arithmetic mode can implement a 3-input add in the ALM.<br />

This mode configures the ALM with four 4-input LUTs. Each LUT either computes<br />

the sum of three inputs or the carry of three inputs. The output of the carry<br />

computation is fed to the next adder using a dedicated connection called the shared<br />

arithmetic chain.<br />

Figure 1–9 shows the ALM using this feature.<br />

Figure 1–9. ALM in Shared Arithmetic Mode for <strong>Arria</strong> V <strong>Device</strong>s<br />

datae0<br />

datac<br />

datab<br />

dataa<br />

datad<br />

datae1<br />

shared_arith_in<br />

shared_arith_out<br />

Shared Arithmetic Chain<br />

The shared arithmetic chain available in enhanced arithmetic mode allows the ALM<br />

to implement a 3-input adder. This significantly reduces the resources necessary to<br />

implement large adder trees or correlator functions.<br />

Similar to carry chains, the top and bottom half of the shared arithmetic chains in<br />

alternate LAB columns can be bypassed. This capability allows the shared arithmetic<br />

chain to cascade through half of the ALMs in an LAB while leaving the other half<br />

available for narrower fan-in functionality. In every LAB column is top-half<br />

bypassable; while in MLAB columns are bottom-half bypassable.<br />

The shared arithmetic chain can begin in either the first or sixth ALM in an LAB. The<br />

Quartus II Compiler creates shared arithmetic chains longer than 20 ALMs (10 ALMs<br />

in arithmetic or shared arithmetic mode) by linking LABs together automatically. To<br />

enhanced fitting, a long shared arithmetic chain runs vertically, allowing fast<br />

horizontal connections to the TriMatrix memory and DSP blocks. A shared arithmetic<br />

chain can continue as far as a full column.<br />

<strong>Arria</strong> V <strong>Device</strong> <strong>Handbook</strong> June 2012 <strong>Altera</strong> Corporation<br />

Volume 1: <strong>Device</strong> Interfaces and Integration<br />

4-Input<br />

LUT<br />

4-Input<br />

LUT<br />

4-Input<br />

LUT<br />

4-Input<br />

LUT<br />

carry_in<br />

carry_out<br />

labclk<br />

D Q<br />

reg0<br />

D Q<br />

reg1<br />

D Q<br />

reg2<br />

D Q<br />

reg3<br />

To general or<br />

local routing<br />

To general or<br />

local routing<br />

To general or<br />

local routing<br />

To general or<br />

local routing<br />

To general or<br />

local routing<br />

To general or<br />

local routing<br />

To general or<br />

local routing<br />

To general or<br />

local routing

Chapter 1: Logic Array Blocks and Adaptive Logic Modules in <strong>Arria</strong> V <strong>Device</strong>s 1–13<br />

Document Revision History<br />

Document Revision History<br />

Table 1–1. Document Revision History<br />

Table 1–1 lists the revision history for this chapter.<br />

Date Version Changes<br />

June 2012 2.0<br />

Updated for the Quartus II software v12.0 release:<br />

■ Restructured chapter.<br />

■ Updated Figure 1–6.<br />

November 2011 1.1 Restructured chapter.<br />

May 2011 1.0 Initial release.<br />

June 2012 <strong>Altera</strong> Corporation <strong>Arria</strong> V <strong>Device</strong> <strong>Handbook</strong><br />

Volume 1: <strong>Device</strong> Interfaces and Integration

1–14 Chapter 1: Logic Array Blocks and Adaptive Logic Modules in <strong>Arria</strong> V <strong>Device</strong>s<br />

Document Revision History<br />

<strong>Arria</strong> V <strong>Device</strong> <strong>Handbook</strong> June 2012 <strong>Altera</strong> Corporation<br />

Volume 1: <strong>Device</strong> Interfaces and Integration

June 2012<br />

AV-52002-2.0<br />

AV-52002-2.0<br />

Memory Types<br />

© 2012 <strong>Altera</strong> Corporation. All rights reserved. ALTERA, ARRIA, CYCLONE, HARDCOPY, MAX, MEGACORE, NIOS, QUARTUS and STRATIX words and logos<br />

are trademarks of <strong>Altera</strong> Corporation and registered in the U.S. Patent and Trademark Office and in other countries. All other words and logos identified as<br />

trademarks or service marks are the property of their respective holders as described at www.altera.com/common/legal.html. <strong>Altera</strong> warrants performance of its<br />

semiconductor products to current specifications in accordance with <strong>Altera</strong>'s standard warranty, but reserves the right to make changes to any products and<br />

services at any time without notice. <strong>Altera</strong> assumes no responsibility or liability arising out of the application or use of any information, product, or service<br />

described herein except as expressly agreed to in writing by <strong>Altera</strong>. <strong>Altera</strong> customers are advised to obtain the latest version of device specifications before relying<br />

on any published information and before placing orders for products or services.<br />

<strong>Arria</strong> V <strong>Device</strong> <strong>Handbook</strong><br />

Volume 1: <strong>Device</strong> Interfaces and Integration<br />

June 2012<br />

2. Memory Blocks in <strong>Arria</strong> V <strong>Device</strong>s<br />

This chapter describes the embedded memory blocks in <strong>Arria</strong> ® V devices.<br />

The memory blocks in <strong>Arria</strong> V devices provide different sizes of embedded SRAM to<br />

fit your design requirements.<br />

This chapter contains the following sections:<br />

■ “Memory Types” on page 2–1<br />

■ “Memory Features” on page 2–2<br />

■ “Memory Modes” on page 2–3<br />

■ “Mixed-Width Port Configurations” on page 2–4<br />

■ “Clocking Modes” on page 2–5<br />

■ “Parity Bit” on page 2–6<br />

■ “Byte Enable” on page 2–6<br />

■ “Design Considerations” on page 2–8<br />

The <strong>Arria</strong> V devices contain two types of memory blocks:<br />

■ M10K blocks—10-kilobit (Kb) blocks of dedicated memory resources that you can<br />

use to create designs with large memory configurations.<br />

■ Memory logic array blocks (MLABs)—640-bit enhanced memory blocks that are<br />

configured from dual-purpose logic array blocks (LABs). The MLABs are<br />

optimized for implementation of shift registers for digital signal processing (DSP)<br />

applications, wide shallow FIFO buffers, and filter delay lines. Each MLAB is<br />

made up of ten adaptive logic modules (ALMs) that you can configure as ten<br />

32 x 2 blocks, giving you one 32 x 20 simple dual-port SRAM block per MLAB.<br />

f For information about the embedded memory capacity available in each <strong>Arria</strong> V<br />

device, refer to the <strong>Arria</strong> V <strong>Device</strong> Overview.<br />

ISO<br />

9001:2008<br />

Registered<br />

Feedback Subscribe

2–2 Chapter 2: Memory Blocks in <strong>Arria</strong> V <strong>Device</strong>s<br />

Memory Features<br />

Memory Features<br />

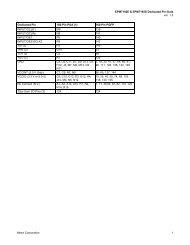

Table 2–1 summarizes the features supported by the memory blocks.<br />

Table 2–1. Memory Features in <strong>Arria</strong> V <strong>Device</strong>s<br />

Feature M10K MLAB<br />

Maximum operating frequency 400 MHz 500 MHz<br />

Total RAM bits (including parity bits) 10,240 640<br />

Configuration (depth × width)<br />

256 x 32, 256 x 40,<br />

512 x 16, 512 x 20,<br />

1K x 8, 1K x 10,<br />

2K x 4, 2K x 5,<br />

4K x 2, and 8K x 1<br />

32 x 16, 32 x 18, and 32 x 20<br />

Parity bits Yes Yes<br />

Byte enable Yes Yes<br />

Packed mode Yes —<br />

Address clock enable Yes Yes<br />

Memory modes<br />

■ Single-port memory<br />

■ Simple dual-port memory<br />

■ True dual-port memory<br />

■ Embedded shift register<br />

■ ROM<br />

■ FIFO buffer<br />

■ Single-port memory<br />

■ Simple dual-port memory<br />

■ Embedded shift register<br />

■ ROM<br />

■ FIFO buffer<br />

Simple dual-port mixed width Yes —<br />

True dual-port mixed width Yes —<br />

FIFO buffer mixed width Yes —<br />

Memory Initialization File (.mif) Yes Yes<br />

Mixed-clock mode Yes Yes<br />

■ Registered output ports—Cleared.<br />

Power-up state Output ports are cleared.<br />

■ Unregistered output ports—Read<br />

memory contents.<br />

Asynchronous clears Output registers<br />

Write/Read operation triggering Rising clock edges<br />

Same-port read-during-write<br />

Mixed-port read-during-write<br />

Output ports set to “new data” or<br />

“don’t care”.<br />

(The “don’t care” mode applies only for<br />

the single-port RAM mode.)<br />

Output ports set to “old data” or “don’t<br />

care”.<br />

Output ports set to “don’t care”.<br />

Output ports set to “old data”, “new<br />

data”, “don’t care”, or “constrained don’t<br />

care”.<br />

ECC support Soft IP support using the Quartus ® II software.<br />

Fully synchronous memory Yes Yes<br />

Asynchronous memory —<br />

Only for flow-through read memory<br />

operations.<br />

<strong>Arria</strong> V <strong>Device</strong> <strong>Handbook</strong> June 2012 <strong>Altera</strong> Corporation<br />

Volume 1: <strong>Device</strong> Interfaces and Integration

Chapter 2: Memory Blocks in <strong>Arria</strong> V <strong>Device</strong>s 2–3<br />

Memory Modes<br />

Memory Modes<br />

Table 2–2 lists and describes the memory modes that are supported in the <strong>Arria</strong> V<br />

memory blocks.<br />

c To avoid corrupting the memory contents, do not violate the setup or hold time on<br />

any of the memory block input registers during read or write operations. This is<br />

applicable if you use the memory blocks in single-port RAM, simple dual-port RAM,<br />

true dual-port RAM, or ROM mode.<br />

Table 2–2. Memory Modes Supported in the Memory Blocks<br />

Memory Mode Description and Additional Information<br />

Single-port RAM<br />

Simple dual-port<br />

RAM<br />

True dual-port RAM<br />

Shift-register<br />

ROM<br />

FIFO<br />

You can perform only one read or one write operation at a time.<br />

Use the read enable port to control the RAM output ports behavior during a write operation:<br />

■ To retain the previous values that are held during the most recent active read enable—Create a<br />

read-enable port and perform the write operation with the read enable port deasserted.<br />

■ To show the new data being written, the old data at that address, or a “Don't Care” value when<br />

read-during-write occurs at the same address location—Do not create a read-enable signal, or<br />

activate the read enable during a write operation.<br />

You can simultaneously perform one read and one write operations to different locations where the<br />

write operation happens on port A and the read operation happens on port B.<br />

You can perform any combination of two port operations: two reads, two writes, or one read and<br />

one write at two different clock frequencies. This mode is available only for M10K blocks.<br />

You can use the memory blocks as a shift-register block to save logic cells and routing resources.<br />

This is useful in DSP applications that require local data storage such as finite impulse response<br />

(FIR) filters, pseudo-random number generators, multi-channel filtering, and auto- and crosscorrelation<br />

functions. Traditionally, the local data storage is implemented with standard flip-flops<br />

that exhaust many logic cells for large shift registers.<br />

You can use the memory blocks as ROM.<br />

■ Initialize the ROM contents of the memory blocks using a .mif or .hex.<br />

■ The address lines of the ROM are registered on M10K blocks but can be unregistered on MLABs.<br />

■ The outputs can be registered or unregistered.<br />