Here - the ESAFORM 2008 Conference - INSA de Lyon

Here - the ESAFORM 2008 Conference - INSA de Lyon

Here - the ESAFORM 2008 Conference - INSA de Lyon

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

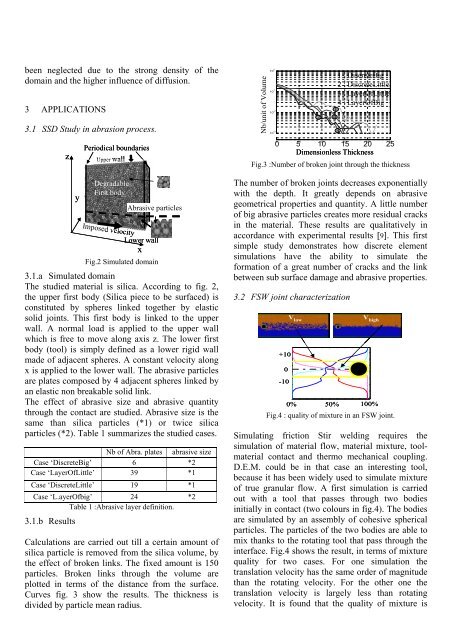

een neglected due to <strong>the</strong> strong <strong>de</strong>nsity of <strong>the</strong>domain and <strong>the</strong> higher influence of diffusion.3 APPLICATIONS3.1 SSD Study in abrasion process.zyPeriodical boundariesUpper wallDegradableFirst bodyImposed velocityAbrasive particlesLower wallxFig.2 Simulated domain3.1.a Simulated domainThe studied material is silica. According to fig. 2,<strong>the</strong> upper first body (Silica piece to be surfaced) isconstituted by spheres linked toge<strong>the</strong>r by elasticsolid joints. This first body is linked to <strong>the</strong> upperwall. A normal load is applied to <strong>the</strong> upper wallwhich is free to move along axis z. The lower firstbody (tool) is simply <strong>de</strong>fined as a lower rigid wallma<strong>de</strong> of adjacent spheres. A constant velocity alongx is applied to <strong>the</strong> lower wall. The abrasive particlesare plates composed by 4 adjacent spheres linked byan elastic non breakable solid link.The effect of abrasive size and abrasive quantitythrough <strong>the</strong> contact are studied. Abrasive size is <strong>the</strong>same than silica particles (*1) or twice silicaparticles (*2). Table 1 summarizes <strong>the</strong> studied cases.Nb of Abra. plates abrasive sizeCase ‘DiscreteBig’ 6 *2Case ‘LayerOfLittle’ 39 *1Case ‘DiscreteLittle’ 19 *1Case ‘L.ayerOfbig’ 24 *2Table 1 :Abrasive layer <strong>de</strong>finition.3.1.b ResultsCalculations are carried out till a certain amount ofsilica particle is removed from <strong>the</strong> silica volume, by<strong>the</strong> effect of broken links. The fixed amount is 150particles. Broken links through <strong>the</strong> volume areplotted in terms of <strong>the</strong> distance from <strong>the</strong> surface.Curves fig. 3 show <strong>the</strong> results. The thickness isdivi<strong>de</strong>d by particle mean radius.Nb/unit of Volume10 010 -110 -210 -31 : DiscreteBig2 : DiscreteLittle3 : LayerOfLittle4 : LayerOfBig12 45 0 10 5 15 10 20 15 25 20 3025Dimensionless ThicknessFig.3 :Number of broken joint through <strong>the</strong> thicknessThe number of broken joints <strong>de</strong>creases exponentiallywith <strong>the</strong> <strong>de</strong>pth. It greatly <strong>de</strong>pends on abrasivegeometrical properties and quantity. A little numberof big abrasive particles creates more residual cracksin <strong>the</strong> material. These results are qualitatively inaccordance with experimental results [9]. This firstsimple study <strong>de</strong>monstrates how discrete elementsimulations have <strong>the</strong> ability to simulate <strong>the</strong>formation of a great number of cracks and <strong>the</strong> linkbetween sub surface damage and abrasive properties.33.2 FSW joint characterization50+100454035-10V low302520150 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1V high0% 50%100%Fig.4 : quality of mixture in an FSW joint.Simulating friction Stir welding requires <strong>the</strong>simulation of material flow, material mixture, toolmaterialcontact and <strong>the</strong>rmo mechanical coupling.D.E.M. could be in that case an interesting tool,because it has been wi<strong>de</strong>ly used to simulate mixtureof true granular flow. A first simulation is carriedout with a tool that passes through two bodiesinitially in contact (two colours in fig.4). The bodiesare simulated by an assembly of cohesive sphericalparticles. The particles of <strong>the</strong> two bodies are able tomix thanks to <strong>the</strong> rotating tool that pass through <strong>the</strong>interface. Fig.4 shows <strong>the</strong> result, in terms of mixturequality for two cases. For one simulation <strong>the</strong>translation velocity has <strong>the</strong> same or<strong>de</strong>r of magnitu<strong>de</strong>than <strong>the</strong> rotating velocity. For <strong>the</strong> o<strong>the</strong>r one <strong>the</strong>translation velocity is largely less than rotatingvelocity. It is found that <strong>the</strong> quality of mixture is