Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

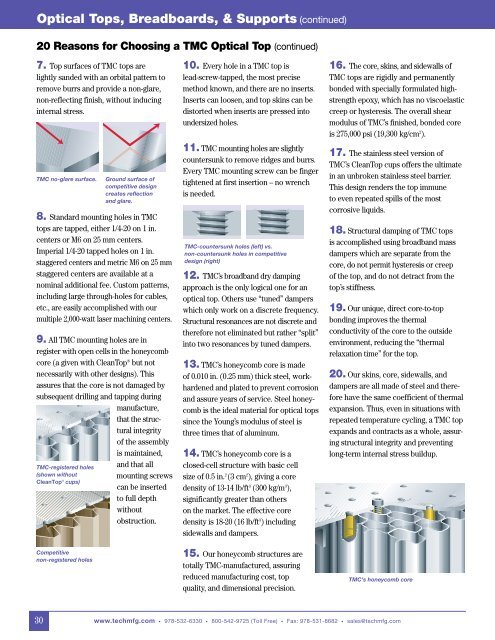

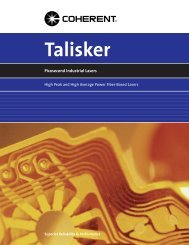

Optical Tops, Breadboards, & Supports (continued)20 Reasons for Choosing a <strong>TMC</strong> Optical Top (continued)7. Top surfaces of <strong>TMC</strong> tops arelightly sanded with an orbital pattern toremove burrs and provide a non-glare,non-reflecting finish, without inducinginternal stress.<strong>TMC</strong> no-glare surface.8. Standard mounting holes in <strong>TMC</strong>tops are tapped, either 1/4-20 on 1 in.centers or M6 on 25 mm centers.Imperial 1/4-20 tapped holes on 1 in.staggered centers and metric M6 on 25 mmstaggered centers are available at anominal additional fee. Custom patterns,including large through-holes for cables,etc., are easily accomplished with ourmultiple 2,000-watt laser machining centers.9. All <strong>TMC</strong> mounting holes are inregister with open cells in the honeycombcore (a given with CleanTop ® but notnecessarily with other designs). Thisassures that the core is not damaged bysub sequent drilling and tapping duringmanufacture,that the struc -tural integrityof the assemblyis maintained,<strong>TMC</strong>-registered holes(shown withoutCleanTop ® cups)Competitivenon-registered holesGround surface ofcompetitive designcreates reflectionand glare.and that allmounting screwscan be insertedto full depthwithoutobstruction.10. Every hole in a <strong>TMC</strong> top islead-screw-tapped, the most precisemethod known, and there are no inserts.Inserts can loosen, and top skins can bedistorted when inserts are pressed intoundersized holes.11. <strong>TMC</strong> mounting holes are slightlycountersunk to remove ridges and burrs.Every <strong>TMC</strong> mounting screw can be fingertightened at first insertion – no wrenchis needed.<strong>TMC</strong>-countersunk holes (left) vs.non-countersunk holes in competitivedesign (right)12. <strong>TMC</strong>’s broadband dry dampingapproach is the only logical one for anoptical top. Others use “tuned” damperswhich only work on a discrete frequency.Structural resonances are not discrete andtherefore not eliminated but rather “split”into two resonances by tuned dampers.13. <strong>TMC</strong>’s honeycomb core is madeof 0.010 in. (0.25 mm) thick steel, workhardenedand plated to prevent corrosionand assure years of service. Steel honeycombis the ideal material for optical topssince the Young’s modulus of steel isthree times that of aluminum.14. <strong>TMC</strong>’s honeycomb core is aclosed-cell structure with basic cellsize of 0.5 in. 2 (3 cm 2 ), giving a coredensity of 13-14 lb/ft 3 (300 kg/m 3 ),significantly greater than otherson the market. The effective coredensity is 18-20 (16 lb/ft 3 ) includingsidewalls and dampers.15. Our honeycomb structures aretotally <strong>TMC</strong>-manufactured, assuringreduced manufacturing cost, topquality, and dimensional precision.16. The core, skins, and sidewalls of<strong>TMC</strong> tops are rigidly and permanentlybonded with specially formulated highstrengthepoxy, which has no viscoelasticcreep or hysteresis. The overall shearmodulus of <strong>TMC</strong>’s finished, bonded coreis 275,000 psi (19,300 kg/cm 2 ).17. The stainless steel version of<strong>TMC</strong>’s CleanTop cups offers the ultimatein an unbroken stainless steel barrier.This design renders the top immuneto even repeated spills of the mostcorrosive liquids.18. Structural damping of <strong>TMC</strong> topsis accomplished using broadband massdampers which are separate from thecore, do not permit hysteresis or creepof the top, and do not detract from thetop’s stiffness.19. Our unique, direct core-to-topbonding improves the thermalconductivity of the core to the outsideenvironment, reducing the “thermalrelaxation time” for the top.20. Our skins, core, sidewalls, anddampers are all made of steel and thereforehave the same coefficient of thermalexpansion. Thus, even in situations withrepeated temperature cycling, a <strong>TMC</strong> topexpands and contracts as a whole, assuringstructural integrity and preventinglong-term internal stress buildup.<strong>TMC</strong>’s honeycomb core30 www.techmfg.com • 978-532-6330 • 800-542-9725 (Toll Free) • Fax: 978-531-8682 • sales@techmfg.com