stories on hard material matters - Ceratizit S.A.

stories on hard material matters - Ceratizit S.A.

stories on hard material matters - Ceratizit S.A.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

18<br />

ÅKERS, SWEDEN<br />

Roll machining with<br />

CERATIZIT tooling<br />

Customer report from the Åkers roll foundry in Sweden.<br />

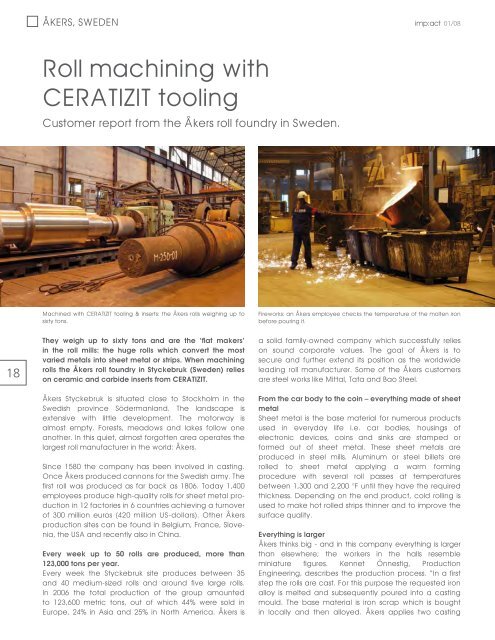

Machined with CERATIZIT tooling & inserts: the Åkers rolls weighing up to<br />

sixty t<strong>on</strong>s.<br />

They weigh up to sixty t<strong>on</strong>s and are the ‘flat makers’<br />

in the roll mills: the huge rolls which c<strong>on</strong>vert the most<br />

varied metals into sheet metal or strips. When machining<br />

rolls the Åkers roll foundry in Styckebruk (Sweden) relies<br />

<strong>on</strong> ceramic and carbide inserts from CERATIZIT.<br />

Åkers Styckebruk is situated close to Stockholm in the<br />

Swedish province Södermanland. The landscape is<br />

extensive with little development. The motorway is<br />

almost empty. Forests, meadows and lakes follow <strong>on</strong>e<br />

another. In this quiet, almost forgotten area operates the<br />

largest roll manufacturer in the world: Åkers.<br />

Since 1580 the company has been involved in casting.<br />

Once Åkers produced cann<strong>on</strong>s for the Swedish army. The<br />

first roll was produced as far back as 1806. Today 1,400<br />

employees produce high-quality rolls for sheet metal producti<strong>on</strong><br />

in 12 factories in 6 countries achieving a turnover<br />

of 300 milli<strong>on</strong> euros (420 milli<strong>on</strong> US-dollars). Other Åkers<br />

producti<strong>on</strong> sites can be found in Belgium, France, Slovenia,<br />

the USA and recently also in China.<br />

Every week up to 50 rolls are produced, more than<br />

123,000 t<strong>on</strong>s per year.<br />

Every week the Styckebruk site produces between 35<br />

and 40 medium-sized rolls and around five large rolls.<br />

In 2006 the total producti<strong>on</strong> of the group amounted<br />

to 123,600 metric t<strong>on</strong>s, out of which 44% were sold in<br />

Europe, 24% in Asia and 25% in North America. Åkers is<br />

imp:act 01/08<br />

Fireworks: an Åkers employee checks the temperature of the molten ir<strong>on</strong><br />

before pouring it.<br />

a solid family-owned company which successfully relies<br />

<strong>on</strong> sound corporate values. The goal of Åkers is to<br />

secure and further extend its positi<strong>on</strong> as the worldwide<br />

leading roll manufacturer. Some of the Åkers customers<br />

are steel works like Mittal, Tata and Bao Steel.<br />

From the car body to the coin – everything made of sheet<br />

metal<br />

Sheet metal is the base <strong>material</strong> for numerous products<br />

used in everyday life i.e. car bodies, housings of<br />

electr<strong>on</strong>ic devices, coins and sinks are stamped or<br />

formed out of sheet metal. These sheet metals are<br />

produced in steel mills. Aluminum or steel billets are<br />

rolled to sheet metal applying a warm forming<br />

procedure with several roll passes at temperatures<br />

between 1,300 and 2,200 °F until they have the required<br />

thickness. Depending <strong>on</strong> the end product, cold rolling is<br />

used to make hot rolled strips thinner and to improve the<br />

surface quality.<br />

Everything is larger<br />

Åkers thinks big - and in this company everything is larger<br />

than elsewhere; the workers in the halls resemble<br />

miniature figures. Kennet Önnestig, Producti<strong>on</strong><br />

Engineering, describes the producti<strong>on</strong> process. “In a first<br />

step the rolls are cast. For this purpose the requested ir<strong>on</strong><br />

alloy is melted and subsequently poured into a casting<br />

mould. The base <strong>material</strong> is ir<strong>on</strong> scrap which is bought<br />

in locally and then alloyed. Åkers applies two casting