stories on hard material matters - Ceratizit S.A.

stories on hard material matters - Ceratizit S.A.

stories on hard material matters - Ceratizit S.A.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

36<br />

AUSTRIA ALU-GUSS<br />

The individual hallmark of the car<br />

In the field of rim producti<strong>on</strong> Austria Alu-Guss relies <strong>on</strong> OvalFlex<br />

from CERATIZIT.<br />

Its design is the eye-catching feature of a car, providing<br />

it with a pers<strong>on</strong>al touch: the aluminum rim. It is en vogue<br />

as never before, and almost every automobile today<br />

has aluminum rims as a standard feature. The variety of<br />

types and design is c<strong>on</strong>tinuously increasing. OvalFlex,<br />

a modular turning tool developed by CERATIZIT, fulfils<br />

the demands of the manufacturers regarding flexibility,<br />

productivity and process security. The CERATIZIT<br />

customer Austria Alu-Guss, who is <strong>on</strong>e of the big players<br />

in the sector (producti<strong>on</strong> volume of three milli<strong>on</strong><br />

aluminum wheels per year) has successfully applied<br />

OvalFlex since the beginning of 2007.<br />

The tendency: exclusive styling<br />

Light metal wheels are applied in formula 1 cars, trucks<br />

for heavy load transports and also in the aerospace<br />

industry. The major share however are aluminum wheels<br />

for automobiles where basically two types may be<br />

distinguished: <strong>on</strong>e-piece rims in <strong>on</strong>e casting and multi-<br />

piece rims which are c<strong>on</strong>nected by screws and c<strong>on</strong>sist of<br />

a rim bed, a rim crown and a centre hub.<br />

Austria Alu-Guss is based in the Austrian Ranshofen,<br />

has been a member of the Borbet group since 1996<br />

and develops and produces aluminum rims for Audi,<br />

BMW, Mercedes, Opel, GM, Porsche, VW, Seat etc. The<br />

company has 730 employees and offers wheel types with<br />

annual quantities over 100,000 pieces as well as small<br />

batches of less than 1,000 pieces. The trend is towards<br />

smaller batch sizes whereas the styling is becoming<br />

increasingly varied. “The most important task is to<br />

technically implement the customer’s wishes regarding<br />

the design,” says Alois Grömer from the mechanical<br />

machining department at Austria Alu-Guss. “A light<br />

metal wheel almost always represents a compromise.”<br />

Stability and high performance: OvalFlex<br />

On a c<strong>on</strong>veyor belt the blank aluminum rim is transported<br />

to the CNC machine, where it is turned at around<br />

2,000 rev/min applying OvalFlex.<br />

OvalFlex has exclusively been developed for machining<br />

light metal wheels. The oval shape differs from the<br />

c<strong>on</strong>venti<strong>on</strong>al round shape of copy turning tools. In this<br />

way the tool does not need so much space and can go<br />

deeper into the rim. The height however has remained<br />

the same and guarantees stability which increases<br />

profitability, as high stability makes larger depths of cut<br />

possible.<br />

imp:act 01/08<br />

The main attracti<strong>on</strong>: the new oval interface c<strong>on</strong>nects<br />

the tool shank with the tool head. Four tapered surfaces<br />

around the interface provide accurate c<strong>on</strong>necti<strong>on</strong><br />

with the locati<strong>on</strong> face in both radial and axial directi<strong>on</strong>.<br />

Thanks to this highly precise c<strong>on</strong>necti<strong>on</strong> it is almost<br />

unnecessary to make correcti<strong>on</strong>s.<br />

High flexibility, reduced logistics<br />

Another advantage of OvalFlex is its modularity.<br />

Different styles of tool heads can be mounted <strong>on</strong> the<br />

adapters. In additi<strong>on</strong>, different angles can be set <strong>on</strong><br />

the tools. A system which ensures that aluminum wheel<br />

manufacturers benefit commercially and logistically, as<br />

thanks to modularity they need fewer special tools and<br />

the necessity for stock keeping is decreased.<br />

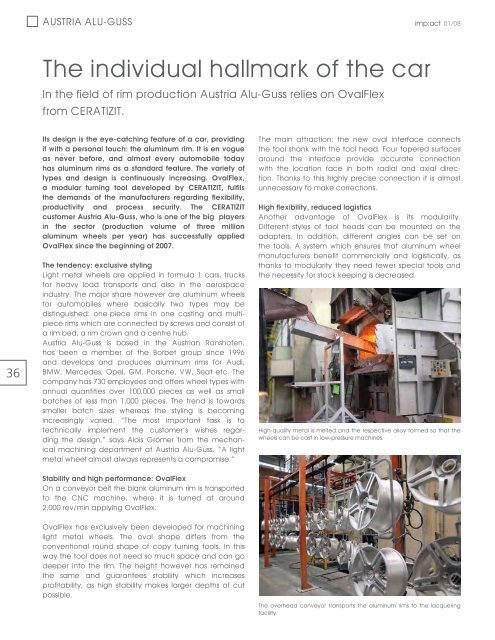

High-quality metal is melted and the respective alloy formed so that the<br />

wheels can be cast in low-pressure machines.<br />

The overhead c<strong>on</strong>veyor transports the aluminum rims to the lacquering<br />

facility.