Chemical Analysis of Value Added Dairy Products and Their Quality ...

Chemical Analysis of Value Added Dairy Products and Their Quality ...

Chemical Analysis of Value Added Dairy Products and Their Quality ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Dr. Rajan SharmaSenior Scientist & Director, Winter SchoolDr. (Mrs.) Bimlesh MannPrincipal Scientist & Co-Director, Winter SchoolCourse AdvisorsDr. (Mrs.) B.K. WadhwaDr. Darshan LalDr. Raman SethALL RIGHTS RESERVEDNo part <strong>of</strong> the lecture compendium may be reproduced or transmitted in any form or byany means, electronic or mechanical, including photocopy, recording, or any information,storage <strong>and</strong> retrieval system without the written permission <strong>of</strong> Director, NDRI, Karnal.

Committees for Organisation <strong>of</strong> Winter SchoolOrganizing CommitteeDr. (Mrs.) B.K. Wadhwa, Head & Principal ScientistDr. Darshan Lal, Principal ScientistDr. Raman Seth, Principal ScientistDr. (Mrs) Bimlesh Mann, Principal ScientistDr. Sumit Arora, Senior ScientistDr. Vivek Sharma, Senior ScientistDr. Rajesh Kumar, Senior ScientistDr. Rajan Sharma, Senior Scientist (Convener)Registration CommitteeDr. Raman Seth (Chairman)Dr. Rajesh Kumar (Convener)Dr. Sumit AroraSh. P.C. SinghSh. Ajit SinghTechnical ComiitteeDr. Darshan Lal (Chairman)Dr. (Mrs) Bimlesh Mann (Convener)Dr. Raman SethDr. Rajesh KumarDr. Rajan SharmaHospitality CommitteeDr. (Mrs.) B.K. Wadhwa (Chairman)Dr. Vivek Sharma (Convener)Dr. (Mrs.) Bimlesh MannSh. Rajeev SharmaPurchase CommitteeDr. (Mrs) Bimlesh Mann (Chairman)Dr. Rajan Sharma (Convener)Dr. Rajesh KumarDr. Vivek Sharma

THEORYContents1. Novel <strong>and</strong> Emerging Food Technologies for Defence Food Supplies 1A. S. Bawa2. An Overview <strong>of</strong> Designer Functional <strong>and</strong> Health Foods5A. K. Srivastava3. Prospects <strong>of</strong> <strong>Value</strong> Addition Through Functional Ingredients 10G. R. Patil4. Technological <strong>and</strong> Nutritional Aspects <strong>of</strong> Milk Phospholipids 17B. K. Wadhwa <strong>and</strong> Rajesh Kumar5.Methods <strong>of</strong> Cholesterol Removal to Develop Low –Cholesterol <strong>Dairy</strong> <strong>Products</strong> 22Darshan Lal <strong>and</strong> Vivek Sharma6. Fortification <strong>of</strong> Milk <strong>and</strong> Milk <strong>Products</strong> for <strong>Value</strong> Addition 29Sumit Arora7. Packaging <strong>of</strong> <strong>Value</strong> <strong>Added</strong> Foods <strong>and</strong> <strong>Their</strong> Storage Stability 36P. P. Gothwal8.Novel Technologies for Processing <strong>and</strong> Packaging <strong>of</strong>Health Foods <strong>and</strong> Beverages 40H. N. Mishra9. Glycomacropeptide – Biological Properties <strong>and</strong> its Application 49Rajan Sharma <strong>and</strong> Neelima Sharma10.11.New Approaches to Detect the Adulteration <strong>of</strong> Gheewith Animal Body Fats <strong>and</strong> Vegetable Oils/ Fats 54Vivek Sharma, Darshan Lal, Arun Kumar <strong>and</strong> Amit KumarColostrum Powder <strong>and</strong> its HealthBenefits 59Raman Seth <strong>and</strong> Anamika Das12. Cow Ghee Protects from Mammary Carcinogenesis: Mechanism 68Vinod K. Kansal, Rita Rani <strong>and</strong> Ekta Bhatia13.Lateral Flow Assay- Principle <strong>and</strong> its Application inAnalytical Food Science 72Rajan Sharma <strong>and</strong> Priyanka Singh Rao14. Separation Strategies for Bioactive Milk Proteins 77Rajesh Kumar15. SDS-PAGE – Principle <strong>and</strong> Applications 81Y. S. Rajput <strong>and</strong> Rajan SharmaWestern Blot: Theoretical Aspects 816. 5Y. S. Rajput <strong>and</strong> Rajan Sharma

17. Enzyme Linked Immunosorbent Assay - Theory 88Rajeev Kapila <strong>and</strong> Suman Kapila18.19.Experimental Determination <strong>of</strong> Thermal Stability <strong>of</strong>Proteins: A Theoretical Background 93Jai K. KaushikSpecies-Specific Identification <strong>of</strong> Milk <strong>and</strong> Milk<strong>Products</strong>: A Molecular Approach 97Archana Verma20. Proteomic Techniques for Application in Food Science 100Ashok K. Mohanty21.Evaluation <strong>of</strong> Probiotic Attributes <strong>of</strong> <strong>Dairy</strong> StarterCultures Using Various Test Methods 106Rameshwar Singh22. Identification <strong>of</strong> Lactobacillus spp by PCR based MolecularMethodology 110Sachin<strong>and</strong>an De <strong>and</strong> Rupinder Kaur23.24.25.Antimicrobial Substances produced by LacticAcid Bacteria (LAB) 114Shilpa Vij, Subrota Hati <strong>and</strong> Minakshi DahiyaMicrobiological Risk Assessment: A NewConcept to Ensure Food Safety 117Naresh Kumar <strong>and</strong> Raghu H. V.Biopreservation <strong>of</strong> <strong>Dairy</strong> <strong>Products</strong>: Role <strong>of</strong> Bacteriocins<strong>of</strong> Lactic Acid Bacteria 126R. K. Malik <strong>and</strong> Gurpreet Kaur26. Regulatory Aspects <strong>of</strong> Functional Foods 135Bimlesh mann , Rajesh Kumar <strong>and</strong> Prerna Saini27.28.29.30.31.Nanomaterials - <strong>Their</strong> Applications <strong>and</strong> SafetyAspects in Foods 142Bimlesh Mann , Rajesh Kumar <strong>and</strong> Prabhakar PadghamStrategies for Animals Studies to Assess theSafety Aspects <strong>and</strong> Bioavailability <strong>of</strong> Netraceuticals 145Ayyasamy Manimaran <strong>and</strong> Bimlesh MannRecent Advances in Synbiotic <strong>Dairy</strong> Foods <strong>and</strong><strong>Their</strong> Safety Evaluation 151Ch<strong>and</strong> Ram, Manju <strong>and</strong> Santosh An<strong>and</strong>Physical Characterization <strong>of</strong> <strong>Dairy</strong> Foods withReference to Viscosity, Colour <strong>and</strong> Water Activity 160R. R. B. Singh <strong>and</strong> Prateek SharmaMalt Based Milk Foods as “<strong>Value</strong> <strong>Added</strong>Functional <strong>Dairy</strong> <strong>Products</strong>” 165Laxmana Naik, Rajan Sharma, Manju G. <strong>and</strong> Amit K. Barui

32.PRACTICALPreparation <strong>and</strong> Characterization <strong>of</strong> Gold Nanoparticles,<strong>Their</strong> Conjugation with Antibodies <strong>and</strong> Construction<strong>of</strong> Lateral Flow Devices 170Priyanka Singh Rao, Swapnil Sonar, Y.S. Rajput <strong>and</strong> Rajan Sharma33. Use <strong>of</strong> Lateral Flow Technique for Detecting Melamine in Milk 173Raman Seth <strong>and</strong> Anamika Dass34.35.Rancimat (Accelerated <strong>and</strong> Automated) Method forEvaluation <strong>of</strong> Oxidative Stability <strong>of</strong> Fats <strong>and</strong> Oils 177Sumit AroraEstimation <strong>of</strong> Cholesterol Content in Ghee Using aCholesterol Estimation Kit 182Vivek Sharma <strong>and</strong> Darshan Lal36. Rapid Methods for Detection <strong>of</strong> Adulterants in Milk 184Rajan Sharma, Raman Seth <strong>and</strong> Amit K. Bauri37.38.39.Detection <strong>of</strong> Foreign Fats/Oils in Milk <strong>and</strong> GheeUsing Newer Approaches 189Darshan Lal, Vivek Sharma, Arun Kumar <strong>and</strong> Amit KumarDetermination <strong>of</strong> Total Polyphenolic Content in FruitEnriched <strong>Dairy</strong> Product 195Rajesh Kumar <strong>and</strong> Richa SinghSeparation <strong>and</strong> Identification <strong>of</strong> Low MolecularWeight Proteins Using Tricine SDS-PAGE 197Neelima Sharma, Rajan Sharma <strong>and</strong> Y. S. Rajput40. Identification <strong>of</strong> Proteins Through Western Blotting – Practical 200Neelima Sharma, Amit K.Barui <strong>and</strong> Y.S. Rajput41. Typing <strong>of</strong> Milk for A1 <strong>and</strong> A2 beta Casein 204Sachin<strong>and</strong>an De, C. M. Hari Kishore, Ayan Mukherjee <strong>and</strong> Rupinder Kaur42. Enzyme-Linked Immunosorbent Assay-Practical 206Suman Kapila <strong>and</strong> Rajeev Kapila43. Evaluation <strong>of</strong> Biological Activity <strong>of</strong> Milk Protein Ingredients 208Bimlesh Mann, Prerna Saini, Prabhakar Padghan, Anuradha Kumari44. Purification <strong>of</strong> Bioactive Proteins from Milk 212Neha Mishra, Rajesh Kumar <strong>and</strong> Jai K Kaushik45. Immunological Method to Detect Buffalo Milk in Cow Milk 214Archana Verma46. Conjugated Linoleic Acid <strong>and</strong> Its Estimation 217A. K. Tyagi, A. Hossain, A. Tyagi47.Importance <strong>and</strong> Estimation <strong>of</strong> Vitamins A & Ein <strong>Value</strong> <strong>Added</strong> <strong>Dairy</strong> <strong>Products</strong> 221Harjit Kaur

48.49.50.Use <strong>of</strong> Atomic Absorption Spectrophotometer for theEstimation <strong>of</strong> Minerals in Milk <strong>and</strong> Milk <strong>Products</strong> 225Veena ManiPesticides: <strong>Their</strong> <strong>Analysis</strong> in Milk Using HighPerformance Liquid Chromatography 230Ch<strong>and</strong>er Datt <strong>and</strong> Monica PuniyaEstimation <strong>of</strong> Microbial GOS by High PerformanceLiquid Chromatography 233Vikas Sangwan <strong>and</strong> Sudhir Kumar Tomar51. Estimation <strong>of</strong> Trehalose Production by Propionibacteria 236Poonam <strong>and</strong> Sudhir Kumar Tomar52.53.Spore Based Biosensor as A <strong>Quality</strong> Control Tool in<strong>Dairy</strong> Industry 239Naresh Kumar, Raghu H. V. <strong>and</strong> AvinashDetection <strong>and</strong> Evaluation <strong>of</strong> Antimicrobial Activities <strong>of</strong>Bacteriocins <strong>and</strong> Bioactive Peptides Produced by LAB 248Shilpa Vij, Subrota Hati <strong>and</strong> Meenakshi Dahiy

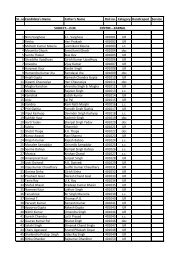

Programme Schedule for Winter SchoolProgramme Schedule for Winter School<strong>Chemical</strong> <strong>Analysis</strong> <strong>of</strong> <strong>Value</strong> <strong>Added</strong> <strong>Dairy</strong> <strong>Products</strong> <strong>and</strong> <strong>Their</strong> <strong>Quality</strong> AssuranceJanuary 11-31, 201111 th January 2011(Tuesday)9.00 AM – 9.30 AM Registration <strong>of</strong> Participants9.30 AM -12.30 PMInauguration <strong>of</strong> Winter SchoolNovel <strong>and</strong> Emerging Food Technologies for Defence Food Supplies – Inagural Lectureby Dr. A.S.Bawa, Director, Defence Food Research Laboratory, Mysore12.30 PM -1.00 PM Visit to ATIC/Institute FilmLunch2.15 PM – 3.15 PM Achievements <strong>of</strong> <strong>Dairy</strong> Chemistry Division Dr. (Mrs.) B.K. Wadhwa3.15 PM – 4.30 PM Prospects <strong>of</strong> <strong>Value</strong> Addition Through functional Ingredients Dr. G.R. Patil12 th January 2011 (Wednesday)9.45 AM -10.45 AM11.00 AM – 12.00 PM12.00 PM – 1.00 PMLunch2.15 PM -5.00 PMMethod <strong>of</strong> Cholesterol Removal to Develop Low Cholesterol<strong>Dairy</strong> <strong>Products</strong> – TheoryFortifi cation <strong>of</strong> Milk <strong>and</strong> Milk <strong>Products</strong> for <strong>Value</strong> Addition –TheoryCow Ghee Protects from Mammary Carcinogenesis:Mechanism – TheoryEstimation <strong>of</strong> Cholesterol Content in Ghee Using aCholesterol Estimation Kit– PracticalDr. Darshan LalDr. Sumit AroraDr.V.K. KansalDr. Vivek Sharma13 th January 2011 (Thursday)9.45 AM -10.45 AMEvaluation <strong>of</strong> Probiotic Attributes <strong>of</strong> <strong>Dairy</strong> Starter Culturesusing Various Test Methods – TheoryDr. Rameshwar Singh11.00 AM – 12.00 PM Separation Strategies for Bioactive Milk Proteins – Theory Dr. Rajesh Kumar12.00 PM – 1.00 PMLunch2.15 PM – 3.15 PM3.15 PM – 5.00 PMNew Approaches to Detect the Adulteration <strong>of</strong> Milk Gheewith Animal Body Fats <strong>and</strong> Vegetable Oils/ Fats – Theory<strong>Quality</strong> <strong>and</strong> Food Safety in Yoghurt Industry – Guest LectureDetection <strong>of</strong> Foreign Fats/Oils in Milk <strong>and</strong> Ghee Using NewerApproaches - PracticalDr. Vivek SharmaMr. Anuj Mehta(Danone India Ltd.)Dr. Darshan Lal14 th January 2011 (Friday)9.45 AM -10.45 AMTechnological <strong>and</strong> Nutritional Aspects <strong>of</strong> Milk Phospholipids -TheoryDr.(Mrs.) B.K. Wadhwa11.00 AM – 12.00 PM Colostrum Powder <strong>and</strong> its Health benefi t - Theory Dr. Raman Seth12.00 PM – 1.00 PMNovel Technologies for Processing <strong>and</strong> Packaging <strong>of</strong> HealthFoods <strong>and</strong> Beverages – Guest LectureDr. H.N. MisraIIT, Kharagpur

<strong>Chemical</strong> <strong>Analysis</strong> <strong>of</strong> <strong>Value</strong> <strong>Added</strong> <strong>Dairy</strong> <strong>Products</strong> <strong>and</strong> <strong>Their</strong> <strong>Quality</strong> AssuranceLunch2.15 PM – 5.00 PM Purifi cation <strong>of</strong> Bioactive Proteins from Milk – Practical Dr. Jai K. Kaushik15 th January 2011 (Saturday)9.45 AM -10.45 AM11.00 AM – 12.00 PM12.00 PM – 1.00 PMLunch2.15 PM – 3.15 PM3.15 PM – 5.15 PMNanomaterials - <strong>Their</strong> Applications <strong>and</strong> Safety Aspects inFood – TheoryRecent Advances in Synbiotic <strong>Dairy</strong> Foods <strong>and</strong> their SafetyEvaluation – TheoryDetermination <strong>of</strong> Total Polyphenolic Content in Fruit Enriched<strong>Dairy</strong> Product– Theory & Practicalcontd…. Determination <strong>of</strong> Total Polyphenolic Content in FruitEnriched <strong>Dairy</strong> Product – PracticalRancimat (Accelerated <strong>and</strong> Automated) Method forEvaluation <strong>of</strong> Oxidative Stability <strong>of</strong> Fats <strong>and</strong> Oils – Theory &PracticalDr. (Mrs.) Bimlesh MannDr. Ch<strong>and</strong> RamDr. Rajesh KumarDr. Rajesh KumarDr. Sumit Arora16 th January 2011(Sunday)17 th January 2011 (Monday)9.45 AM -10.45 AM SDS-PAGE – Principle <strong>and</strong> Applications -Theory Dr. Y.S. Rajput11.00 AM – 1.00 PMLunchSeparation <strong>and</strong> Identifi cation <strong>of</strong> Low Molecular WeightProteins using SDS-PAGE – PracticalDr. Y.S. Rajput2.15 PM – 3.15 PM Western Blot: Theoretical Aspects – Theory Dr. Y.S. Rajput3.15 PM- 5.00 PM Identifi cation <strong>of</strong> Proteins through Western Blotting – Practical Dr. Y.S. Rajput18 th January 2011 (Tuesday)9.45 AM -10.45 AM11.00 AM – 1.00 PMLunch2.15 PM – 3.15 PM3.15 PM - 4.00 PMLateral Flow Assay- Principle <strong>and</strong> its Application in AnalyticalFood Science – TheoryPreparation <strong>and</strong> Characterization <strong>of</strong> Gold Nanoparticles, theirConjugation with Antibodies <strong>and</strong> Construction <strong>of</strong> Lateral FlowDevices – Practicalcontd…. Preparation <strong>and</strong> Characterization <strong>of</strong> GoldNanoparticles, their Conjugation with Antibodies <strong>and</strong>Construction <strong>of</strong> Lateral Flow Devices - PracticalUse <strong>of</strong> Lateral Flow Technique for Detecting Melamine inMilk – PracticalDr. Rajan SharmaDr. Rajan SharmaDr. Rajan SharmaDr. Raman Seth4.00 PM – 5.00 PM Regulatory Aspects <strong>of</strong> Functional Foods Dr. Bimlesh Mann19 th January 2011 (Wednesday)9.45 AM -10.45 AM11.00 AM – 1.00 PMLunchImportance <strong>and</strong> Estimation <strong>of</strong> Vitamin A & E in <strong>Value</strong> <strong>Added</strong><strong>Dairy</strong> <strong>Products</strong> – Theorycontd…. Importance <strong>and</strong> estimation <strong>of</strong> vitamin A & E in <strong>Value</strong><strong>Added</strong> <strong>Dairy</strong> <strong>Products</strong> – PracticalDr. (Mrs.) Harjeet KaurDr. (Mrs.) Harjeet Kaur

Programme Schedule for Winter School2.15 PM – 3.30 PM3.30 PM – 5.00 PMEstimation <strong>of</strong> Microbial GOS by HPLC - Theory <strong>and</strong> PracticalEstimation <strong>of</strong> Trehalose Production by Propionibacteria –Theory <strong>and</strong> PracticalDr. S.K. TomarDr. S.K. Tomar20 th January 2011 (Thursday)9.45 AM -10.45 AM11.00 AM – 1.00 PMLunchMicrobiological Risk Assessment: A New Concept to EnsureFood Safety – TheorySpore Based Biosensor as A <strong>Quality</strong> Control Tool in <strong>Dairy</strong>Industry – PracticalDr. Naresh KumarDr. Naresh Kumar2.15 PM – 3.15 PM Enzyme Linked Immunossorbent Assay –Theory Dr. Rajeev Kapila3.15 PM – 5.00 PM Enzyme Linked Immunossorbent Assay – Practical Dr. Suman Kapila21 st January 2011 (Friday)9.45 AM -10.45 AM11.00 AM- 12.00 PMExperimental Determination <strong>of</strong> Thermal Stability <strong>of</strong> Proteins: ATheoretical BackgroundBiopreservation <strong>of</strong> <strong>Dairy</strong> <strong>Products</strong>: Role <strong>of</strong> Bacteriocins <strong>of</strong>Lactic Acid Bacteria – TheoryDr. Jai K KaushikDr. R.K. Malik11.00 AM- 1.00 PM Glycomacropeptide – Biological Properties <strong>and</strong> its Application Dr. Rajan SharmaLunch2.15 PM – 3.15 PM3.15 PM – 5.00 PMPesticides: <strong>Their</strong> <strong>Analysis</strong> in Milk Using High PerformanceLiquid Chromatography– TheoryContd…. Pesticides: <strong>Their</strong> <strong>Analysis</strong> in Milk Using HighPerformance Liquid Chromatography – PracticalDr. Ch<strong>and</strong>er DattDr. Ch<strong>and</strong>er Datt22 nd January 2011(Saturday)Exposure <strong>of</strong> Participants <strong>of</strong> Winter School to “Brain Storming Session on Promotion <strong>of</strong> Indigenous <strong>Dairy</strong> <strong>Products</strong> inInternational Market” being organized by Alumni Association, NDRI, Karnal23 rd January 2011 (Sunday)24 th January 2011(Monday)2.15 PM – 3.30 PMIdentifi cation <strong>of</strong> Lactobacillus spp by PCR based MolecularMethodology – Theory & PracticalDr. Sachin<strong>and</strong>an De3.30 PM – 5.00 PM Typing <strong>of</strong> Milk for A1 <strong>and</strong> A2 beta casein - Theory & Practical Dr. Sachin<strong>and</strong>an DeLunch2.15 PM – 3.15 PM3.15 PM- 5.00 PM9.45 AM -12.00 PM12.00 AM – 1.00 PMLunchUse <strong>of</strong> Atomic Absorption Spectrophotometer for theEstimation <strong>of</strong> Minerals in Milk <strong>and</strong> Milk <strong>Products</strong> – TheoryContd…. Use <strong>of</strong> Atomic Absorption Spectrophotometer for theEstimation <strong>of</strong> Minerals in Milk <strong>and</strong> Milk <strong>Products</strong> – Practical25th January 2011(Tuesday)Physical Characterization <strong>of</strong> <strong>Dairy</strong> Foods with Reference toViscosity, Colour <strong>and</strong> Water Activity – Theory & PracticalAllergen Mangement in Foods - Emerging TrendsDr. (Mrs.) Veena ManiDr. (Mrs.) Veena ManiDr. R.R. B. SinghRajesh Kumar Sharma(Cadbury India Ltd.)

<strong>Chemical</strong> <strong>Analysis</strong> <strong>of</strong> <strong>Value</strong> <strong>Added</strong> <strong>Dairy</strong> <strong>Products</strong> <strong>and</strong> <strong>Their</strong> <strong>Quality</strong> Assurance2.15 PM – 3.15 PM3.15 PM- 5.00 PMCommon Statistical Techniques for Analytical <strong>Dairy</strong> <strong>and</strong> FoodScience – Theorycontd…. Common Statistical Techniques for Analytical <strong>Dairy</strong><strong>and</strong> Food Science – PracticalDr. A.P. RuhilDr. A.P. Ruhil26 th January 2011(Wednesday) – Republic Day27 th January 2011 (Thursday)9.45 AM -10.45 AMStrategies for Animals Studies to Assess the Safety Aspects<strong>and</strong> Bioavailability <strong>of</strong> Netraceuticals – TheoryDr. AyyasamyManimaran11.00 AM – 12.00 PM Rapid Methods for Detection <strong>of</strong> Adulterants in Milk – Practical Dr. Rajan Sharma12.00 PM – 1.00 PM Visit to Model <strong>Dairy</strong> Mr. G. MutrejaLunch2.15 PM – 3.15 PM3.15 PM- 5.00 PMImmunological Method to Detect Buffalo Milk in Cow Milk –PracticalSpecies-Specifi c Identifi cation <strong>of</strong> Milk <strong>and</strong> Milk <strong>Products</strong>: AMolecular Approach - TheoryDr. (Mrs.) ArchanaVermaDr. (Mrs.) Archna Verma28 th January 2011 (Friday)9.45 AM -10.45 AM11.00 AM – 12.00 PMPackaging <strong>of</strong> <strong>Value</strong> <strong>Added</strong> Foods <strong>and</strong> <strong>Their</strong> Storage Stability– Guest LectureFood Additives <strong>and</strong> <strong>Quality</strong> Issues – Guest LectureP.P. Gothwal (CFTRI,Regional Center,Lucknow)Ravinder Kumar(Danisco India Ltd.)12.00 PM – 1.00 PM Proteomic Techniques for Application in Food Science Dr. Ashok K. MohantyLunch2.15 PM – 3.15 PMEvaluation <strong>of</strong> Biological Activity <strong>of</strong> Milk Protein Ingredients –TheoryDr. (Mrs.) Bimlesh Mann3.15 PM – 5.00 PMcontd…. Evaluation <strong>of</strong> Biological Activity <strong>of</strong> Milk ProteinIngredients – PracticalDr. (Mrs.) Bimlesh Mann29 th January 2011 (Saturday)9.45 AM -10.45 AMAntimicrobial Substances Produced by Lactic Acid Bacteria(LAB) - TheoryDr. (Mrs.) Shilpa Vij11.00 AM – 1.00 PMDetection <strong>and</strong> Evaluation <strong>of</strong> Antimicrobial Activities <strong>of</strong>Bacteriocins <strong>and</strong> Bioactive Peptides Produced by LAB – Dr. (Mrs.) Shilpa VijTheory & PracticalLunch2.15 PM – 3.15 PM Conjugated Linoleic Acid <strong>and</strong> Its Estimation – Theory Dr. Amrish TyagiContd…. Conjugated Linoleic Acid <strong>and</strong> Its Estimation –3.15 PM- 5.00 PMPractical30 th January 2011 (Sunday)31 st January 2011(Monday)9.45 AM -10.45 AMCourse EvaluationDr. Amrish TyagiDr. (Mrs.) Bimlesh Mann<strong>and</strong> Dr. Rajan Sharma10.45 AM – 1.00 PMLunchInteraction with FacultyChaired by Head, DCDivision

Novel <strong>and</strong> Emerging Food Technologies for Defence Food SuppliesNovel <strong>and</strong> Emerging Food Technologiesfor Defence Food SuppliesDr. A. S. BawaDirectorDefence Food Research Laboratory, MysoreThe Defence Food Research Laboratory (DFRL) was established in December, 1961 under theaegis <strong>of</strong> Defence Research & Development Organisation (DRDO), Ministry <strong>of</strong> Defence to cater to thestrategic operational requirements <strong>of</strong> our Services <strong>and</strong> to provide logistical support to the Armedforces in the area <strong>of</strong> food supplies. Our troops <strong>of</strong>ten operate in far flung in hospitable treacherousterrains under inclement <strong>and</strong> hostile weather conditions. In such operational situations, not only arethey deprived <strong>of</strong> the fresh produce needed to sustain life processes even normal regime <strong>of</strong> cookingbecomes extremely cumbersome <strong>and</strong> difficult. The R & D efforts at DFRL are aimed at designing <strong>and</strong>engineering light weight convenient, pack rations for Army,Navy,Air force <strong>and</strong> other paramilitaryforces which do not require any elaborate cooking or preparation at the consumer’s end <strong>and</strong> remainshelf-stable under varying climate condition for periods ranging from 6 months to 1 year. Throughenormous <strong>and</strong> substantive contribution, DFRL has developed a wide verity <strong>of</strong> food products <strong>of</strong> Indi<strong>and</strong>ietary matching the mainframe palate tastes <strong>of</strong> the country. Many <strong>of</strong> the DFRL foods, born out <strong>of</strong>innovative state <strong>of</strong> the art technology, lend themselves eminently suitable to industrial scale commercialexploitation by enterprising entrepreneurs <strong>of</strong> different genre. DFRL also has products which are exportworthy <strong>and</strong> amenable to working women. Owing to its singular dedicated contributions in processedfoods, DFRL can be reckoned as the leader in convenience food <strong>and</strong> packed ration developments inthis country. Indigenous ingenuity is the hallmark <strong>of</strong> most <strong>of</strong> the technologies developed at DFRL.Over the decades, the technological advancements have resulted in several innovative technologiesfor various applications. Among the dehydration techniques freeze-drying maintains the quality <strong>of</strong>products which is quite close to that <strong>of</strong> fresh one. During freeze drying the thermal evaporation <strong>of</strong>moisture is through sublimation at low temperatures <strong>and</strong> under high vacuum. Hurdle technology helpsto preserve foods for a period <strong>of</strong> 2-4 months <strong>and</strong> is applicable to fruits, vegetables <strong>and</strong> their productsas well as meat <strong>and</strong> fish products <strong>and</strong> is sparingly used for cereal products preservation. Hurdletechnology is an intelligent combination <strong>of</strong> hurdles such as pH, temperature, water activity, redoxpotential, preservative etc. to ensure the microbial safety as well as sensory <strong>and</strong> nutritional acceptance.Membrane technology is used in the manufacture <strong>of</strong> clarified juices, for initial concentration throughultra filtration, nano-filtration <strong>and</strong> reverse osmosis processes.Thermal treatment is the most widely used technology for preservation <strong>of</strong> foods. Thus retortprocessing <strong>of</strong> foods has been the most promising technique for preservation <strong>of</strong> both vegetarian <strong>and</strong>non-vegetarian foods in the ready-to-eat form. The temperatures in the range <strong>of</strong> 110 – 125ºC are usedfor low acid foods with the main objective <strong>of</strong> inactivating the undesirable micro-organisms to achievecommercial sterilization. High pressure technology is a novel non-thermal processing method <strong>of</strong> foodpreservation where the food is subjected to high hydrostatic pressures in the range <strong>of</strong> 100-600 Mpa atroom temperature. The Armed Forces are the biggest consumer <strong>of</strong> processed foods <strong>and</strong> approximately13 thous<strong>and</strong> tonnes <strong>of</strong> processed food is used annually. They have to subsist mainly on pack rationsduring operational situations. With the advancements in technological methods, Defence FoodResearch Laboratory (DFRL), Mysore, has contributed significantly to develop suitable technologiesfor preserving traditional Indian foods in light weight flexible packages so that pack rations couldbe designed based on such items to meet the nutritional requirements <strong>of</strong> the Defence personnel foroperational situations <strong>and</strong> this has also paved the way for providing variety <strong>of</strong> foods suiting to theirtaste. These efforts led to the development <strong>of</strong> convenience foods based on cereals, pulses, fruits <strong>and</strong>vegetables with a long shelf-life in flexible packs.1

<strong>Chemical</strong> <strong>Analysis</strong> <strong>of</strong> <strong>Value</strong> <strong>Added</strong> <strong>Dairy</strong> <strong>Products</strong> <strong>and</strong> <strong>Their</strong> <strong>Quality</strong> AssuranceFruit <strong>and</strong> vegetable technologiesThe Indian Army operates on hazardous terrain inclusive <strong>of</strong> Siachen Glacier <strong>and</strong> the s<strong>and</strong>y deserts<strong>of</strong> Rajasthan. Similarly, the Indian Navy is a blue water navy <strong>and</strong> the operations go deeper in theoceans to protect the maritime zones used for international shipping. The concept <strong>of</strong> fruit <strong>and</strong> vegetablestorage as such has undergone a change <strong>and</strong> the troops favors precut fruits <strong>and</strong> vegetables in packagedform on operational rations due to the logistic utility <strong>and</strong> convenience. Therefore, minimal processing<strong>of</strong> precut fruits <strong>and</strong> vegetables needs to be emphasized <strong>and</strong> the unit packages can be formulated as perthe ration scales <strong>and</strong> logistic requirements.The futuristic technologies encompass non-thermal processing i.e. high pressure processing <strong>and</strong>pulsed electric field applications. Eco-friendly <strong>and</strong> energy saving technologies are envisaged to occupytheir rightful place in the area <strong>of</strong> fruit <strong>and</strong> vegetable products. Use <strong>of</strong> biodegradable packaging forfresh <strong>and</strong> processed fruits <strong>and</strong> vegetables is a certainty <strong>and</strong> an absolute necessity. It is a common siteto notice heavy accumulation <strong>of</strong> wastage <strong>and</strong> spent packaging material even in partially inhabitatedareas including the high altitude locations. Use <strong>of</strong> biodegradable plastics <strong>and</strong> other materials <strong>of</strong> organicor inorganic origin need to be stressed upon to minimize the pollution hazards in the army locationsas well as the high seas <strong>of</strong> naval operations.Minimal processing <strong>of</strong> fruits <strong>and</strong> vegetablesSupply <strong>of</strong> fruits <strong>and</strong> vegetables in precut <strong>and</strong> packaged form is a challenging task as the precuttingoperations impose severe physiological stress on the commodity. Minimal processing <strong>of</strong> fruits <strong>and</strong>vegetables had been contemplated as a ‘bridge technology’, touching technologies concerned withpost harvest h<strong>and</strong>ling <strong>of</strong> fresh produce on one side <strong>and</strong> conventional process technologies on theother side. It is well accepted notion that minimally processed products can be defined as ‘lightlyprocessed’ products. This does not describe either the living or non living nature <strong>of</strong> the plant tissue. Inother words, it enlarges the horizons <strong>of</strong> minimally processed products giving scope for use <strong>of</strong> minutethermal treatments <strong>and</strong> also application <strong>of</strong> anti-metabolic substances. As such the emphasis is on‘fresh like’ sensory attributes <strong>of</strong> the products <strong>and</strong> any minimal process strategy shall keep the same asthe main objective.Microbiological aspectsMinimally processed fruits <strong>and</strong> vegetables encounter incidence <strong>of</strong> enhanced microbial attacks dueto the elimination <strong>of</strong> natural barriers <strong>of</strong> the plant tissue <strong>and</strong> enhanced accessibility to moisture <strong>and</strong>nutrition on the surface <strong>of</strong> the plant tissue. A number <strong>of</strong> contaminating microorganism includingspoilage organisms <strong>and</strong> pathogens were isolated from precut fruits <strong>and</strong> vegetables. The minimallyprocessed products were successfully subjected to field trials in different Naval comm<strong>and</strong>s <strong>and</strong> thefield trials on zero energy cooling devices were successfully completed in the forward locations <strong>of</strong>desert areas in Rajasthan. Freezing <strong>of</strong> fruits <strong>and</strong> vegetables in whole or precut form is a major problemduring peak winters in high altitude locations such as Ladakh sector. Antifreeze containers with therated capacities <strong>of</strong> 30 <strong>and</strong> 80 kg were field evaluated in Ladakh sector <strong>and</strong> the feed back was highlyencouraging for the induction <strong>of</strong> the same in Armed Forces. As such, the time is ripe for consideration<strong>of</strong> supply <strong>of</strong> precut fruits <strong>and</strong> vegetables to Armed Forces in packaged form <strong>and</strong> the strategies <strong>of</strong> thetransport <strong>and</strong> storage are encompassed to make the supply chain flexible enough to be accommodatedin the existing infrastructure prevailing in the areas <strong>of</strong> army deployment.Ultra high pressure processingThe search for newer methods <strong>of</strong> food processing aims at processing <strong>of</strong> food without resortingto thermal processing. The concept <strong>of</strong> high pressure processing had emerged from the depth <strong>of</strong> theoceans as the sea beds are devoid <strong>of</strong> the usual microorganisms that one can find at sea level. Only afew microorganisms can survive under high pressure conditions <strong>and</strong> the lethality grows manifoldfrom 500 MPa onwards. Ultra high pressure processing is an innovative technological conceptunder the category <strong>of</strong> non thermal processing with minimal or no heat treatment. It is a process2

Novel <strong>and</strong> Emerging Food Technologies for Defence Food Suppliesaimed at controlling growth <strong>of</strong> microbial populations <strong>and</strong> also inactivation <strong>of</strong> quality deterioratingenzymes. High pressure processing involves instantaneous <strong>and</strong> uniform transmission <strong>of</strong> the pressurethroughout the product independent on the product volume. Upon reaching the desired pressurelevel, the pressure can be maintained without further inputs <strong>of</strong> energy. Liquid foods such as fruitjuices can be subjected to high pressure processing holding the required pressure for specific duration<strong>and</strong> decompressing for further aseptic filling as per the st<strong>and</strong>ard procedures <strong>of</strong> aseptic packaging.Apart from these aspects, high pressure processing can also be used for pressure shift freezing, highpressure thawing, texture modifications <strong>and</strong> enhancement <strong>of</strong> nutritive value <strong>of</strong> foods. High pressuresresult in the physical confirmation <strong>of</strong> biological entities such as proteins, resulting in positive changesin the bio-accessibility <strong>of</strong> nutrients.Infrared processing <strong>of</strong> cereals <strong>and</strong> pulsesThe infrared processing is also known as ‘micronising processes <strong>and</strong> is widely used for cookingcereals, oil seeds, pulses <strong>and</strong> also for the processing <strong>of</strong> cocoa. Micronisation is used for the development<strong>of</strong> different types <strong>of</strong> consumer foods, animal feeds inclusive <strong>of</strong> pet foods <strong>and</strong> several brewed products.It is one <strong>of</strong> the most flexible <strong>and</strong> efficient means <strong>of</strong> processing for the development <strong>of</strong> value addedproducts.Infrared radiation has wavelengths between 0.7 <strong>and</strong> 500 µm. Radiation with wavelengthsjust below 0.7 µm consists visible light, whereas radiation with wavelengths just above 500 µm ismicrowave radiation. Infrared radiation with shorter wavelengths transmits more thermal energy t<strong>of</strong>oods in shallow-bed radiators designed for in-depth processing. Such radiators are equipped withglass-encapsulated heaters operating at about 3,000 kW. Microniser consists <strong>of</strong> a long flat moving belt<strong>of</strong> approximately 5 meters in length onto which cereals (wheat, ragi, barley, soy, etc.) are fed at oneend. Above the belt <strong>and</strong> along its length are suspended gas burners which emit infrared energy onthe grains which is carried through the machine by the belt. Infrared energy is absorbed by the moistgrains, causing expansion <strong>of</strong> starch gelatinization. Extent <strong>of</strong> gelatinization depends upon magnitude<strong>of</strong> infrared heat <strong>and</strong> the time the material takes to travel from one end to the other. The exp<strong>and</strong>edgrain upon processing is subjected to flaking, cooling <strong>and</strong> subsequent packaging. Infrared processingimproves starch accessibility for easy digestion <strong>and</strong> the same could be attributed to opening up <strong>of</strong>crystalline starch structurally. Conventional cooking methods also improve the accessibility <strong>of</strong> starchfor digestion but the process may result in nutrient losses besides being a long duration process.Micronization is highly reliable <strong>and</strong> consistent “Short Time High Temperature Process” usinghumidity, temperature <strong>and</strong> mechanical pressure to achieve high levels <strong>of</strong> starch gelatinization <strong>and</strong>elimination <strong>of</strong> anti nutritional factors, without any significant loss in nutrient value. Infrared energymakes the starch s<strong>of</strong>t <strong>and</strong> turgid, causing it to swell, fracture <strong>and</strong> gelatinize. Immediate rolling /flaking or secondary processing enhance the digestibility <strong>and</strong> nutritional value. The nutritive value orprotein quality <strong>of</strong> a food / feed protein depends not only on its content <strong>of</strong> amino-acids but also theirbio-availability. The products as such could be made ready-to-eat or instantized to suit the logisticrequirement <strong>of</strong> defence forces.Retort processing technologyRetort processing <strong>of</strong> foods in rigid, semi rigid <strong>and</strong> flexible packaging systems is the most acceptableform <strong>of</strong> food preservation. It represents a unique combination <strong>of</strong> product, process <strong>and</strong> packagetechnologies with potential, functional, quality <strong>and</strong> economical benefits. The increasing consumerawareness <strong>and</strong> inhibition/dislike to accept other methods <strong>of</strong> food preservation such as use <strong>of</strong> chemicalpreservatives, irradiation etc. has <strong>of</strong>fered a vast scope for retort processed foods.Although retort pouch processing <strong>of</strong> foods is similar to conventional canning, it has certain majoradvantages like (i) Consumes less energy for processing (ii) enhances the quality attributes <strong>and</strong> (iii)reduces the cost <strong>of</strong> transportation <strong>and</strong> storage.Retort processing is generally carried out for low acid foods with a pH more than 4.5 at a temperature<strong>of</strong> 121.1ºC using moist heat. During heat treatment, undesirable spoilage as well as pathogenic3

<strong>Chemical</strong> <strong>Analysis</strong> <strong>of</strong> <strong>Value</strong> <strong>Added</strong> <strong>Dairy</strong> <strong>Products</strong> <strong>and</strong> <strong>Their</strong> <strong>Quality</strong> Assurancemicroorganisms is inactivated / killed <strong>and</strong> thereby the food products become commercially sterile.Thermal destruction <strong>of</strong> microorganisms is measured <strong>and</strong> monitored by time-temperature history,lethality <strong>and</strong> Fo-value.Despite distinct advantages, retort pouch processing <strong>of</strong> foods till recent years did not becomepopular in India as compared to countries like Japan mainly because <strong>of</strong> the high cost <strong>of</strong> processingequipment <strong>and</strong> non-availability <strong>of</strong> indigenous multi layer flexible packaging materials.DFRL, Mysore has been a pioneer in developing the retort processing technology indigenouslyin the country. Over the past two decades, research <strong>and</strong> development work has been carried outin developing multilayer flexible packaging materials as well as designing a simple low cost retort(semi-automatic <strong>and</strong> automatic) amenable to Indian food industry. Due to continuous efforts, DFRLhas so far successfully transferred the retort pouch processing technology to 40 firms for commercialexploitation.Functional foodsFunctional food is a three way concept wherein the (i) agricultural or animal origin serves asraw material, (ii) specific ingredients components <strong>of</strong> the products exerting functionality <strong>and</strong> (iii)physiological effects with respect to human system. Hence the balanced view <strong>of</strong> the three factors,with specific ingredient action, imparts the needful strategic effect. Thus functional food is a recentstrategic application in the food field <strong>and</strong> a driving force for the product development in this century.The functional foods viz. antioxidant rich herbal tea, squash, baked foods, anti-ulcerative fruit spread,low calorie squash for diabetics, fibre rich ash gourd juice, etc. are some <strong>of</strong> the recent developmentsmade in the field.Appetisers are another class <strong>of</strong> functional foods which improve the appetite. The physiologicalmechanism in brief is stimulation <strong>of</strong> trignomial nerves to increase the secretion <strong>of</strong> digestive juices.On the other h<strong>and</strong>, the hormone leptin formed at hypothalmous in the brain for the appetite controlincreases at high altitude stay; thereby satiety setting is signaled <strong>and</strong> results in lack <strong>of</strong> appetite. DFRLhas developed several appetisers for high altitudes which have proved its efficacy for the cause.In conclusion, the food technologies from the ancient to the advanced technologies adopted in thepresent, along with the emerging, promising technologies as well as the present day requirement <strong>of</strong>functional foods have been reviewed in brief. Based on the raw materials i.e., fruits, vegetables, cereals,nuts, medicinal but natural herbs as well as the food requirements <strong>of</strong> the Defence Forces along withthe logistic convenience <strong>of</strong> longer shelf life, ease <strong>of</strong> transportation, DFRL has developed more than100 processed foods with varied technologies adopted. Packed rations with ready-to-eat products,emergency rations with calorie dense products, logistic based foods with functionality, energy densefood bars, functional food bars for low intensity conflicts, convenient processing machine such asautomatic chapathi making machine, automatic coconut processing system, on-line continuousblancher for vegetables, soy paneer making plant, etc. are the important contributions <strong>of</strong> DFRL forDefence Forces, besides the need based techniques <strong>and</strong> quick test kits for meat <strong>and</strong> processed foodswhich are adopted by them.4

<strong>Chemical</strong> <strong>Analysis</strong> <strong>of</strong> <strong>Value</strong> <strong>Added</strong> <strong>Dairy</strong> <strong>Products</strong> <strong>and</strong> <strong>Their</strong> <strong>Quality</strong> AssuranceFunctional foods for infant <strong>and</strong> weaning purposeIndia is among the nations with higher incidence <strong>of</strong> child malnutrition <strong>and</strong> deficiency diseases.According to an estimate more than 50% <strong>of</strong> children are born with low birth weight resulting instunted growth. Lack <strong>of</strong> key nutrients <strong>and</strong> bio-protective components in infancy led to prevalence <strong>of</strong>anaemia <strong>and</strong> infectious disease among children. Mother’s milk is considered as perfect food <strong>of</strong> naturebut in many incidences maternal nursing is not possible <strong>and</strong> new born has to feed with infant formula.Infant formula is the best example <strong>of</strong> designer foods. Normal infant formulas are manufacturedfrom cow’s milk, but this requires substantial alteration to parallel the composition <strong>of</strong> breast milk.These modifications include reduction in protein <strong>and</strong> minerals, an increase in carbohydrates <strong>and</strong> theaddition <strong>of</strong> vitamins <strong>and</strong> trace elements. In recent years, studies have indicated that infants may havean impaired ability <strong>of</strong> synthesizing taurine <strong>and</strong> carnitine, <strong>and</strong> a dietary source is therefore required.Carnitine is necessary for the transportation <strong>of</strong> long chain fatty acids into cell for the β-oxidation <strong>and</strong>energy production. Fatty acid pr<strong>of</strong>ile <strong>of</strong> different fat sources do not meet the complexity <strong>of</strong> maturebreast milk, therefore mixture <strong>of</strong> different fat sources is preferred. Most manufacturers use a mixture<strong>of</strong> vegetable oils (Simmer, 2000). The fat source must also provide the essential fatty acids linoleic(C18:2, ω-6) <strong>and</strong> α-linolenic acid (C18:3, ω-3). A ratio <strong>of</strong> 5:1 <strong>of</strong> ω-6:ω-3, as occurs in breast milk, isbeing suggested. Short chain as well as medium chain fatty acids should also be present in sufficientquantities as they are easy to absorb <strong>and</strong> assimilate. However there is a need for more short-<strong>and</strong>long-term studies before the optimum ratio <strong>and</strong> its effects on growth are evaluated. Linoleic acid <strong>and</strong>α-linolenic acid are the precursors <strong>of</strong> the very-long-chain (C20 - C22), polyunsaturated fatty acids(LCPUFA): Arachidonic <strong>and</strong> docosahexaenoic acid (DHA). LCPUFA are involved in the neural <strong>and</strong>vascular development <strong>of</strong> the fetus <strong>and</strong> neonates <strong>and</strong> are present in human milk.Nucleotides, a component <strong>of</strong> non-protein nitrogen in human milk, may be important for normalimmune function. Supplementation <strong>of</strong> infant formula with nucleotides seems to be beneficial inclinical trials, although further research is needed before routine nucleotide supplementation <strong>of</strong> infantformula can be considered. The success <strong>of</strong> commercially prepared infant formulas has stimulated thedevelopment <strong>of</strong> numerous formulations <strong>and</strong> several hundred varieties <strong>of</strong> proprietary infant formulasare now available throughout the world. In addition, special formulas for use in clinical situations orfor premature infants or for infants with special inborn errors <strong>of</strong> metabolism are available as specialdietary foods.The GI tract <strong>of</strong> infant is dominated by Bifidobacteria which provides health promoting <strong>and</strong>protective properties such as activation <strong>of</strong> immune system, inhibition <strong>of</strong> pathogens by the secretion <strong>of</strong>substances which are directly inhibitory towards several bacteria, lowering <strong>of</strong> pH by the production <strong>of</strong>acids such as acetate <strong>and</strong> lactic acid, leading to an antibacterial environment, production <strong>of</strong> digestiveenzymes such as casein phosphatase <strong>and</strong> lysozyme <strong>and</strong> production <strong>of</strong> vitamins. For these reasons itseems desirable to also increase the numbers <strong>of</strong> Bifidobacteria in the intestinal flora <strong>of</strong> formula-fedinfants. Administration <strong>of</strong> prebiotic oligosaccharides <strong>and</strong> probiotic supplements appear to be the mosteffective way to increase the number <strong>of</strong> the Bifidobacteria in the intestine. Human milk oligosaccharidesare mainly responsible for Bifidogenic effects <strong>of</strong> breast milk. Several commercial formulations havebeen developed with the view <strong>of</strong> providing a predominance <strong>of</strong> Bifidobacteria in the intestinal floraformula-fed infants. However the inclusion <strong>of</strong> such unconventional ingredients in formulation <strong>of</strong>infant formula needs long-term investigations before being approved.Inadequate nutrition during first 2-3 years <strong>of</strong>ten leads to problems associated with malnutrition inseveral developing nations in the world. Complementary nutrition is must for the normal <strong>and</strong> healthygrowth <strong>of</strong> a child after the age <strong>of</strong> 6 months, owing to increased requirement <strong>of</strong> nutrition in additionto those provided by breast milk. Moreover the food preparations consumed as weaning foods donot contain adequate nutrients desired for children. Traditional infant-feeding practiced, in countrieslike India, is usually cereal based. For the preparation <strong>of</strong> such foods grains are <strong>of</strong>ten germinated,6

An Overview <strong>of</strong> Designer Functional <strong>and</strong> Health Foodsfermented, processed <strong>and</strong> cooked in various ways to improve digestibility, <strong>and</strong> mixed with oilseeds oranimal products to enhance their nutritional pr<strong>of</strong>ile, however most <strong>of</strong> these complementary foods arereported to be less energy dense <strong>and</strong> less safer for children because <strong>of</strong> the higher proportion <strong>of</strong> antinutrients.Cereals in combination with milk solids are generally used for the preparation <strong>of</strong> weaningfoods. Milk-Cereal-millet based complementary foods appear to be unique in the sense that they c<strong>and</strong>eliver multitude <strong>of</strong> nutrients to children <strong>and</strong> complement each other as well. The correct form <strong>of</strong>incorporation, effective concentration <strong>and</strong> required technological inputs determine the effectiveness<strong>of</strong> the resulted complementary food. Such products could be an attractive option for mass childrenfeeding programmes.Specialized foods with plant bioactiveNutritional significance <strong>of</strong> plant molecules is well documented <strong>and</strong> increasing cases <strong>of</strong> cancers,coronary heart diseases, diabetes <strong>and</strong> many other chronic diseases, have been attributed to underconsumption <strong>of</strong> fruits <strong>and</strong> vegetables in our diet. But beyond these known nutrients i.e. vitamins,fibers, plants have clearly more to <strong>of</strong>fer <strong>and</strong> scientists are scurrying to discover exactly which plantcomponents might fend <strong>of</strong>f specific diseases. An ever-exp<strong>and</strong>ing array <strong>of</strong> previously unknown plantmolecules with hard to pronounce names are being uncovered. But there exact metabolic role <strong>and</strong> howthese can be utilized in designer food, need to be clarified.The number <strong>of</strong> identified physiologically has increased dramatically in the last decades <strong>and</strong>overwhelming evidence from epidemiological, in vivo, in vitro <strong>and</strong> clinical trial indicate that plant richdiet can reduce the risk <strong>of</strong> certain chronic diseases (Hasler, 2000) Health pr<strong>of</strong>essionals are graduallyrecognizing the role <strong>of</strong> phytochemicals in health improvement. The major mechanism associated withtherapeutic aspects <strong>of</strong> plant bioactive is their ability to act as antioxidants.There are certain other compounds present in plant foods, with significant health promoting effectinclude plant fatty acids, tocotrienols, phenolic derivatives <strong>and</strong> dietary fibers etc. Docosahexaenoicacid (DHA), which is one <strong>of</strong> the most important structural component <strong>of</strong> brain <strong>and</strong> retina, <strong>and</strong> de-novosynthesis <strong>of</strong> this compound, is very rare. The decline in DHA intake could have serious implications forpublic health, since low plasma, DHA concentrations have been correlated with increased incidence <strong>of</strong>number <strong>of</strong> important chronic diseases such as depression, attention deficit disorders <strong>and</strong> Alzheimer’sdementia. Crypthecodinium cohmii strain <strong>of</strong> marine algae is used for the commercial production <strong>of</strong> DHArich oil. Spirulina, termed as wonder alga is one <strong>of</strong> riches source <strong>of</strong> omeg-3-fatty acids, quality protein<strong>and</strong> many other therapeutic molecules.Plant polyphenols are secondary metabolites widely distributed in higher plants. Polyphenolshistorically have been considered as anti-nutrients by nutritionists, because some, eg. tannins havesuch adverse effects as decreasing the activities <strong>of</strong> digestive enzymes, energy, protein <strong>and</strong> amino acidavailabilities, mineral uptake <strong>and</strong> having other toxic effects. Recognition <strong>of</strong> the antioxidant activities<strong>of</strong> many polyphenols has realigned thinking toward the health benefits provided by many <strong>of</strong> thesecompounds. Phytoestrogens are a broad group <strong>of</strong> plant-derived compounds that are structuralmimics <strong>of</strong> endogenous 17 beta-estradiol. Two major phytoestrogens, which are <strong>of</strong> great importancefrom nutritional <strong>and</strong> health perspectives, include lignans (Flaxseed) <strong>and</strong> is<strong>of</strong>lavones (soy bean).These compounds either compete with or antagonize estrdiol action. Exact biochemical mechanisminvolving CYP3A monoxygenase activity in presence <strong>of</strong> phase I enzyme inducers such as dixamethane.Phytosterols are another important terpene subclass. Two sterol molecules that are synthesized byplants are β - sitosterol <strong>and</strong> its glycoside. In animals, these two molecules exhibit anti-inflammatory,anti-neoplastic, anti-pyretic <strong>and</strong> immune-modulating activity. In the body, phytosterols can competewith cholesterol in the intestine for uptake, <strong>and</strong> aid in the elimination <strong>of</strong> cholesterol from the body.Saturated phytosterols appear to be more effective than unsaturated ones in decreasing cholesterolconcentrations in the body. Certain designer foods like phytosterol containing yoghurt, β-glucan richdairy drink, DHA containing infant foods etc. have already reach to the stage <strong>of</strong> commercialization.7

<strong>Chemical</strong> <strong>Analysis</strong> <strong>of</strong> <strong>Value</strong> <strong>Added</strong> <strong>Dairy</strong> <strong>Products</strong> <strong>and</strong> <strong>Their</strong> <strong>Quality</strong> AssuranceMilk proteins <strong>and</strong> peptides based nutraceuticalsDietary proteins possess nutritional, functional <strong>and</strong> biological properties, <strong>and</strong> the technologicalprocesses used in food manufacture <strong>and</strong> processing <strong>of</strong>ten affect these properties. The role <strong>of</strong> proteinsas physiologically active components in the diet has been increasingly acknowledged in recent years.Such proteins or their precursors may occur naturally in raw food materials, exerting their physiologicalaction directly or upon enzymatic hydrolysis in vitro or in vivo. Several dietary proteins, can act as asource <strong>of</strong> biologically active peptides. These peptides inactive within remain the parent protein, <strong>and</strong>released during gastrointestinal digestion or food processing. Once liberated, the bioactive peptidesmay provide different functions in vitro or in vivo.Bioactive peptides have to be released from the parent protein by enzymatic hydrolysis. Thiscan be achieved by the use <strong>of</strong> isolated enzymes, as well by microbial fermentation. Biologicallyactive peptides are <strong>of</strong> particular interest for pharma industry because they have been shown to playdifferent physiological roles, including opioid like activity, antimicrobial, immunomodulatory <strong>and</strong>antihypertensive. Such peptides can be released during hydrolysis by digestive or microbial enzymes.Microbial enzymes from lactic acid bacteria have demonstrated to be able to liberate theses peptidesfrom milk proteins, in various fermented milk products.Upon oral administration bioactive peptides may affect the major body systems- namely thecardiovascular, digestive, immune <strong>and</strong> nervous systems. For this reason, the potential <strong>of</strong> certainpeptides sequences to reduce the risk <strong>of</strong> chronic diseases or boost natural immune protection hasaroused a lot <strong>of</strong> scientific interest over the past few years. These beneficial health effects may beattributed to known peptide sequences exhibiting, e.g., antimicrobial, antioxidative, antithrombotic,antihypertensive <strong>and</strong> immunomodulatory activities. Milk proteins are considered the most importantsource <strong>of</strong> bioactive peptides <strong>and</strong> an increasing number <strong>of</strong> bioactive peptides have been identified inmilk protein hydrolysates <strong>and</strong> fermented dairy products.Over the last few years a number <strong>of</strong> investigations have been carried out across the world toelucidate the bioactivity <strong>of</strong> milk proteins <strong>and</strong> derivatives. These components may be either serve asfunctional ingredients in development <strong>of</strong> functional foods or can be utilized by pharma industry asnutraceuticals. Most <strong>of</strong> the claimed physiological properties <strong>of</strong> milk proteins <strong>and</strong> derivatives havebeen carried out in in-vitro or animal models, these hypothesized properties remains to be proven inhumans. Whey proteins are becoming an important constituent in the recipe <strong>of</strong> wide range <strong>of</strong> functional<strong>and</strong> health foods because <strong>of</strong> the unique amino acid composition <strong>and</strong> bioactivity. Whey proteins basedcommercially available food products include sports supplements, low fat dairy desserts, medicalfoods, infant formulations <strong>and</strong> geriatric foods. Antihypertensive bioactive peptides may be utilized indevelopment <strong>of</strong> mood drinks <strong>and</strong> also foods for cardiac patients.Other prospective designer foodsBeverages are another range <strong>of</strong> products that <strong>of</strong>fer tremendous market potential for Indian foodindustry because <strong>of</strong> being nutritionally-rich. Similarly, minor cereals <strong>and</strong> millets based milk beveragesseem to be lucrative products for school feeding programmes. Liquid milk fortification with vitamins A<strong>and</strong>/D is m<strong>and</strong>atory in several countries. However, the milk fortification usually impaired its sensory<strong>and</strong> processing quality characteristics. Moreover, bio-availability <strong>of</strong> fortified nutrients is another majorconcern. Investigations carried out at NDRI suggest possibilities <strong>of</strong> fortification <strong>of</strong> liquid milk withcalcium <strong>and</strong> iron. Beverages <strong>and</strong> soups based on whey continue to receive a considerable amount<strong>of</strong> attention nowadays. These indicate the growing awareness among consumers <strong>and</strong> manufacturersalike for the enormous potential these <strong>of</strong>fered for diversifying product pr<strong>of</strong>ile. Other designer foodsinclude low calories/low fat variants, low sodium foods <strong>and</strong> fun foods etc.ConclusionConsumer interest in the relationship between diet <strong>and</strong> health has increased the dem<strong>and</strong> forinformation on functional foods. Rapid advances in science <strong>and</strong> technology, increasing healthcare8

An Overview <strong>of</strong> Designer Functional <strong>and</strong> Health Foodscosts, changes in food laws affecting label <strong>and</strong> product claims, an aging population, <strong>and</strong> rising interestin attaining wellness through diet are among the factors fueling interest in functional foods. Crediblescientific research indicates many potential health benefits from milk components.ReferencesFinley, J.W. 2005. Proposed criteria for assessing the efficacy <strong>of</strong> cancer reduction by plant foods enriched in carotenoids,glucosinolates, polyphenols <strong>and</strong> selenocompounds. Annals <strong>of</strong> Botany, 95:1075-1096 pp.Hasler, C.M. 1998. Functional Foods: <strong>Their</strong> role in disease prevention <strong>and</strong> health promotion. Food Technology 52(11),63-70 ppHasler, C.M. 2000. The changing face <strong>of</strong> functional foods. Journal <strong>of</strong> American College <strong>of</strong> Nutrition 19 (5), 499S-506S pp.Hirayama, M. 2002. Novel physiological functions <strong>of</strong> oligosaccharides. Pure Appl. Chem. 74 (7) 1271-1279 ppShah, N. P. 2000. Probiotic Bacteria: Slective Enumeration <strong>and</strong> survival in dairy foods. J. <strong>Dairy</strong> Science, 88:894-907Simmer, K. 2000 a. Long-chain polyunsaturated fatty acid supplementation in preterm infants. Cochrane Database Syst.Rev., -HD-(2): CD 000375 2000.Wollowski, I. 2001. Protective role <strong>of</strong> probiotics <strong>and</strong> prebiotics in colon cancer. Am. J. Clin. Nutrition: 73 (Suppl):451S-5S9

<strong>Chemical</strong> <strong>Analysis</strong> <strong>of</strong> <strong>Value</strong> <strong>Added</strong> <strong>Dairy</strong> <strong>Products</strong> <strong>and</strong> <strong>Their</strong> <strong>Quality</strong> AssuranceIntroduction:Prospects <strong>of</strong> <strong>Value</strong> Addition ThroughFunctional IngredientsG. R. Patil<strong>Dairy</strong> Technology Division, NDRI, KarnalIn recent years, there has been a vast <strong>and</strong> rapidly growing body <strong>of</strong> scientific data showing thatdiet plays an important part in diseases. Diet is thought to contribute to six <strong>of</strong> the 10 leading causes <strong>of</strong>death. Nutrients <strong>and</strong> nonnutritive food components have been associated with the prevention <strong>and</strong>/or treatment <strong>of</strong> chronic diseases such as cancer, coronary heart disease, diabetes, hypertension, <strong>and</strong>osteoporosis. Up to 70% <strong>of</strong> certain cancers may be attributed to diet. As the data supporting the role<strong>of</strong> diet in health promotion <strong>and</strong> disease prevention continue to mount, it is likely that the quantity <strong>of</strong>enhanced foods will exp<strong>and</strong> substantially. There is an increasing dem<strong>and</strong> by consumers for quality<strong>of</strong> life, which is fueling the functional foods revolution. Functional foods are viewed as one optionavailable for seeking cost-effective health care <strong>and</strong> improved health status. Moreover, the large babyboomersegment <strong>of</strong> the population is aging <strong>and</strong> considerable health care budget in most country isfocused on treatment rather than prevention. Thus, the use <strong>of</strong> nutraceuticals in daily diets can be seenas means to reduce escalating health care costs that will contribute not only to a longer lifespan, butalso more importantly, to a longer health span. Development <strong>of</strong> functional food products will continueto grow throughout the 21 st century as consumer dem<strong>and</strong> for healthful products grows.The exploding area <strong>of</strong> functional foods <strong>and</strong> probiotics shows considerable promise to exp<strong>and</strong>the industry into new arenas. Both convenience <strong>and</strong> better for you attitudes are selling. Consumersclearly believe in the concept <strong>of</strong> functional nutrition, or specific association between foods/nutrients<strong>and</strong> health functions. They are interested in foods that boost the immure system, reduce the risk <strong>of</strong>disease <strong>and</strong> enhance health, which consumers self-prescribe for themselves <strong>and</strong> their families. Hence,there are clear opportunities to <strong>of</strong>fer consumers dietary alternatives to medical solutions. Theseopportunities, however, will be highly consumer driven <strong>and</strong> success will ultimately be dependentupon defining your segment <strong>and</strong> knowing your target group.The markets <strong>of</strong> traditional dairy products are increasingly getting overcrowded <strong>and</strong> our futuresuccess will depend on our ability to provide innovative products, which consumers want <strong>and</strong> need.Whatever the innovation - products, processing method or packaging - it should meet the real consumerneed. We know today’s families want “grab-<strong>and</strong>-go” convenience. They are also concerned aboutnutrition <strong>and</strong> health. Different ages <strong>and</strong> demographics want different things. Therefore, investment atthis level is essential if we are to respond rapidly to customers who are increasingly dem<strong>and</strong>ing new <strong>and</strong>different taste experiences from products that are also competitively priced. Thanks to advancementsin technology, researchers have shown that specific components <strong>of</strong> milk, as well as ingredients canbe readily added to dairy products, which contribute to health <strong>and</strong> wellness, <strong>and</strong> assist consumerswith feeling balanced <strong>and</strong> satisfied. There is a golden opportunity for dairy marketers to formulateinnovative products to meet consumers’ needs <strong>and</strong> to effectively market the product’s value. Newvariants <strong>of</strong> sweets can be developed. <strong>Dairy</strong> products containing health-promoting ingredients may bedeveloped <strong>and</strong> promoted. Host <strong>of</strong> ingredients with health benefits are available for value addition <strong>of</strong>dairy products. Some <strong>of</strong> these issues are discussed hereunder.Functional ingredients for value additionFunctional nutrition is a broad topic, <strong>and</strong> covers many ingredient categories. The functionalcomponents used in formulation <strong>of</strong> these formulated foods are given in Table 1.10

Prospects <strong>of</strong> <strong>Value</strong> Addition Through Functional IngredientsTable 1: Examples <strong>of</strong> Functional Ingredients*Class/ Ingredients Source* Potential BenefitCarotenoidsBeta-carotene carrots, various fruits neutralizes free radicals which maydamage cells; bolsters cellularantioxidant defensesLutein, Zeaxanthinkale, collards, spinach, corn, eggs,citrusmay contribute to maintenance <strong>of</strong>healthy visionLycopenetomatoes <strong>and</strong> processed tomatoproductsmay contribute to maintenance <strong>of</strong>prostate healthDietary (functional <strong>and</strong> total) FiberInsoluble fi ber wheat bran may contribute to maintenance <strong>of</strong> ahealthy digestive tractBeta glucan oat bran, rolled oats, oat fl our may reduce risk <strong>of</strong> coronary heartdisease (CHD)Soluble fi ber psyllium seed husk may reduce risk <strong>of</strong> CHDWhole grains cereal grains may reduce risk <strong>of</strong> CHD <strong>and</strong> cancer;may contribute to maintenance <strong>of</strong>healthy blood glucose levelsFatty AcidsMonounsaturated fatty acids(MUFAs)tree nutsmay reduce risk <strong>of</strong> CHDPolyunsaturated fatty acids (PUFAs)- Omega-3 fatty acids—ALAPUFAs - Omega-3 fatty acids—DHA/EPAPUFAs - Conjugated linoleic acid(CLA)walnuts, fl axsalmon, tuna, marine <strong>and</strong> other fi shoilsbeef <strong>and</strong> lamb; some cheesemay contribute to maintenance <strong>of</strong>mental <strong>and</strong> visual functionmay reduce risk <strong>of</strong> CHD; maycontribute to maintenance <strong>of</strong> mental<strong>and</strong> visual functionmay contribute to maintenance <strong>of</strong>desirable body composition <strong>and</strong>healthy immune functionFlavonoidsAnthocyanidins berries, cherries, red grapes bolster cellular antioxidant defenses;may contribute to maintenance <strong>of</strong>brain functionFlavanols—Catechins, Epicatechins,Procyanidinstea, cocoa, chocolate, apples,grapesmay contribute to maintenance <strong>of</strong>heart healthFlavanones citrus foods neutralize free radicals which maydamage cells; bolster cellularantioxidant defensesFlavonols onions, apples, tea, broccoli neutralize free radicals which maydamage cells; bolster cellularantioxidant defensesProanthocyanidinsIsothiocyanatesSulforaphanePhenolsCaffeic acid, Ferulic acidcranberries, cocoa, apples,strawberries, grapes, wine, peanuts,cinnamoncaulifl ower, broccoli, broccoli sprouts,cabbage, kale, horseradishapples, pears, citrus fruits, somevegetablesmay contribute to maintenance <strong>of</strong>urinary tract health <strong>and</strong> heart healthmay enhance detoxifi cation <strong>of</strong>undesirable compounds <strong>and</strong> bolstercellular antioxidant defensesmay bolster cellular antioxidantdefenses; may contribute tomaintenance <strong>of</strong> healthy vision <strong>and</strong>heart health11

<strong>Chemical</strong> <strong>Analysis</strong> <strong>of</strong> <strong>Value</strong> <strong>Added</strong> <strong>Dairy</strong> <strong>Products</strong> <strong>and</strong> <strong>Their</strong> <strong>Quality</strong> AssuranceClass/ Ingredients Source* Potential BenefitPlant Stanols/SterolsFree Stanols/Sterolscorn, soy, wheat, wood oils, fortifi ed may reduce risk <strong>of</strong> CHDfoods <strong>and</strong> beveragesStanol/Sterol estersfortifi ed table spreads, stanol ester may reduce risk <strong>of</strong> CHDdietary supplementsPolyolsSugar alcohols—xylitol, sorbitol,mannitol, lactitolInulin, Fructo-oligosaccharides(FOS), PolydextroseLactobacilli, Bifi dobacteria12some chewing gums <strong>and</strong> other foodapplicationsPrebiotic/Probioticswhole grains, onions, some fruits,garlic, honey, leeks, fortifi ed foods<strong>and</strong> beveragesyogurt, other dairy <strong>and</strong> non-dairyapplicationsmay reduce risk <strong>of</strong> dental cariesmay improve gastrointestinal health;may improve calcium absorptionmay improve gastrointestinal health<strong>and</strong> systemic immunityPhytoestrogensIs<strong>of</strong>l avones—Daidzein, Genistein soybeans <strong>and</strong> soy-based foods may contribute to maintenance<strong>of</strong> bone health, healthy brain <strong>and</strong>immune function; for women,maintenance <strong>of</strong> menopausal healthLignans fl ax, rye, some vegetables may contribute to maintenance <strong>of</strong>heart health <strong>and</strong> healthy immunefunctionSoy ProteinSoy Protein soybeans <strong>and</strong> soy-based foods may reduce risk <strong>of</strong> CHDSulfi des/ThiolsDiallyl sulfi de, Allyl methyl trisulfi de garlic, onions, leeks, scallions may enhance detoxifi cation <strong>of</strong>undesirable compounds; maycontribute to maintenance <strong>of</strong> hearthealth <strong>and</strong> healthy immune functionDithiolthiones cruciferous vegetables contribute to maintenance <strong>of</strong> healthyimmune functionSource: IIFC (2004)Examples are not an all-inclusive list.Several functional dairy products can be developed using either single or combination <strong>of</strong>ingredients given in the table targeting specific health benefits. Besides these functional ingredients,which are mostly obtained from plant source, there are other ingredients such as fat replacers, artificialsweeteners, micronutrients like vitamins <strong>and</strong> minerals, which can be used for value addition.3.0 What are the possibilities?Innovative milk beverages:Recently, a whole new generation <strong>of</strong> beverages containing milk <strong>and</strong> dairy ingredient are emerging.Thanks to new technologies, including processes <strong>and</strong> ingredients, such dairy based beverages not only<strong>of</strong>fer a wider range <strong>of</strong> flavour, texture <strong>and</strong> other sensory properties than are current present but alsoprovides new marketing opportunities for these products in the healthy/ neutraceutical/ bioactivefoods category foods today’s consumer’s want. Some <strong>of</strong> the ingredients highlighted above, along withother ingredients that are currently used or can be used for development <strong>of</strong> such beverages. <strong>Dairy</strong>manufacturers can develop a signature formula to appeal to specific market segments.Select European countries use whey as a base for nutritional, fruity dairy-based beverages. A refreshingbeverage made from fermented milk <strong>and</strong> whey <strong>and</strong> containing fruit juice, or a probiotic beverage fromwhey <strong>and</strong> fruit juice that is fortified with vitamins <strong>and</strong> calcium are being marketed in these countries.NDRI has also recently developed formulations from whey such as whey-jaljeera beverage, whey-baelbeverage, <strong>and</strong> whey –mango beverage, which are available for commercial exploitation.

Prospects <strong>of</strong> <strong>Value</strong> Addition Through Functional IngredientsProbiotic dairy products:“Probiotic, food products in generals <strong>and</strong> “probiotic “ organism in particular are in the center <strong>of</strong>current R & D activities all over the world. “Functional foods” segment that is registering a steady<strong>and</strong> consistent growth at present, among processed food products, gathered the momentum primarilyfrom the scientific investigations based on “probiotic” food products. A probiotic is a mono-or mixedculture <strong>of</strong> live microorganisms which benefits man or animals by improving the properties <strong>of</strong> theindigenous micr<strong>of</strong>lora. Viable counts delivered to the gastrointestinal tract are key to the functionality<strong>of</strong> probiotics. The consumption <strong>of</strong> probiotic culture positively affect the composition <strong>of</strong> this micr<strong>of</strong>loraor extends a range <strong>of</strong> host benefits including.1. Pathogen interference, exclusion <strong>and</strong> antagonism.2. Immunostimulation <strong>and</strong> immunomodulation.3. Anticarcinogenic or antimutagenic activities.4. Alleviation <strong>of</strong> symptoms <strong>of</strong> lactose intolerance.5. Reductiion in serum cholesterols.6. Reduction in blood pressures.7. Decreased incidence & duration <strong>of</strong> diarrhoea.8. Prevention <strong>of</strong> vaginitis.9. Maintenance <strong>of</strong> mucosal integrity.Industrial interest in developing probiotics <strong>and</strong> probiotic functional foods is thriving, drivenlargely by the market potential for foods that target general health or well being. NDRI has madesome progress in this area by developing probiotic dahi, lassi <strong>and</strong> probiotic cheese. There is possibility<strong>of</strong> developing other milk based fermented traditional dairy products such as probiotic shrik<strong>and</strong> <strong>and</strong>Rabadi – a milk-cereal based fermented product.Fat-replacement in dairy products:High fat consumption has been linked to several chronic diseases including cardiovascular diseases,obesity <strong>and</strong> certain forms <strong>of</strong> cancer. Nutrition experts recommend a total fat intake <strong>of</strong> less than 30 percent <strong>of</strong> total daily calories. These dietary recommendations are one reason for the increasing dem<strong>and</strong>for lower fat food products <strong>of</strong> the world market has been flooded with the food products carrying thelabels “low fat”, ‘no fat’ or ‘reduced fat’. Fat mimics or fat substitutes are normally used to producelow-fat foods, fat mimics are substances that help replace the mouthfeel <strong>of</strong> fat but can not substitutefor fat on a gram for gram basis <strong>and</strong> can not be used for applications involving frying. Substanceswhose physical or thermal properties resemble fat are termed as fat substitutes <strong>and</strong> can replace fat ona gram-for gram basis <strong>and</strong> can also be used for frying applications.Categories <strong>of</strong> fat replacersFat mimicsFat replacersProtein based Carbohydrate based -Emulsifiers-Medium chain triacylglycerols.- whey protein conc. - Starches -Structural lipids.- Microparticulated protein - Maltodextrins -Acaloric synthetic compounds.- Polydextrose * fatty alcohol esters <strong>of</strong> alkylmalonic or malonic acid.* esterified propoxylated glycerols* trialkoxy tricarballylate* poly carboxylic acid.* Sucrose polyestersLow-fat cheese, processed cheese, cultured products, frozen desserts, butters <strong>and</strong> spreads havebeen successfully developed using commercially available fat mimics/replacers. Using similartechnique several low fat varieties <strong>of</strong> traditional dairy products can be developed. An attempt hasbeen made to develop low fat burfi at this institute.13