assembly and erection of pamunkey river bridge bascules

assembly and erection of pamunkey river bridge bascules

assembly and erection of pamunkey river bridge bascules

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

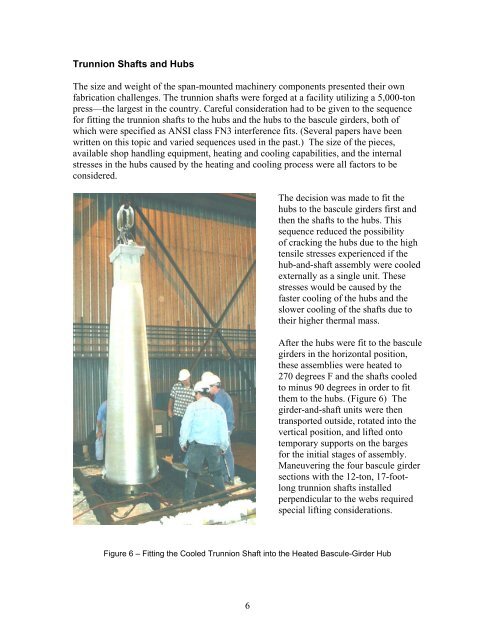

Trunnion Shafts <strong>and</strong> HubsThe size <strong>and</strong> weight <strong>of</strong> the span-mounted machinery components presented their ownfabrication challenges. The trunnion shafts were forged at a facility utilizing a 5,000-tonpress—the largest in the country. Careful consideration had to be given to the sequencefor fitting the trunnion shafts to the hubs <strong>and</strong> the hubs to the bascule girders, both <strong>of</strong>which were specified as ANSI class FN3 interference fits. (Several papers have beenwritten on this topic <strong>and</strong> varied sequences used in the past.) The size <strong>of</strong> the pieces,available shop h<strong>and</strong>ling equipment, heating <strong>and</strong> cooling capabilities, <strong>and</strong> the internalstresses in the hubs caused by the heating <strong>and</strong> cooling process were all factors to beconsidered.The decision was made to fit thehubs to the bascule girders first <strong>and</strong>then the shafts to the hubs. Thissequence reduced the possibility<strong>of</strong> cracking the hubs due to the hightensile stresses experienced if thehub-<strong>and</strong>-shaft <strong>assembly</strong> were cooledexternally as a single unit. Thesestresses would be caused by thefaster cooling <strong>of</strong> the hubs <strong>and</strong> theslower cooling <strong>of</strong> the shafts due totheir higher thermal mass.After the hubs were fit to the basculegirders in the horizontal position,these assemblies were heated to270 degrees F <strong>and</strong> the shafts cooledto minus 90 degrees in order to fitthem to the hubs. (Figure 6) Thegirder-<strong>and</strong>-shaft units were thentransported outside, rotated into thevertical position, <strong>and</strong> lifted ontotemporary supports on the bargesfor the initial stages <strong>of</strong> <strong>assembly</strong>.Maneuvering the four bascule girdersections with the 12-ton, 17-footlongtrunnion shafts installedperpendicular to the webs requiredspecial lifting considerations.Figure 6 – Fitting the Cooled Trunnion Shaft into the Heated Bascule-Girder Hub6