belt drive models - Whirlpool

belt drive models - Whirlpool

belt drive models - Whirlpool

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

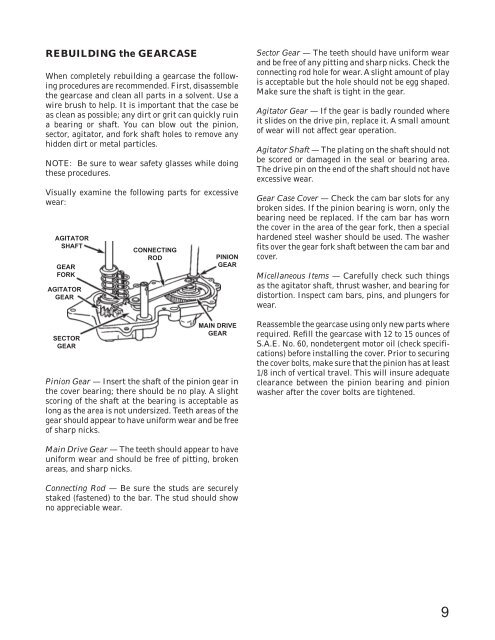

REBUILDING the GEARCASEWhen completely rebuilding a gearcase the followingprocedures are recommended. First, disassemblethe gearcase and clean all parts in a solvent. Use awire brush to help. It is important that the case beas clean as possible; any dirt or grit can quickly ruina bearing or shaft. You can blow out the pinion,sector, agitator, and fork shaft holes to remove anyhidden dirt or metal particles.NOTE: Be sure to wear safety glasses while doingthese procedures.Visually examine the following parts for excessivewear:AGITATORSHAFTGEARFORKAGITATORGEARSECTORGEARCONNECTINGRODPINIONGEARMAIN DRIVEGEARPinion Gear — Insert the shaft of the pinion gear inthe cover bearing; there should be no play. A slightscoring of the shaft at the bearing is acceptable aslong as the area is not undersized. Teeth areas of thegear should appear to have uniform wear and be freeof sharp nicks.Sector Gear — The teeth should have uniform wearand be free of any pitting and sharp nicks. Check theconnecting rod hole for wear. A slight amount of playis acceptable but the hole should not be egg shaped.Make sure the shaft is tight in the gear.Agitator Gear — If the gear is badly rounded whereit slides on the <strong>drive</strong> pin, replace it. A small amountof wear will not affect gear operation.Agitator Shaft — The plating on the shaft should notbe scored or damaged in the seal or bearing area.The <strong>drive</strong> pin on the end of the shaft should not haveexcessive wear.Gear Case Cover — Check the cam bar slots for anybroken sides. If the pinion bearing is worn, only thebearing need be replaced. If the cam bar has wornthe cover in the area of the gear fork, then a specialhardened steel washer should be used. The washerfits over the gear fork shaft between the cam bar andcover.Micellaneous Items — Carefully check such thingsas the agitator shaft, thrust washer, and bearing fordistortion. Inspect cam bars, pins, and plungers forwear.Reassemble the gearcase using only new parts whererequired. Refill the gearcase with 12 to 15 ounces ofS.A.E. No. 60, nondetergent motor oil (check specifications)before installing the cover. Prior to securingthe cover bolts, make sure that the pinion has at least1/8 inch of vertical travel. This will insure adequateclearance between the pinion bearing and pinionwasher after the cover bolts are tightened.Main Drive Gear — The teeth should appear to haveuniform wear and should be free of pitting, brokenareas, and sharp nicks.Connecting Rod — Be sure the studs are securelystaked (fastened) to the bar. The stud should showno appreciable wear.9