Applied aeronautics; the airplane - Beeldbibliotheek

Applied aeronautics; the airplane - Beeldbibliotheek

Applied aeronautics; the airplane - Beeldbibliotheek

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

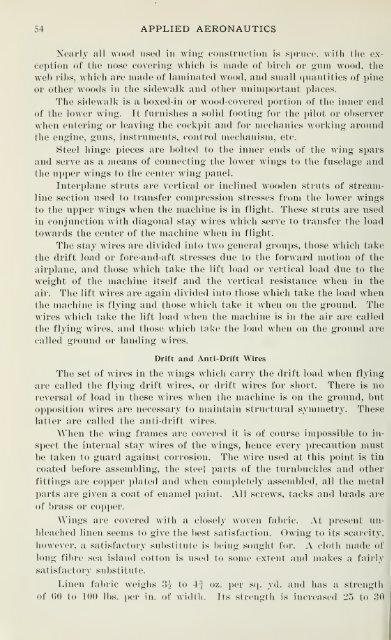

54 APPLIED AERONAUTICSNearly all wood used in wing construction is spruce, with <strong>the</strong> exceptionof <strong>the</strong> nose covering which is made of birch or gum wood, <strong>the</strong>web ribs, which are made of laminated wood, and small quantities of pineor o<strong>the</strong>r woods in <strong>the</strong> sidewalk and o<strong>the</strong>r unimportant places.The sidewalk is a boxed-in or wood-covered portion of <strong>the</strong> inner endof <strong>the</strong> lower wing. It furnishes a solid footing for <strong>the</strong> pilot or observerwhen entering or leaving <strong>the</strong> cockpit and for mechanics working around<strong>the</strong> engine, guns, instruments, control mechanism, etc.Steel hinge pieces are bolted to <strong>the</strong> inner ends of <strong>the</strong> wing sparsand serve as a means of connecting <strong>the</strong> lower wings to <strong>the</strong> fuselage and<strong>the</strong> upper wings to <strong>the</strong> center wing panel.Interplane struts are vertical or inclined wooden struts of streamlinesection used to transfer compression stresses from <strong>the</strong> lower wingsto <strong>the</strong> upper wings when <strong>the</strong> machine is in flight. These struts are usedin conjunction with diagonal stay wires which serve to transfer <strong>the</strong> loadtowards <strong>the</strong> center of <strong>the</strong> machine when in flight.The stay wires are divided into two general groups, those which take<strong>the</strong> drift load or fore-and-aft stresses due to <strong>the</strong> forward motion of <strong>the</strong><strong>airplane</strong>, and those which take <strong>the</strong> lift load or vertical load due to <strong>the</strong>weight of <strong>the</strong> machine itself and <strong>the</strong> vertical resistance when in <strong>the</strong>air. The lift wires are again divided into those which take <strong>the</strong> load when<strong>the</strong> machine is flying and those which take it when on <strong>the</strong> ground. Thewires which take <strong>the</strong> lift load when <strong>the</strong> nuichine is in <strong>the</strong> air are called<strong>the</strong> flying wires, and those which take <strong>the</strong> load when on <strong>the</strong> ground arecalled ground or landing wires.Drift and Anti-Drift WiresThe set of wires in <strong>the</strong> wings which carry <strong>the</strong> drift load when flyingarecalled <strong>the</strong> flying drift wires, or drift wires for short. There is noreversal of load in <strong>the</strong>se wires when <strong>the</strong> machine is on <strong>the</strong> ground, butopposition wires are necessary to maintain structural symmetry. Theselatter are called <strong>the</strong> anti-drift wires.When <strong>the</strong> wing frames are covered it is of course impossible to inspect<strong>the</strong> internal stay wires of <strong>the</strong> wings, hence every precaution mustbe taken to guard against corrosion. The wire used at this point is tincoated before assembling, <strong>the</strong> steel parts of <strong>the</strong> turnbuckles and o<strong>the</strong>rfittings are copper plated and when completely assembled, all <strong>the</strong> metalparts are given a coat of enamel paint.All screws, tacks and brads areof brass or copper.Wings are covered with a closely woven fabric. At present unbleachedlinen seems to give <strong>the</strong> best satisfaction. Owing to its scarcity,ho^^ever, a satisfactory substitute is being sought for. A cloth made oflong fibre sea island cotton is used to some extent and makes a fairlysatisfactory substitute.Linen fabric weighs 3^ to 4f oz. per sq. yd. and has a strengthof GO to 100 lbs. per in. of width. Its strength is increased 25 to 30