Applied aeronautics; the airplane - Beeldbibliotheek

Applied aeronautics; the airplane - Beeldbibliotheek

Applied aeronautics; the airplane - Beeldbibliotheek

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

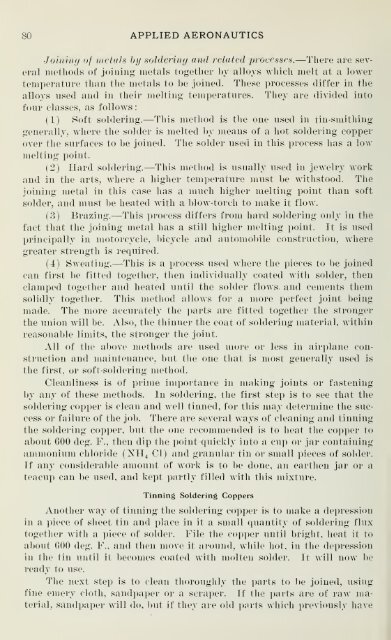

:80 APPLIED AERONAUTICSJoininf/ of metals hi/ soldering and related jyrocesses.—There are severalmethods of joining metals toge<strong>the</strong>r by allovs which melt at a lowertemperature thau <strong>the</strong> metals to be joined. These processes differ in tliealloys used and in tlieir melting temperatures. They are divided intofour classes, as follows(1) Soft soldering.—This method is <strong>the</strong> one used in tin-smithinggenerally, where <strong>the</strong> solder is melted by means of a hot soldering copperover <strong>the</strong> surfaces to be joined. The solder used in this process has a lowmelting point.(2) Hard soldering.—This method is usually used in jewelry workand in <strong>the</strong> arts, where a higher temperature must be withstood. Thejoining metal in this case has a much higher melting point than softsolder, and must be heated with a blow-torch to make it flow.(3) Brazing.—This process differs from hard soldering onh- in <strong>the</strong>fact that <strong>the</strong> joining metal has a still higher melting point. It is usedprincipally in motorcycle, bicycle and automobile construction, wheregreater strength isrequired.(4) Sweating.—This is a process used where <strong>the</strong> pieces to be joinedcan first be fitted toge<strong>the</strong>r, <strong>the</strong>n individually coated with solder, <strong>the</strong>nclamped toge<strong>the</strong>r and heated until <strong>the</strong> solder flows, and cements <strong>the</strong>msolidly toge<strong>the</strong>r. This method allows for a more perfect joint beingmade. The more accurately <strong>the</strong> parts are fitted toge<strong>the</strong>r <strong>the</strong> stronger<strong>the</strong> union will be. Also, <strong>the</strong> thinner <strong>the</strong> coat of soldering material, withinreasonable limits, <strong>the</strong> stronger <strong>the</strong> joint.All of <strong>the</strong> above methods are used more or less in <strong>airplane</strong> constructionand maintenance, but <strong>the</strong> one that is most generally used is<strong>the</strong> first, or soft-soldering method.Cleanliness is of prime importance in making joints or fasteningby any of <strong>the</strong>se methods. In soldering, <strong>the</strong> first step is to see that <strong>the</strong>soldering copper is clean and well tinned, for this may determine <strong>the</strong> successor failure of <strong>the</strong> job.There are several ways of cleaning and tinning<strong>the</strong> soldering copper, but <strong>the</strong> one recommended is to heat <strong>the</strong> copper toabout 600 deg. F., <strong>the</strong>n dip <strong>the</strong> point quickly into a cup or jar containingammonium chloride (NH4 CI) and granular tin or small pieces of solder.If any considerable amount of work is to be done, an ear<strong>the</strong>n jar or ateacup can be used, and kept partly filled with this mixture.Tinning Soldering CoppersAno<strong>the</strong>r way of tinning <strong>the</strong> soldering copper is to make a depressionin a piece of sheet tin and place in ita small quantity of soldering fluxtoge<strong>the</strong>r with a piece of solder. File <strong>the</strong> copper until bright, heat it toabout 600 deg. F., and <strong>the</strong>n move it around, while hot, in <strong>the</strong> depressionin <strong>the</strong> tin until it becomes coated with molten solder. It will now beready to use.The next step is to clean thoroughly <strong>the</strong> parts to be joined, usingfine emery cloth, sandpaper or a scraper. If <strong>the</strong> parts are of raw material,sandpaper will do, but if <strong>the</strong>y are old parts which previously have