Model R7F4DH HLS Remote I/O Module - M-System

Model R7F4DH HLS Remote I/O Module - M-System

Model R7F4DH HLS Remote I/O Module - M-System

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

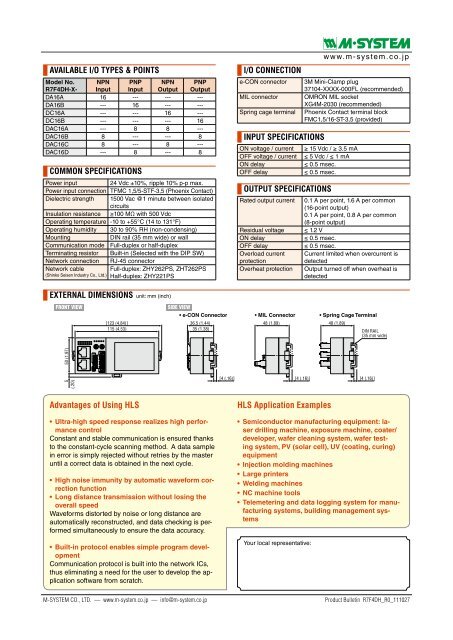

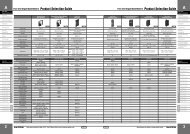

AVAILABLE I/O TYPES & POINTS<strong>Model</strong> No.<strong>R7F4DH</strong>-X-NPNInputPNPInputNPNOutputPNPOutputDA16A 16 --- --- ---DA16B --- 16 --- ---DC16A --- --- 16 ---DC16B --- --- --- 16DAC16A --- 8 8 ---DAC16B 8 --- --- 8DAC16C 8 --- 8 ---DAC16D --- 8 --- 8COMMON SPECIFICATIONSPower input24 Vdc ±10%, ripple 10% p-p max.Power input connection TFMC 1,5/5-STF-3,5 (Phoenix Contact)Dielectric strength 1500 Vac @1 minute between isolatedcircuitsInsulation resistance ≥100 MΩ with 500 VdcOperating temperature -10 to +55°C (14 to 131°F)Operating humidity 30 to 90% RH (non-condensing)MountingDIN rail (35 mm wide) or wallCommunication mode Full-duplex or half-duplexTerminating resistor Built-in (Selected with the DIP SW)Network connection RJ-45 connectorNetwork cable(Shinko Seisen Industry Co., Ltd.)Full-duplex: ZHY262PS, ZHT262PSHalf-duplex: ZHY221PSI/O CONNECTIONe-CON connectorMIL connectorSpring cage terminalINPUT SPECIFICATIONSON voltage / currentOFF voltage / currentON delayOFF delayOUTPUT SPECIFICATIONSRated output currentResidual voltageON delayOFF delayOverload currentprotectionOverheat protectionwww.m-system.co.jp3M Mini-Clamp plug37104-XXXX-000FL (recommended)OMRON MIL socketXG4M-2030 (recommended)Phoenix Contact terminal blockFMC1,5/16-ST-3,5 (provided)≥ 15 Vdc / ≥ 3.5 mA≤ 5 Vdc / ≤ 1 mA≤ 0.5 msec.≤ 0.5 msec.0.1 A per point, 1.6 A per common(16-point output)0.1 A per point, 0.8 A per common(8-point output)≤ 1.2 V≤ 0.5 msec.≤ 0.5 msec.Current limited when overcurrent isdetectedOutput turned off when overheat isdetectedEXTERNAL DIMENSIONS unit: mm (inch)FRONT VIEWSIDE VIEW[123 (4.84)]36.5 (1.44)115 (4.53) 35 (1.38)• e-CON Connector • MIL Connector • Spring Cage Terminal48 (1.89)48 (1.89)DIN RAIL(35 mm wide)50 (1.97)5(.20)[4 (.16)][4 (.16)][4 (.16)]Advantages of Using <strong>HLS</strong><strong>HLS</strong> Application Examples• Ultra-high speed response realizes high performancecontrolConstant and stable communication is ensured thanksto the constant-cycle scanning method. A data samplein error is simply rejected without retries by the masteruntil a correct data is obtained in the next cycle.• High noise immunity by automatic waveform correctionfunction• Long distance transmission without losing theoverall speedWaveforms distorted by noise or long distance areautomatically reconstructed, and data checking is performedsimultaneously to ensure the data accuracy.• Built-in protocol enables simple program developmentCommunication protocol is built into the network ICs,thus eliminating a need for the user to develop the applicationsoftware from scratch.• Semiconductor manufacturing equipment: laserdrilling machine, exposure machine, coater/developer, wafer cleaning system, wafer testingsystem, PV (solar cell), UV (coating, curing)equipment• Injection molding machines• Large printers• Welding machines• NC machine tools• Telemetering and data logging system for manufacturingsystems, building management systemsYour local representative:M-SYSTEM CO., LTD. — www.m-system.co.jp — info@m-system.co.jpProduct Bulletin <strong>R7F4DH</strong>_R0_111027