pre-fabricated at a single site for distribution to manydifferent locations. <strong>The</strong> advantages <strong>of</strong> this method is thata specialised facility using fast, modern productiontechniques can produce panels with varying designparameters, rapidly <strong>and</strong> in great numbers. <strong>The</strong>economies <strong>of</strong> scale <strong>of</strong> such plant mean that theproduction costs are very low for each unit area <strong>of</strong>structure. This methodology is well suited to the casewhere small ship yards require <strong>SPS</strong> components to beincluded in a new vessel, or specialist fabricatorsbuilding accommodation blocks, hatch covers <strong>and</strong> othership components for delivery as complete blocks tolarger ship yards.In the second option larger areas <strong>of</strong> <strong>SPS</strong> structure arefabricated <strong>and</strong> injected with polymer as an integratedprocess on the production line. A typical ship productionfacility would use a process similar to the following:• Steel plates are cleaned <strong>and</strong> prepared as required <strong>and</strong>brought to the production line where they are joinedusing automated welding to create large panels.• <strong>The</strong> large panels are moved along the line to a pointwhere secondary stiffeners are introduced, positioned<strong>and</strong> welded to the plating. Although automatedwelding techniques are employed, this process can bevery lengthy due to the sheer number <strong>of</strong> secondarystiffeners <strong>and</strong> the amount <strong>of</strong> welding to be deposited.• Once the secondary stiffeners are attached, primarystructures (e.g. floors, webs, girders <strong>and</strong> stringers)which have already been prepared with openings <strong>and</strong>cut-outs for the secondary stiffeners are introduced tothe production line. <strong>The</strong>se are attached to the largeplate panel using automated welding, but in additionthe intersections <strong>of</strong> the primary <strong>and</strong> secondarystructure need to be carefully welded in a sequencewhich minimises the risk <strong>of</strong> distortions <strong>and</strong> residualstresses. This is a very time consuming part <strong>of</strong> theproduction process <strong>and</strong> one where great attention toquality is required. Not only do the intersectionscreate difficult areas for automated welding to beused, but lugs <strong>and</strong> collars can add complexity <strong>and</strong>time to the process.• Once the primary structure is added, the panelsbecome 3D sub-assemblies which can then be erected<strong>and</strong> assembled into larger blocks ready for erectinginto the main ship structure.In integrating <strong>SPS</strong> into a production line similar to theabove, the process will be modified as follows.• Steel plates are cleaned <strong>and</strong> prepared as required <strong>and</strong>brought to the production line where they are joinedusing automated welding to create large panels thatwill form either the inner or outer <strong>SPS</strong> face plate.• <strong>The</strong> inner <strong>SPS</strong> face plate is moved along the line tothe point where primary structures (e.g. floors, webs,girders <strong>and</strong> stringers) which have already beenprepared with access openings <strong>and</strong> cut-outs fordrainage, are introduced to the production line. Nosecondary stiffeners are required, eliminating manymetres <strong>of</strong> welding <strong>and</strong> the complexity <strong>of</strong>intersections.• <strong>The</strong> outer <strong>SPS</strong> face plate is moved along the line tothe point where the perimeter bars are welded to theedges <strong>of</strong> the plate <strong>and</strong> <strong>SPS</strong> spacers are added toprovide the necessary control over the core depth.Once this process is complete, the inner <strong>SPS</strong> faceplate (complete with primary structure) is placed overthe outer <strong>SPS</strong> face plate <strong>and</strong> welded to the perimeterbars to form an air-tight cavity ready for theelastomer injection.• <strong>The</strong> complete panel is moved along the line to the“injection bay” where the panel is injected withelastomer resin. Care is needed at this point tocontrol the temperature <strong>of</strong> the panel during the curingstage <strong>of</strong> the elastomer <strong>and</strong> also to restrain the panelsas described above.<strong>The</strong> above are only outline descriptions <strong>of</strong> the processes<strong>and</strong> do not enter into detail, but the important point isthat the <strong>SPS</strong> production process eliminates the timeconsuming step <strong>of</strong> introducing the secondary stiffeners<strong>and</strong> the associated intersections with primary structure.Initial estimates have indicated that the amount <strong>of</strong> timespent in attaching secondary stiffeners may be as high asdouble that required to complete the steps involving <strong>SPS</strong>cavity forming <strong>and</strong> elastomer injection. This can save upto 8 hours elapsed time in the production <strong>of</strong> a singlepanel sub-assembly.6. INSPECTION AND MAINTENANCE<strong>The</strong> simplified structures made possible with <strong>SPS</strong>technology <strong>of</strong>fer benefits for inspection <strong>and</strong> maintenance.<strong>The</strong> ballast tanks <strong>of</strong> conventional double hull tankershave significant internal structure, <strong>of</strong>ten with manythous<strong>and</strong>s <strong>of</strong> intersections.A principal concern for double hull tankers is theapplication, inspection <strong>and</strong> maintenance <strong>of</strong> coatings inthe ballast tanks. In the 14k products tanker exampleoutlined in Section 3, the reduced surface area <strong>of</strong> coatingrepresents approximately 20% <strong>of</strong> the ballast tank internalarea. <strong>The</strong> elimination <strong>of</strong> secondary stiffeners also meansthe elimination <strong>of</strong> edges <strong>and</strong> corners where coating breakdown is initiated.Inspection <strong>of</strong> inner hull spaces is very time consuming,due to the cellular nature <strong>of</strong> the space <strong>and</strong> the necessity<strong>of</strong> inspecting the intersections. This <strong>of</strong>ten requiresclimbing over each longitudinal stiffener <strong>and</strong> having toinspect under flanges using torches. Where coatingbreakdown is found, it is necessary to note the location;<strong>and</strong> remedial action can be laborious, time consuming<strong>and</strong> expensive. <strong>SPS</strong> structures are inherently less costlyto apply original coatings, less susceptible to coatingbreakdown <strong>and</strong> easier to inspect <strong>and</strong> re-coat.10

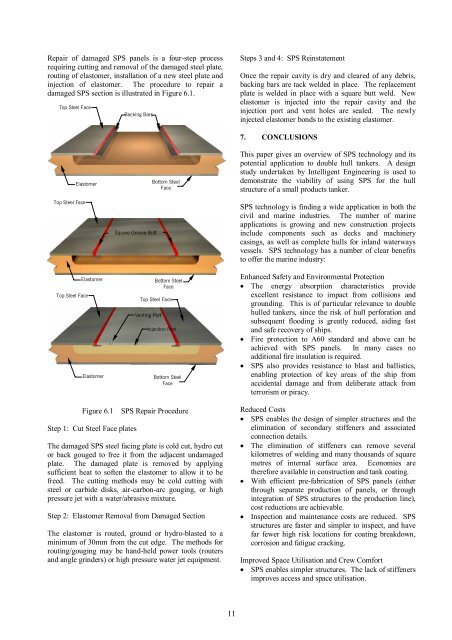

Repair <strong>of</strong> damaged <strong>SPS</strong> panels is a four-step processrequiring cutting <strong>and</strong> removal <strong>of</strong> the damaged steel plate,routing <strong>of</strong> elastomer, installation <strong>of</strong> a new steel plate <strong>and</strong>injection <strong>of</strong> elastomer. <strong>The</strong> procedure to repair adamaged <strong>SPS</strong> section is illustrated in Figure 6.1.Top Steel FaceBacking BarsSteps 3 <strong>and</strong> 4: <strong>SPS</strong> ReinstatementOnce the repair cavity is dry <strong>and</strong> cleared <strong>of</strong> any debris,backing bars are tack welded in place. <strong>The</strong> replacementplate is welded in place with a square butt weld. Newelastomer is injected into the repair cavity <strong>and</strong> theinjection port <strong>and</strong> vent holes are sealed. <strong>The</strong> newlyinjected elastomer bonds to the existing elastomer.ElastomerTop Steel FaceElastomerTop Steel FaceElastomerSquare Groove ButtBottom SteelFaceBottom SteelFaceTop Steel FaceVenting PortInjection PortBottom SteelFace7. CONCLUSIONSThis paper gives an overview <strong>of</strong> <strong>SPS</strong> technology <strong>and</strong> itspotential application to double hull tankers. A designstudy undertaken by Intelligent Engineering is used todemonstrate the viability <strong>of</strong> using <strong>SPS</strong> for the hullstructure <strong>of</strong> a small products tanker.<strong>SPS</strong> technology is finding a wide application in both thecivil <strong>and</strong> marine industries. <strong>The</strong> number <strong>of</strong> marineapplications is growing <strong>and</strong> new construction projectsinclude components such as decks <strong>and</strong> machinerycasings, as well as complete hulls for inl<strong>and</strong> waterwaysvessels. <strong>SPS</strong> technology has a number <strong>of</strong> clear benefitsto <strong>of</strong>fer the marine industry:Enhanced <strong>Safety</strong> <strong>and</strong> Environmental Protection• <strong>The</strong> energy absorption characteristics provideexcellent resistance to impact from collisions <strong>and</strong>grounding. This is <strong>of</strong> particular relevance to doublehulled tankers, since the risk <strong>of</strong> hull perforation <strong>and</strong>subsequent flooding is greatly reduced, aiding fast<strong>and</strong> safe recovery <strong>of</strong> ships.• Fire protection to A60 st<strong>and</strong>ard <strong>and</strong> above can beachieved with <strong>SPS</strong> panels. In many cases noadditional fire insulation is required.• <strong>SPS</strong> also provides resistance to blast <strong>and</strong> ballistics,enabling protection <strong>of</strong> key areas <strong>of</strong> the ship fromaccidental damage <strong>and</strong> from deliberate attack fromterrorism or piracy.Figure 6.1 <strong>SPS</strong> Repair ProcedureStep 1: Cut Steel Face plates<strong>The</strong> damaged <strong>SPS</strong> steel facing plate is cold cut, hydro cutor back gouged to free it from the adjacent undamagedplate. <strong>The</strong> damaged plate is removed by applyingsufficient heat to s<strong>of</strong>ten the elastomer to allow it to befreed. <strong>The</strong> cutting methods may be cold cutting withsteel or carbide disks, air-carbon-arc gouging, or highpressure jet with a water/abrasive mixture.Step 2: Elastomer Removal from Damaged Section<strong>The</strong> elastomer is routed, ground or hydro-blasted to aminimum <strong>of</strong> 30mm from the cut edge. <strong>The</strong> methods forrouting/gouging may be h<strong>and</strong>-held power tools (routers<strong>and</strong> angle grinders) or high pressure water jet equipment.Reduced Costs• <strong>SPS</strong> enables the design <strong>of</strong> simpler structures <strong>and</strong> theelimination <strong>of</strong> secondary stiffeners <strong>and</strong> associatedconnection details.• <strong>The</strong> elimination <strong>of</strong> stiffeners can remove severalkilometres <strong>of</strong> welding <strong>and</strong> many thous<strong>and</strong>s <strong>of</strong> squaremetres <strong>of</strong> internal surface area. Economies aretherefore available in construction <strong>and</strong> tank coating.• With efficient pre-fabrication <strong>of</strong> <strong>SPS</strong> panels (eitherthrough separate production <strong>of</strong> panels, or throughintegration <strong>of</strong> <strong>SPS</strong> structures to the production line),cost reductions are achievable.• Inspection <strong>and</strong> maintenance costs are reduced. <strong>SPS</strong>structures are faster <strong>and</strong> simpler to inspect, <strong>and</strong> havefar fewer high risk locations for coating breakdown,corrosion <strong>and</strong> fatigue cracking.Improved Space Utilisation <strong>and</strong> Crew Comfort• <strong>SPS</strong> enables simpler structures. <strong>The</strong> lack <strong>of</strong> stiffenersimproves access <strong>and</strong> space utilisation.11