The Performance, Safety and Production Benefits of SPS Structures ...

The Performance, Safety and Production Benefits of SPS Structures ...

The Performance, Safety and Production Benefits of SPS Structures ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

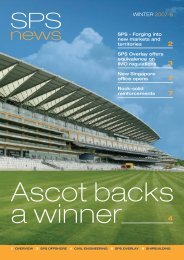

Other performance characteristics that have beenestablished <strong>and</strong> quantified include:• Fatigue resistance (S-N curves) <strong>of</strong> the interface bond<strong>and</strong> welded connection details specifically developedto join prefabricated <strong>SPS</strong> plates (refer to FigureA.2(a)).• Salt water <strong>and</strong> chemical resistance <strong>of</strong> the elastomercore should it become exposed during the life <strong>of</strong> thestructure. Figure A.2(b) shows test samples fromone <strong>of</strong> four test series where sets <strong>of</strong> 30mm elastomercubes were completely immersed in typical chemicalspecies.• Vibration damping <strong>and</strong> structural borne noisetransmission Figure A.2(c) illustrates typicaldisplacement attenuation curves for <strong>SPS</strong> <strong>and</strong> steelplates subject to a single pulse. <strong>The</strong> inset pictureillustrates a st<strong>and</strong>ard vibration characterisation testconducted at BASF laboratories in Ludwigshafen.• Ballistic resistance limits for stiffened steel <strong>and</strong> <strong>SPS</strong>plates (all-steel <strong>and</strong> bi-metal) subject to st<strong>and</strong>ard7.62mm rounds are illustrated in Figure A.2(d). <strong>The</strong>setests were conducted by QINETIQ (formally DERA).FIRE RESISTANCE AND ENGINEERING<strong>SPS</strong> has exceptional resistance to fire. It is an extremelyeffective barrier to heat, flame, smoke <strong>and</strong> toxic gases. Itwill contain a fire <strong>and</strong> prevent it spreading to adjacentcompartments, greatly limiting the growth <strong>of</strong> a firethroughout a structure. This has been demonstrated byan extensive series <strong>of</strong> full-scale deck panel <strong>and</strong> bulkheadtests, conducted in accordance with IMO (SOLAS)st<strong>and</strong>ards at independent fire laboratories. <strong>The</strong> MaritimeCoastguard Agency (MCA) co-developed the fire safetytest programme <strong>and</strong> has witnessed <strong>SPS</strong> fire tests. FigureA.3(a) shows the st<strong>and</strong>ard SOLAS stiffened steel deckpanel without structural fire protection. <strong>The</strong> plate isseverely distorted <strong>and</strong> the maximum surface temperatureincrease on the unexposed surface is +713ºC. <strong>The</strong> surfacetemperature on <strong>SPS</strong> plate with structural fire protection,shown in Figure A.3(b), is +3ºC. <strong>The</strong> correspondingtemperature on an insulated steel plate was +192ºC.(b) <strong>SPS</strong> 8-40-8 deck plateFigure A.3 <strong>Safety</strong> <strong>of</strong> Life at Sea – Enhanced FireResistance<strong>The</strong> steel face plates present a fully non-combustiblebarrier to a fire that may occur from either side <strong>and</strong> theelastomer core provides an extremely effective insulatoragainst heat from fires. If an <strong>SPS</strong> panel is directlyexposed to fire for an extended period then the elastomercore acts as sacrificial layer on the fire side (ablation)<strong>and</strong> gases from the elastomer surface vent into the fireside through temperature controlled pressure releasevalves. Only the exposed elastomer surface layer isaffected, the remaining elastomer <strong>and</strong> the elastomer-steelbonded surface on the unexposed surface are unaffected.<strong>SPS</strong> can provide greater insulation than conventionalarrangements. After the st<strong>and</strong>ard 60-minute fire test(945ºC at one hour), the average temperature increase onthe unexposed surface <strong>of</strong> a <strong>SPS</strong> 4-25-4 plate withoutstructural fire protection was 96ºC. <strong>The</strong> correspondingincrease for a <strong>SPS</strong> 8-40-8 plate was 24ºC. For an A-60barrier, SOLAS requires this increase to be no greaterthan 140ºC. With <strong>SPS</strong> plates the unexposed surfaceremains cooler longer, extending containment <strong>of</strong> the fire,<strong>and</strong> allowing more time for people to escape <strong>and</strong> firefighters to fight the fire. Based on the experimentalevidence <strong>and</strong> fire engineering analyses conducted withthe University <strong>of</strong> Strathclyde, the MCA has submitted thefollowing information papers to the IMO on theperformance <strong>and</strong> behaviour <strong>of</strong> <strong>SPS</strong> when subjected t<strong>of</strong>ire loads.• Equivalence <strong>of</strong> a New Composite Structural Materialto Steel in Maritime <strong>Structures</strong> <strong>SPS</strong> (S<strong>and</strong>wich PlateSystem), Maritime <strong>Safety</strong> Committee 74 th session,2001• Fire Equivalence <strong>of</strong> SOLAS Chapter II-2 for theS<strong>and</strong>wich Plate System (<strong>SPS</strong>), Sub-committee onFire Protection 47 th session, 2002(a) stiffened steel plate15