The Performance, Safety and Production Benefits of SPS Structures ...

The Performance, Safety and Production Benefits of SPS Structures ...

The Performance, Safety and Production Benefits of SPS Structures ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

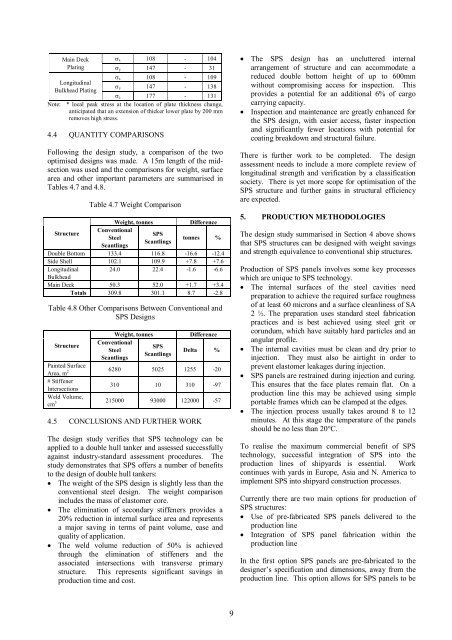

Main Deck σ x 108 - 104Plating σ y 147 - 31σ x 108 - 109Longitudinalσ y 147 - 138Bulkhead Platingσ e 177 - 131Note: * local peak stress at the location <strong>of</strong> plate thickness change,anticipated that an extension <strong>of</strong> thicker lower plate by 200 mmremoves high stress.4.4 QUANTITY COMPARISONSFollowing the design study, a comparison <strong>of</strong> the twooptimised designs was made. A 15m length <strong>of</strong> the midsectionwas used <strong>and</strong> the comparisons for weight, surfacearea <strong>and</strong> other important parameters are summarised inTables 4.7 <strong>and</strong> 4.8.StructureTable 4.7 Weight ComparisonWeight, tonnesConventionalSteelScantlings<strong>SPS</strong>ScantlingsDifferencetonnes %Double Bottom 133.4 116.8 -16.6 -12.4Side Shell 102.1 109.9 +7.8 +7.6Longitudinal24.0 22.4 -1.6 -6.6BulkheadMain Deck 50.3 52.0 +1.7 +3.4Totals 309.8 301.1 8.7 -2.8Table 4.8 Other Comparisons Between Conventional <strong>and</strong><strong>SPS</strong> DesignsStructureWeight, tonnesConventionalSteelScantlings<strong>SPS</strong>ScantlingsDifferenceDelta %Painted SurfaceArea, m 2 6280 5025 1255 -20# StiffenerIntersections310 10 310 -97Weld Volume,cm 3 215000 93000 122000 -574.5 CONCLUSIONS AND FURTHER WORK<strong>The</strong> design study verifies that <strong>SPS</strong> technology can beapplied to a double hull tanker <strong>and</strong> assessed successfullyagainst industry-st<strong>and</strong>ard assessment procedures. <strong>The</strong>study demonstrates that <strong>SPS</strong> <strong>of</strong>fers a number <strong>of</strong> benefitsto the design <strong>of</strong> double hull tankers:• <strong>The</strong> weight <strong>of</strong> the <strong>SPS</strong> design is slightly less than theconventional steel design. <strong>The</strong> weight comparisonincludes the mass <strong>of</strong> elastomer core.• <strong>The</strong> elimination <strong>of</strong> secondary stiffeners provides a20% reduction in internal surface area <strong>and</strong> representsa major saving in terms <strong>of</strong> paint volume, ease <strong>and</strong>quality <strong>of</strong> application.• <strong>The</strong> weld volume reduction <strong>of</strong> 50% is achievedthrough the elimination <strong>of</strong> stiffeners <strong>and</strong> theassociated intersections with transverse primarystructure. This represents significant savings inproduction time <strong>and</strong> cost.• <strong>The</strong> <strong>SPS</strong> design has an uncluttered internalarrangement <strong>of</strong> structure <strong>and</strong> can accommodate areduced double bottom height <strong>of</strong> up to 600mmwithout compromising access for inspection. Thisprovides a potential for an additional 6% <strong>of</strong> cargocarrying capacity.• Inspection <strong>and</strong> maintenance are greatly enhanced forthe <strong>SPS</strong> design, with easier access, faster inspection<strong>and</strong> significantly fewer locations with potential forcoating breakdown <strong>and</strong> structural failure.<strong>The</strong>re is further work to be completed. <strong>The</strong> designassessment needs to include a more complete review <strong>of</strong>longitudinal strength <strong>and</strong> verification by a classificationsociety. <strong>The</strong>re is yet more scope for optimisation <strong>of</strong> the<strong>SPS</strong> structure <strong>and</strong> further gains in structural efficiencyare expected.5. PRODUCTION METHODOLOGIES<strong>The</strong> design study summarised in Section 4 above showsthat <strong>SPS</strong> structures can be designed with weight savings<strong>and</strong> strength equivalence to conventional ship structures.<strong>Production</strong> <strong>of</strong> <strong>SPS</strong> panels involves some key processeswhich are unique to <strong>SPS</strong> technology.• <strong>The</strong> internal surfaces <strong>of</strong> the steel cavities needpreparation to achieve the required surface roughness<strong>of</strong> at least 60 microns <strong>and</strong> a surface cleanliness <strong>of</strong> SA2 ½. <strong>The</strong> preparation uses st<strong>and</strong>ard steel fabricationpractices <strong>and</strong> is best achieved using steel grit orcorundum, which have suitably hard particles <strong>and</strong> anangular pr<strong>of</strong>ile.• <strong>The</strong> internal cavities must be clean <strong>and</strong> dry prior toinjection. <strong>The</strong>y must also be airtight in order toprevent elastomer leakages during injection.• <strong>SPS</strong> panels are restrained during injection <strong>and</strong> curing.This ensures that the face plates remain flat. On aproduction line this may be achieved using simpleportable frames which can be clamped at the edges.• <strong>The</strong> injection process usually takes around 8 to 12minutes. At this stage the temperature <strong>of</strong> the panelsshould be no less than 20°C.To realise the maximum commercial benefit <strong>of</strong> <strong>SPS</strong>technology, successful integration <strong>of</strong> <strong>SPS</strong> into theproduction lines <strong>of</strong> shipyards is essential. Workcontinues with yards in Europe, Asia <strong>and</strong> N. America toimplement <strong>SPS</strong> into shipyard construction processes.Currently there are two main options for production <strong>of</strong><strong>SPS</strong> structures:• Use <strong>of</strong> pre-fabricated <strong>SPS</strong> panels delivered to theproduction line• Integration <strong>of</strong> <strong>SPS</strong> panel fabrication within theproduction lineIn the first option <strong>SPS</strong> panels are pre-fabricated to thedesigner’s specification <strong>and</strong> dimensions, away from theproduction line. This option allows for <strong>SPS</strong> panels to be9