The Performance, Safety and Production Benefits of SPS Structures ...

The Performance, Safety and Production Benefits of SPS Structures ...

The Performance, Safety and Production Benefits of SPS Structures ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

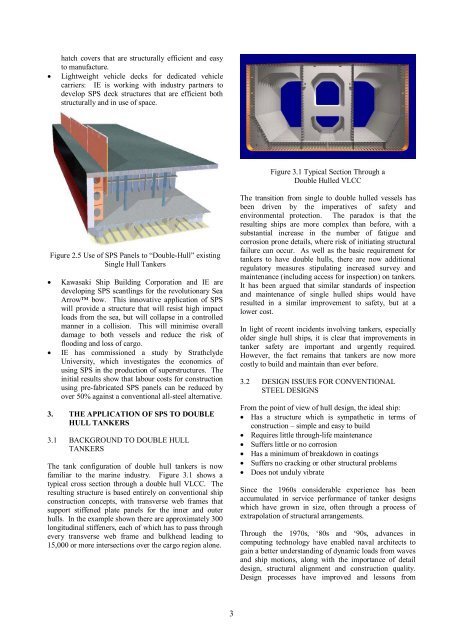

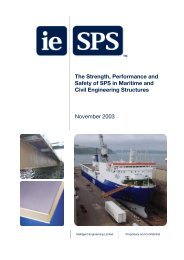

hatch covers that are structurally efficient <strong>and</strong> easyto manufacture.• Lightweight vehicle decks for dedicated vehiclecarriers: IE is working with industry partners todevelop <strong>SPS</strong> deck structures that are efficient bothstructurally <strong>and</strong> in use <strong>of</strong> space.Figure 3.1 Typical Section Through aDouble Hulled VLCCFigure 2.5 Use <strong>of</strong> <strong>SPS</strong> Panels to “Double-Hull” existingSingle Hull Tankers• Kawasaki Ship Building Corporation <strong>and</strong> IE aredeveloping <strong>SPS</strong> scantlings for the revolutionary SeaArrow bow. This innovative application <strong>of</strong> <strong>SPS</strong>will provide a structure that will resist high impactloads from the sea, but will collapse in a controlledmanner in a collision. This will minimise overalldamage to both vessels <strong>and</strong> reduce the risk <strong>of</strong>flooding <strong>and</strong> loss <strong>of</strong> cargo.• IE has commissioned a study by StrathclydeUniversity, which investigates the economics <strong>of</strong>using <strong>SPS</strong> in the production <strong>of</strong> superstructures. <strong>The</strong>initial results show that labour costs for constructionusing pre-fabricated <strong>SPS</strong> panels can be reduced byover 50% against a conventional all-steel alternative.3. THE APPLICATION OF <strong>SPS</strong> TO DOUBLEHULL TANKERS3.1 BACKGROUND TO DOUBLE HULLTANKERS<strong>The</strong> tank configuration <strong>of</strong> double hull tankers is nowfamiliar to the marine industry. Figure 3.1 shows atypical cross section through a double hull VLCC. <strong>The</strong>resulting structure is based entirely on conventional shipconstruction concepts, with transverse web frames thatsupport stiffened plate panels for the inner <strong>and</strong> outerhulls. In the example shown there are approximately 300longitudinal stiffeners, each <strong>of</strong> which has to pass throughevery transverse web frame <strong>and</strong> bulkhead leading to15,000 or more intersections over the cargo region alone.<strong>The</strong> transition from single to double hulled vessels hasbeen driven by the imperatives <strong>of</strong> safety <strong>and</strong>environmental protection. <strong>The</strong> paradox is that theresulting ships are more complex than before, with asubstantial increase in the number <strong>of</strong> fatigue <strong>and</strong>corrosion prone details, where risk <strong>of</strong> initiating structuralfailure can occur. As well as the basic requirement fortankers to have double hulls, there are now additionalregulatory measures stipulating increased survey <strong>and</strong>maintenance (including access for inspection) on tankers.It has been argued that similar st<strong>and</strong>ards <strong>of</strong> inspection<strong>and</strong> maintenance <strong>of</strong> single hulled ships would haveresulted in a similar improvement to safety, but at alower cost.In light <strong>of</strong> recent incidents involving tankers, especiallyolder single hull ships, it is clear that improvements intanker safety are important <strong>and</strong> urgently required.However, the fact remains that tankers are now morecostly to build <strong>and</strong> maintain than ever before.3.2 DESIGN ISSUES FOR CONVENTIONALSTEEL DESIGNSFrom the point <strong>of</strong> view <strong>of</strong> hull design, the ideal ship:• Has a structure which is sympathetic in terms <strong>of</strong>construction – simple <strong>and</strong> easy to build• Requires little through-life maintenance• Suffers little or no corrosion• Has a minimum <strong>of</strong> breakdown in coatings• Suffers no cracking or other structural problems• Does not unduly vibrateSince the 1960s considerable experience has beenaccumulated in service performance <strong>of</strong> tanker designswhich have grown in size, <strong>of</strong>ten through a process <strong>of</strong>extrapolation <strong>of</strong> structural arrangements.Through the 1970s, ‘80s <strong>and</strong> ‘90s, advances incomputing technology have enabled naval architects togain a better underst<strong>and</strong>ing <strong>of</strong> dynamic loads from waves<strong>and</strong> ship motions, along with the importance <strong>of</strong> detaildesign, structural alignment <strong>and</strong> construction quality.Design processes have improved <strong>and</strong> lessons from3