FLENDER gear units - DS TECH

FLENDER gear units - DS TECH

FLENDER gear units - DS TECH

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

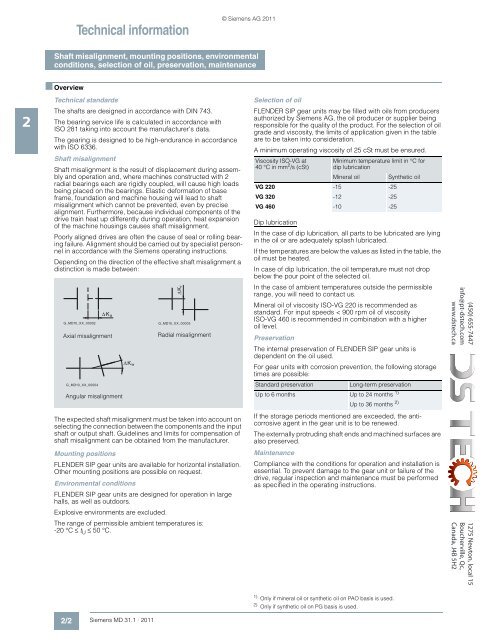

Technical information© Siemens AG 2011Shaft misalignment, mounting positions, environmentalconditions, selection of oil, preservation, maintenance■ OverviewTechnical standardsSelection of oil2The shafts are designed in accordance with DIN 743.The bearing service life is calculated in accordance withISO 281 taking into account the manufacturer's data.The <strong>gear</strong>ing is designed to be high-endurance in accordancewith ISO 6336.Shaft misalignmentShaft misalignment is the result of displacement during assemblyand operation and, where machines constructed with 2radial bearings each are rigidly coupled, will cause high loadsbeing placed on the bearings. Elastic deformation of baseframe, foundation and machine housing will lead to shaftmisalignment which cannot be prevented, even by precisealignment. Furthermore, because individual components of thedrive train heat up differently during operation, heat expansionof the machine housings causes shaft misalignment.Poorly aligned drives are often the cause of seal or rolling bearingfailure. Alignment should be carried out by specialist personnelin accordance with the Siemens operating instructions.Depending on the direction of the effective shaft misalignment adistinction is made between:<strong>FLENDER</strong> SIP <strong>gear</strong> <strong>units</strong> may be filled with oils from producersauthorized by Siemens AG, the oil producer or supplier beingresponsible for the quality of the product. For the selection of oilgrade and viscosity, the limits of application given in the tableare to be taken into consideration.A minimum operating viscosity of 25 cSt must be ensured.Viscosity ISO-VG at40 °C in mm 2 /s (cSt)Dip lubricationMinimum temperature limit in °C fordip lubricationMineral oilVG 220 -15 -25VG 320 -12 -25VG 460 -10 -25Synthetic oilIn the case of dip lubrication, all parts to be lubricated are lyingin the oil or are adequately splash lubricated.If the temperatures are below the values as listed in the table, theoil must be heated.In case of dip lubrication, the oil temperature must not dropbelow the pour point of the selected oil. Axial misalignmentRadial misalignmentIn the case of ambient temperatures outside the permissiblerange, you will need to contact us.Mineral oil of viscosity ISO-VG 220 is recommended asstandard. For input speeds < 900 rpm oil of viscosityISO-VG 460 is recommended in combination with a higheroil level.PreservationThe internal preservation of <strong>FLENDER</strong> SIP <strong>gear</strong> <strong>units</strong> isdependent on the oil used.(450) 655-7447info@pt-dstech.comwww.dstech.ca For <strong>gear</strong> <strong>units</strong> with corrosion prevention, the following storagetimes are possible:Angular misalignmentStandard preservationLong-term preservationUp to 6 months Up to 24 months 1)Up to 36 months 2)The expected shaft misalignment must be taken into account onselecting the connection between the components and the inputshaft or output shaft. Guidelines and limits for compensation ofshaft misalignment can be obtained from the manufacturer.If the storage periods mentioned are exceeded, the anticorrosiveagent in the <strong>gear</strong> unit is to be renewed.The externally protruding shaft ends and machined surfaces arealso preserved.Mounting positions<strong>FLENDER</strong> SIP <strong>gear</strong> <strong>units</strong> are available for horizontal installation.Other mounting positions are possible on request.Environmental conditions<strong>FLENDER</strong> SIP <strong>gear</strong> <strong>units</strong> are designed for operation in largehalls, as well as outdoors.MaintenanceCompliance with the conditions for operation and installation isessential. To prevent damage to the <strong>gear</strong> unit or failure of thedrive, regular inspection and maintenance must be performedas specified in the operating instructions.Explosive environments are excluded.The range of permissible ambient temperatures is:-20 °C ≤ t U ≤ 50 °C.1275 Newton, local 15Boucherville, Qc,Canada, J4B 5H21) Only if mineral oil or synthetic oil on PAO basis is used.2) Only if synthetic oil on PG basis is used.2/2 Siemens MD 31.1 · 2011