FLENDER gear units - DS TECH

FLENDER gear units - DS TECH

FLENDER gear units - DS TECH

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

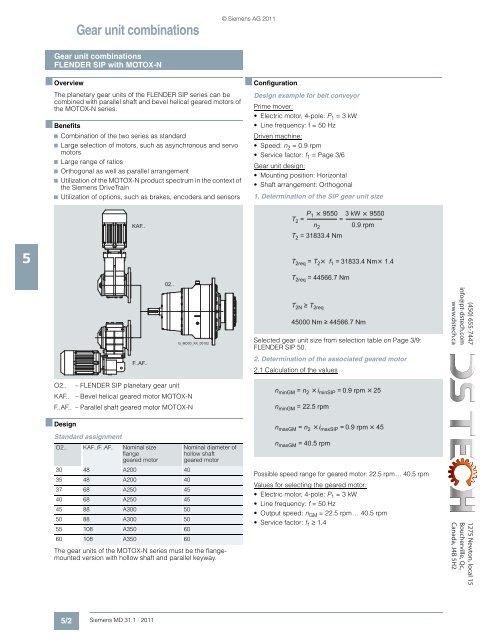

Gear unit combinations© Siemens AG 2011Gear unit combinations<strong>FLENDER</strong> SIP with MOTOX-N■ OverviewThe planetary <strong>gear</strong> <strong>units</strong> of the <strong>FLENDER</strong> SIP series can becombined with parallel shaft and bevel helical <strong>gear</strong>ed motors ofthe MOTOX-N series.■ Benefits7 Combination of the two series as standard7 Large selection of motors, such as asynchronous and servomotors7 Large range of ratios7 Orthogonal as well as parallel arrangement7 Utilization of the MOTOX-N product spectrum in the context ofthe Siemens DriveTrain7 Utilization of options, such as brakes, encoders and sensors■ ConfigurationDesign example for belt conveyorPrime mover:•Electric motor, 4-pole: P 1 = 3 kW•Line frequency: f = 50 HzDriven machine:•Speed: n 2 = 0.9 rpm• Service factor: f 1 = Page 3/6Gear unit design:•Mounting position: Horizontal•Shaft arrangement: Orthogonal1. Determination of the SIP <strong>gear</strong> unit sizeKAF..P 1 9550 3 kW 9550T 2 ==n 2 0.9 rpmT 2 = 31833.4 Nm5T 2req = T 2 f 1 = 31833.4 Nm 1.402..G_MD30_XX_00102T 2req = 44566.7 NmT 2N ≥ T 2req45000 Nm ≥ 44566.7 NmSelected <strong>gear</strong> unit size from selection table on Page 3/9:<strong>FLENDER</strong> SIP 50.(450) 655-7447info@pt-dstech.comwww.dstech.caF..AF..O2.. – <strong>FLENDER</strong> SIP planetary <strong>gear</strong> unitKAF.. – Bevel helical <strong>gear</strong>ed motor MOTOX-NF..AF.. – Parallel shaft <strong>gear</strong>ed motor MOTOX-N2. Determination of the associated <strong>gear</strong>ed motor2.1 Calculation of the valuesn minGM = n 2 i minSIP = 0.9 rpm 25n minGM = 22.5 rpm■ DesignStandard assignmentO2.. KAF../F..AF.. Nominal sizeflange<strong>gear</strong>ed motor30 48 A200 4035 48 A200 4037 68 A250 4540 68 A250 4545 88 A300 5050 88 A300 5055 108 A350 6060 108 A350 60Nominal diameter ofhollow shaft<strong>gear</strong>ed motorThe <strong>gear</strong> <strong>units</strong> of the MOTOX-N series must be the flangemountedversion with hollow shaft and parallel keyway.n maxGM = n 2 i maxSIP = 0.9 rpm 45n maxGM = 40.5 rpmPossible speed range for <strong>gear</strong>ed motor: 22.5 rpm… 40.5 rpmValues for selecting the <strong>gear</strong>ed motor:•Electric motor, 4-pole: P 1 = 3 kW•Line frequency: f = 50 Hz•Output speed: n GM = 22.5 rpm… 40.5 rpm•Service factor: f 1 ≥ 1.41275 Newton, local 15Boucherville, Qc,Canada, J4B 5H25/2 Siemens MD 31.1 · 2011