Bituthene® 2000 Pre-formed Self-adhesive Rubber Bitumen/High ...

Bituthene® 2000 Pre-formed Self-adhesive Rubber Bitumen/High ...

Bituthene® 2000 Pre-formed Self-adhesive Rubber Bitumen/High ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

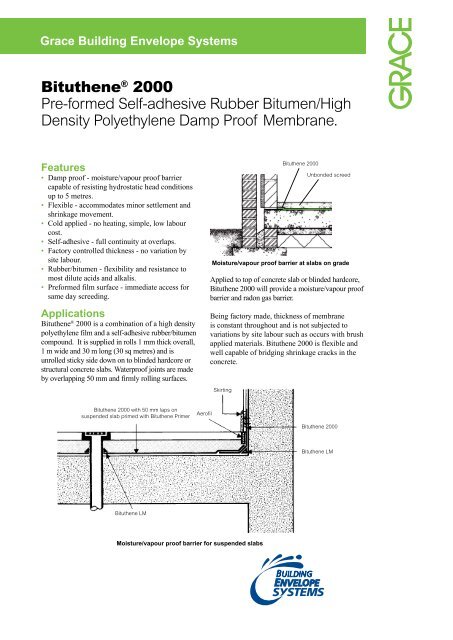

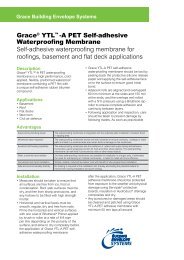

Grace Building Envelope SystemsBituthene ® <strong>2000</strong><strong>Pre</strong>-<strong>formed</strong> <strong>Self</strong>-<strong>adhesive</strong> <strong>Rubber</strong> <strong>Bitumen</strong>/<strong>High</strong>Density Polyethylene Damp Proof Membrane.Features•Damp proof - moisture/vapour proof barriercapable of resisting hydrostatic head conditionsup to 5 metres.Flexible - accommodates minor settlement andshrinkage movement.Cold applied - no heating, simple, low labourcost.<strong>Self</strong>-<strong>adhesive</strong> - full continuity at overlaps.Factory controlled thickness - no variation bysite labour.<strong>Rubber</strong>/bitumen - flexibility and resistance tomost dilute acids and alkalis.<strong>Pre</strong><strong>formed</strong> film surface - immediate access forsame day screeding.••••••ApplicationsBituthene ® <strong>2000</strong> is a combination of a high densitypolyethylene film and a self-<strong>adhesive</strong> rubber/bitumencompound. It is supplied in rolls 1 mm thick overall,1 m wide and 30 m long (30 sq metres) and isunrolled sticky side down on to blinded hardcore orstructural concrete slabs. Waterproof joints are madeby overlapping 50 mm and firmly rolling surfaces.Applied to top of concrete slab or blinded hardcore,Bituthene <strong>2000</strong> will provide a moisture/vapour proofbarrier and radon gas barrier.Being factory made, thickness of membraneis constant throughout and is not subjected tovariations by site labour such as occurs with brushapplied materials. Bituthene <strong>2000</strong> is flexible andwell capable of bridging shrinkage cracks in theconcrete.SkirtingBituthene <strong>2000</strong>Unbonded screedMoisture/vapour proof barrier at slabs on gradeBituthene <strong>2000</strong> with 50 mm laps onsuspended slab primed with Bituthene PrimerAerofilBituthene <strong>2000</strong>Bituthene LMBituthene LMMoisture/vapour proof barrier for suspended slabs

PerformanceBituthene <strong>2000</strong> - typical performance propertiesProperty Typical Values Test MethodColour Dark Grey/Black N/ATensile Strength (film only) 40,000 kN/m 2 ASTM D882Tape Strength 5.10 N/mm ASTM D412Elongation of membrane(to ultimate failure of rubberised asphalt)150% ASTM D412Lap adhesion @ 23°C 648 N/m ASTM D1876Puncture resistance >220N ASTM E154Resistance to Hydrostatic head 60 m ASTM D5385Tear resistance 32 N/mm ASTM D624Permeance 1.6 ng/m 2 .s.Pa ASTM E96 [12]Typical Test Values may represent average values from samples tested. Test Methods noted may be modified.SupplyBituthene <strong>2000</strong> 1 m x 30 m roll (30 sq m)Weight 40 kg grossStorageStore upright in dry conditionsbelow +35°CAncillary MaterialsBituthene PrimerCoverageBituthene MasticBituthene LM18 litre pails6 ~ 8 sq metre per litre dependingon method of application, surfacetexture, porosity and ambienttemperature850cc cartridges,3 litre can5.7 litre pailsInstallationConcrete slab or concrete blinded hardcore shall besurface dry, free from standing water, and laid to a regularsurface free from sharp protrusions and hollows. Verticalfaces shall be smooth, regular, dry and free from nailsand primed with one coat of Bituthene Primer appliedby brush or roller, at a rate depending on the porosity ofthe surface and allowed to dry before the application ofthe Bituthene <strong>2000</strong>. Brickwork must be flush pointed orrendered to provide a smooth surface. Bituthene <strong>2000</strong>shall be laid by peeling back the protective release paperand applying the <strong>adhesive</strong> face on to the prepared surface.The material should be brushed on to the surface toexclude air. Adjacent rolls are aligned and overlapped 50mm minimum at side and ends and well rolled with a firmpressure using a Bituthene Lap Roller to ensure completedadhesion and continuity between the layers. A guidelineis printed on the membrane. Following the applicationcare should be taken to prevent damage by followingtrades. Damaged areas can be repaired by patching withan oversize patch applied to a clean dry surface and firmlyrolled.Health and SafetyRefer to relevant Material Health and Safety data sheets.Quality AssuranceW. R. Grace (Singapore) Pte Ltd is certified to ISO9002 Quality Systems by SISIR (Singapore Institute ofStandard & Industrial Research) for the manufacture ofBituthene Waterproofing Membranes under the registeredcertification number ISO 93-2-0269.SpecificationBituthene <strong>2000</strong> pre<strong>formed</strong> membrane shall be laid on tosmooth concrete surface, or concrete blinded hardcoreby applying the pre<strong>formed</strong> membrane, sticky sidedownwards to give well rolled 50 mm overlaps, laidstrictly in accordance with the manufacturer’s instructionsand supplied by Grace Construction Products. For furtherinformation, contact your local Grace representative.Grace Technical ServicesFor assistance with working drawings for projectsand additional technical advice, please contactGrace Technical Services.www.graceconstruction.comAustralia: Brisbane (61-7) 3277 7244 Hong Kong (852) 2675 7898 Japan (81-3) 5405 2991Korea (82-32) 820 0800 Mainland China: Beijing (86-10) 6786 3488, Guangzhou (86-20) 3833 0775,Shanghai (86-21) 5467 4678 Singapore (65) 6265 3033 Taiwan (886-3) 461 5462 Thailand (66-2) 709 4470Vietnam: Ho Chi Minh City (84-8)7106 168Bituthene is a registered trademark of W. R. Grace & Co.-Conn.The information given is based on data and knowledge considered to be true and accurate and is offered for the user’s consideration,investigation and verification. Since the conditions of use are beyond our control we do not warrant the results to be obtained. Pleaseread all statements, recommendations or suggestions in conjunction with our conditions of sale including those limiting warranties andremedies which apply to all goods supplied by us. No statement, recommendation or suggestion is intended for any use which wouldviolate or infringe statutory obligations or any rights belonging to a third party.These products may be covered by patents or patents pending. Copyright 2007. W. R. Grace (S) Pte Ltd 110-BIT-9A Printed in Singapore 11/07