Monokote® Z-146PC High Density, Petrochemical Grade ...

Monokote® Z-146PC High Density, Petrochemical Grade ...

Monokote® Z-146PC High Density, Petrochemical Grade ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

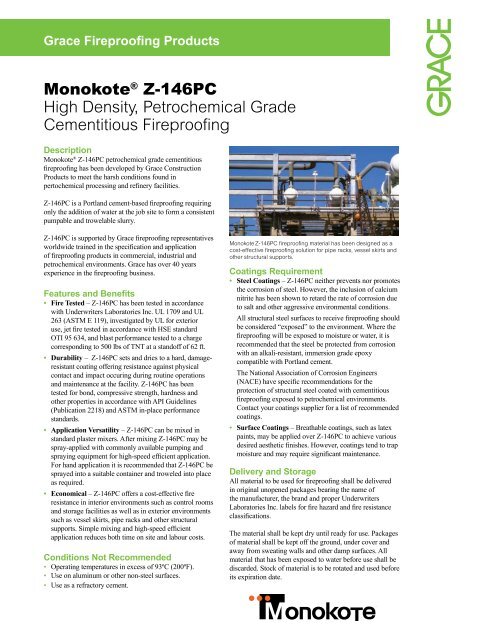

Grace Fireproofing ProductsMonokote ® Z-<strong>146PC</strong><strong>High</strong> <strong>Density</strong>, <strong>Petrochemical</strong> <strong>Grade</strong>Cementitious FireproofingDescriptionMonokote ® Z-<strong>146PC</strong> petrochemical grade cementitiousfireproofing has been developed by Grace ConstructionProducts to meet the harsh conditions found inpertochemical processing and refinery facilities.Z-<strong>146PC</strong> is a Portland cement-based fireproofing requiringonly the addition of water at the job site to form a consistentpumpable and trowelable slurry.Z-<strong>146PC</strong> is supported by Grace fireproofing representativesworldwide trained in the specification and applicationof fireproofing products in commercial, industrial andpetrochemical environments. Grace has over 40 yearsexperience in the fireproofing business.Features and Benefits• Fire Tested – Z-<strong>146PC</strong> has been tested in accordancewith Underwriters Laboratories Inc. UL 1709 and UL263 (ASTM E 119), investigated by UL for exterioruse, jet fire tested in accordance with HSE standardOTI 95 634, and blast performance tested to a chargecorresponding to 500 lbs of TNT at a standoff of 62 ft.• Durability – Z-<strong>146PC</strong> sets and dries to a hard, damageresistantcoating offering resistance against physicalcontact and impact occuring during routine operationsand maintenance at the facility. Z-<strong>146PC</strong> has beentested for bond, compressive strength, hardness andother properties in accordance with API Guidelines(Publication 2218) and ASTM in-place performancestandards.• Application Versatility – Z-<strong>146PC</strong> can be mixed instandard plaster mixers. After mixing Z-<strong>146PC</strong> may bespray-applied with commonly available pumping andspraying equipment for high-speed efficient application.For hand application it is recommended that Z-<strong>146PC</strong> besprayed into a suitable container and troweled into placeas required.• Economical – Z-<strong>146PC</strong> offers a cost-effective fireresistance in interior environments such as control roomsand storage facilities as well as in exterior environmentssuch as vessel skirts, pipe racks and other structuralsupports. Simple mixing and high-speed efficientapplication reduces both time on site and labour costs.Conditions Not Recommended• Operating temperatures in excess of 93ºC (200ºF).• Use on aluminum or other non-steel surfaces.• Use as a refractory cement.Monokote Z-<strong>146PC</strong> fireproofing material has been designed as acost-effective fireproofing solution for pipe racks, vessel skirts andother structural supports.Coatings Requirement• Steel Coatings – Z-<strong>146PC</strong> neither prevents nor promotesthe corrosion of steel. However, the inclusion of calciumnitrite has been shown to retard the rate of corrosion dueto salt and other aggressive environmental conditions.All structural steel surfaces to receive fireproofing shouldbe considered “exposed” to the environment. Where thefireproofing will be exposed to moisture or water, it isrecommended that the steel be protected from corrosionwith an alkali-resistant, immersion grade epoxycompatible with Portland cement.The National Association of Corrosion Engineers(NACE) have specific recommendations for theprotection of structural steel coated with cementitiousfireproofing exposed to petrochemical environments.Contact your coatings supplier for a list of recommendedcoatings.• Surface Coatings – Breathable coatings, such as latexpaints, may be applied over Z-<strong>146PC</strong> to achieve variousdesired aesthetic finishes. However, coatings tend to trapmoisture and may require significant maintenance.Delivery and StorageAll material to be used for fireproofing shall be deliveredin original unopened packages bearing the name ofthe manufacturer, the brand and proper UnderwritersLaboratories Inc. labels for fire hazard and fire resistanceclassifications.The material shall be kept dry until ready for use. Packagesof material shall be kept off the ground, under cover andaway from sweating walls and other damp surfaces. Allmaterial that has been exposed to water before use shall bediscarded. Stock of material is to be rotated and used beforeits expiration date.

Performance CharacteristicsPhysical Properties Recommended Specifications Test Method/Notes** Laboratory Tested* ValueDry density Min. 40 pcf (640 kg/m 3 ) ASTM E605 See note below ***Bond strength Min. 10,000 psf (478 kN/m 3 ) ASTM E736 17,967 psf (857 kN/m 2 )Compressive strength @ 10%deformation500 psi (3.45 MPa) ASTM E761 541 psi (3.73 MPa)Hardness 40 ASTM D2240 49Yield – Theoretical maximum 16.7 board feet(1.55 m 2 at 25mm) per bagColour – Natural concrete grey -Volatile Organic Content (off gassing)at 50ºC organic compounds C6-C28Less than 1 PPMW(Part per million by weight)Dynamic headspace (Thermaldesorbtion gas chromatography) –mass spectrometry)Less than 1 PPMW(Below detectable limits)Leachable AmmoniaLess than 50 PPB50 nanograms/mgLeachable ion by ion chromatographyLess than 50 PPB(Below detectable limits)* Independent laboratory tested value. Report available upon request.** ASTM International test methods modified for bond strength and compressive strength, where required, for high density, high performance products.*** All in-place performance tests should be conducted at or below the minimum recommended specification density. Test reports here were conducted at39.6 pcf (635 kg/m 3 )InspectionPrior to the application of Z-<strong>146PC</strong>, an inspection shall be made todetermine that all substrates are acceptable to receive fireproofing.Substrates must be free of any substances that would impair theadhesion of the fireproofing. All substrates shall be compatible withPortland cement-based fireproofing.It is recommended that all substrates covered by fireproofing beroutinely inspected as part of an ongong facilities maintenanceprogram. Where materials have been removed for inspection,Grace should be consulted for proper patching procedures.MixingZ-<strong>146PC</strong> shall be mixed by machine in a conventional paddle typeor continuous mixer designed for cementitious fireproofing. Themixer shall be kept clean and free of all previously mixed material.The mixer speed shall be adjusted to the lowest speed which givesadequate blending of the material and mixer density of 835 - 945 kg/m 3(52 - 59 pcf).Using a suitable metering device and mixer, approximately 15L(4 U.S. gal) per bag shall be first added to the mixer as the bladesturn. Add Z-<strong>146PC</strong> and mix until the mix is lump-free with acreamy texture. Overmixing Z-<strong>146PC</strong> will reduce pumping rateand density.• Z-<strong>146PC</strong> can be sprayed directly to lathed steel substrates in oneor more passes. A spray gun with a properly sized orifice withspray shield, and air pressure at the nozzle of approximately 20psi (140 kN/m 2 ) will provide the correct hangability, density andappearance.• Z-<strong>146PC</strong> may also be first sprayed into a suitable container andthen trowel applied.TemperatureAn air and substrate temperature of 4.4ºC (40ºF) minimum shall bemaintained for 24 hours prior to application, during application andfor a minimum of 72 hours after application of Z-<strong>146PC</strong>. To obtainoptimal strength, Z-<strong>146PC</strong> should be moist cured for a minimum of72 hours and then be allowed to dry naturally.Safetya. Z-<strong>146PC</strong> is slippery when wet. Signs reading “SLIPPERYWHEN WET” should be posted in all areas in contact with wetfireproofing material. Anti-slip surfaces should be used on allworking surfaces.b. A Material Safety Data Sheet for Z-<strong>146PC</strong> is available. Pleasecontact your Grace representative.Application• Z-<strong>146PC</strong> material shall not be used if it contains partially set,frozen or caked material.• Z-<strong>146PC</strong> shall have a minimum average dry, in-place density of640 kg/m 3 (40 pcf).www.graceconstruction.comMainland China: Beijing (86-10) 6786 3488, Guangzhou (86-20) 3833 0775, Shanghai (86-21) 5467 4678Hong Kong (852) 2675 7898 Japan (81-3) 5405 2991 Korea (82-32) 820 0800Singapore (65) 6265 3033 Taiwan (886-3) 461 5461Monokote is a registered trademark of W R Grace & Co.-Conn.The information given is based on data and knowledge considered to be true and accurate and is offered for the user’s consideration,investigation and verification. Since the conditions of use are beyond our control we do not warrant the results to be obtained. Pleaseread all statements, recommendations or suggestions in conjunction with our conditions of sale including those limiting warranties andremedies which apply to all goods supplied by us. No statement, recommendation or suggestion is intended for any use which wouldviolate or infringe statutory obligations or any rights belonging to a third party.These products may be covered by patents or patents pending. Copyright 2007. W. R. Grace (S) Pte Ltd 200-146-2 Printed in Singapore 07/07