Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

2<br />

September 2005

Editorial<br />

SHIPBUILDING<br />

BALTEXPO - SPECIAL ISSUE<br />

September<br />

2005<br />

PUBLISHER<br />

Shipbuilding and Shipping Ltd.<br />

Na Ostrowiu 1 Street<br />

80-958 Gdañsk, Poland<br />

www.okretownictwo.pl<br />

ACCOUNT:<br />

ING Bank<br />

PL 1050 1764 1000 0018 0203 7869<br />

Chairman<br />

Editor-in-Chief:<br />

Grzegorz Landowski<br />

Phone +48 58 307 12 49<br />

Grzegorz.Landowski@okretownictwo.pl<br />

Subscription<br />

and advertisement:<br />

Aleksandra Dylejko<br />

Phone +48 58 307 15 54<br />

Aleksandra.Dylejko@okretownictwo.pl<br />

Secretary Office:<br />

Phone: +48 58 307 17 70<br />

Fax +48 58 307 12 56<br />

www.okretownictwo.pl<br />

Contributing authors:<br />

Miros³aw Jasiñski<br />

Grzegorz Landowski<br />

Piotr Stareñczak<br />

Jan Paszkowski<br />

Bart³omiej Pomierski<br />

Stanis³aw Szymczak<br />

Adam Œmigielski<br />

Pictures:<br />

Jakub Bogucki<br />

Piotr Stareñczak<br />

Kazimierz Gliszczyñski<br />

Northern Shipyard<br />

Remontowa S.A.<br />

Royal Arctic Line A/S<br />

Szczecin New Shipyard<br />

Adam WoŸniczka<br />

Design and DTP:<br />

S³awomir W³odarczyk<br />

Printing House:<br />

Spartan<br />

Poleska Street 25,<br />

81-321 Gdynia<br />

Poland<br />

September 2005<br />

Significant<br />

Ships<br />

According to well-informed sources, at the<br />

end of 2004 the number of ships of the commercial<br />

fleet worldwide amounted to 89 960<br />

totaling 633,3 million CGT. The average age of<br />

ships came to 22 years. At the same time, the<br />

world order book reached another all-time record<br />

of more than 90 million CGT. In 2004, shipyards<br />

worldwide delivered 1729 vessels, amounting<br />

to 25,5 million CGT, more than three quarters<br />

of which were produced by Asian shipbuilders.<br />

On the other hand, European yards<br />

recorded the strongest increase in new orders<br />

from 4 million CGT in 2003 to 6,8 million CGT<br />

in 2004. In the same year Polish yards had<br />

new orders for 51 ships totaling 1 088 744 CGT,<br />

34 of which were container ships.<br />

In 2004, the Polish yards delivered 25 ships<br />

of 448 684 CGT and the value of 754,7 million<br />

USD. Two of them were really significant. The<br />

RINA list of “Significant Ships of the Year 2004”<br />

mentioned the arctic container carrier Mary<br />

Arctica of Remontowa Group (see on page 7),<br />

and the multipurpose carrier Suomigracht (look<br />

at page 44) of Szczecin New Shipyard.<br />

At the end of 2004, the total portfolio<br />

of all Polish yards consisted of 95 ships<br />

of 2 112 617 CGT, and the contract value of<br />

3,620 million USD. However, a certain number<br />

of ships had been ordered two or three<br />

years ago. According to World Shipyard Monitor,<br />

at the end of March 2005, there were 4394<br />

ships of the total of 230,7 million dwt ordered<br />

worldwide. At the same time, the total order<br />

book of Polish yards amounted to 96 ships of<br />

2 024 983 CGT and the value of USD 3659,9<br />

million. Most orders have been placed with<br />

Gdynia Shipyard Group and Szczecin New<br />

Shipyard, however world sources (among them<br />

CESA) have also noticed an increasing role of<br />

Remontowa Group (Gdañsk Shiprepair Yard<br />

Remontowa and it’s subsidiary Northern Shipyard)<br />

in the Polish shipbuilding.<br />

„Polish-built Ships” is our presentation of<br />

some units ordered and delivered by the main<br />

Polish yards in 2004 and 2005, as well as some<br />

ships that are currently being under construction.<br />

Of course, we have not described all the<br />

ships coming from Polish yards, focusing our<br />

attention on completely equipped vessels only.<br />

In case of long series amounting from several<br />

to a dozen or so ships of one type we do not<br />

describe each particular vessel, unless we<br />

meet a prototype. Despite our efforts, a few<br />

yards refused to make technical data of some<br />

ships available to us. Finally, in some cases<br />

we do not even mention potential new orders<br />

that are still being negotiated.<br />

And what is more, this presentation is our<br />

choice. The selection of ships and projects that<br />

are, I believe, most significant for the Polish<br />

shipbuilding.<br />

GrzegorzLandowski@okretownictwo.pl<br />

3

Editorial<br />

Significant ships ................................. 3<br />

Order book<br />

of Polish yards .................................... 5<br />

Ships delivered<br />

and under construction ....................... 6<br />

REMONTOWA Group<br />

Gdañsk Shiprepair Yard Remontowa<br />

& Northern Shipyard<br />

Container carrier 572 TEU<br />

Mary Arctica ........................................ 7<br />

Car-passenger ferry Bute ................... 10<br />

Double-ended car-passenger<br />

ferry Bastø III ....................................... 12<br />

Anchor handling<br />

towing supply vessels ........................ 14<br />

Purse seiner trawler<br />

Teigenes ............................................. 16<br />

Shrimp trawler Tråsavik ...................... 17<br />

Crab trawler Teineskjær ..................... 18<br />

Rapid intervention vessel ................... 20<br />

Multi-function buoy tenders ................ 22<br />

400 Pax shuttle ferries ........................ 24<br />

Double-ended<br />

car-passenger ferry SKS 86 ............... 26<br />

Ice breaking emergency<br />

evacuation vessels ............................. 27<br />

New anchor handling<br />

towing supply vessels ........................ 28<br />

Gdynia Shipyard Group<br />

Gdynia Shipyard & Gdañsk Shipyard<br />

Multi-purpose and flexible<br />

ro-lo’s from Gdynia ............................. 30<br />

4<br />

The biggest “floating garages” ........... 32<br />

Norasia Valparaiso ............................. 34<br />

Short-sea car carrier ........................... 36<br />

Kota Perkasa ...................................... 38<br />

Naval Shipyard Gdynia<br />

NS-935 type fast patrol craft ............... 40<br />

Polar research ship<br />

Maria S. Merian .................................. 41<br />

List of companies and advertisements:<br />

Szczecin New Shipyard<br />

contents<br />

World’s<br />

largest stainless<br />

steel parcel tankers ............................ 42<br />

Multipurpose<br />

cargo vessels<br />

with sto-ro ........................................... 44<br />

Biggest box carriers<br />

from Szczecin ..................................... 46<br />

The longest series<br />

setting standards ................................ 47<br />

Modern short-sea<br />

freight 2800 lane metres<br />

ro-ro vessel ......................................... 48<br />

Conrad Shipyard<br />

A luxurious<br />

motor yacht ......................................... 49<br />

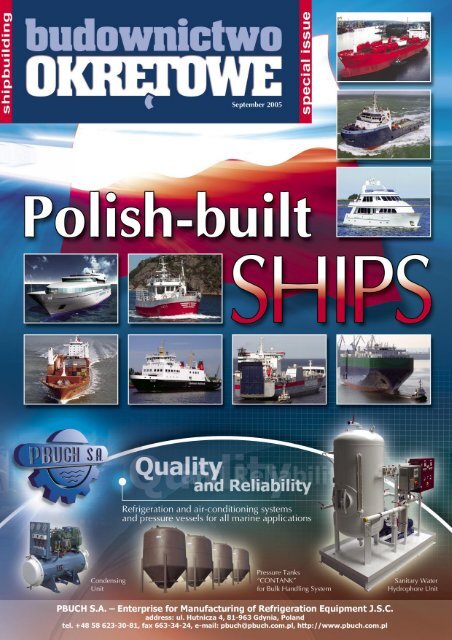

Enterprise for Manufacturing of Refrigeration Equipment PBUCH S.A. .............. 1<br />

MAN B&W Diesel A/S ........................................................................................... 2<br />

Ship Furniture Factory FAMOS Ltd. ...................................................................... 9<br />

Ships Machinery Works HYDROSTER Ltd. ......................................................... 13<br />

Enterprise for fire-fighting and protective equipment SUPON S.A. ..................... 15<br />

Light Fitting Manufacturer POLAM-REM S.A. ...................................................... 17<br />

Professional Marine Electronics FURUNO .......................................................... 19<br />

Gdansk Shiprepair Yard REMONTOWA S.A. ....................................................... 25<br />

ALSTOM Power Sp. z o.o. .................................................................................... 35<br />

Van Voorden Repair ............................................................................................. 37<br />

DMI Europe DV ..................................................................................................... 37<br />

AMI Exchangers Ltd. ............................................................................................ 37<br />

Technical Equipment Plant Co. GZUT S.A. .......................................................... 37<br />

Foreign Trade Corporation CENTROMOR S.A. .................................................. 39<br />

Naval Shipyard Gdynia ........................................................................................ 40, 41<br />

Marine Service Jaroszewicz ................................................................................ 43<br />

Conrad Shipyard S.A. ........................................................................................... 51<br />

Shipbuilding & Shipping Ltd. ................................................................................ 52<br />

September 2005

Order polish-build book ships of Polish yards<br />

ORDER BOOK OF SZCZECIN NEW SHIPYARD<br />

Type No B DWT TEU CGT Owner Delivery<br />

chemical tanker B588-III/5 39 850 - 23 972 Odfjell ASA 09.2005<br />

chemical tanker B588-III/6 39 850 - 23 972 Odfjell ASA 03.2006<br />

chemical tanker B588-III/7 39 850 - 23 972 Odfjell ASA 09.2006<br />

chemical tanker B588-III/8 39 850 - 23 972 Odfjell ASA 03.2007<br />

container carrier B178-I/14 41 850 3100 26 730 MS ZEUS Schiffahrtsgesellschaft GmbH&Co. KG 09.2005<br />

container carrier B178-I/15 41 850 3100 26 730 MS DEMETER Schiffahrtsgesellschaft GmbH&Co. KG 12.2005<br />

container carrier B178-I/16 41 850 3100 26 730 MS DAPHNE Schiffahrtsgesellschaft GmbH&Co. KG 03.2006<br />

container carrier B178-I/17 41 850 3100 26 730 MA LETO Schiffahrtsgesellschaft GmbH&Co. KG 07.2006<br />

container carrier B178-I/18 41 850 3100 26 730 MS HERA Schiffahrtsgesellschaft GmbH&Co. KG 10.2006<br />

container carrier B178-I/19 41 850 3100 26 730 Marquest Shipping Ltd. Cyprus 01.2007<br />

container carrier B178-I/20 41 850 3100 26 730 Hedwig Holding Ltd. Virgin Islands 04.2007<br />

container carrier B178-I/21 41 850 3100 26 730 MS HEBE Schiffahrtsgesellschaft GmbH&Co. KG 07.2008<br />

container carrier B178-I/22 41 850 3100 26 730 MS MAJA Schiffahrtsgesellschaft GmbH&Co. KG 11.2008<br />

container carrier B178-I/23 41 850 3100 26 730 Carpentine Ltd. Cyprus 03.2008<br />

container carrier B178-I/24 41 850 3100 26 730 Pendleton Ltd. Cyprus 06.2008<br />

container carrier B178-III/1 37 200 2800 24 000 Costa Container Lines, Italy 01.2007<br />

container carrier B178-III/2 37 200 2800 24 000 Costa Container Lines, Italy 04.2007<br />

container carrier B178-III/3 37 200 2800 24 000 Siebzehnte Reederei Neumuhlen GmbH&Cie KG, Germany 08.2007<br />

container carrier B178-III/4 37 200 2800 24 000 Achtzehnte Reederei Neumuhlen GmbH&Cie KG, Germany 10.2007<br />

container carrier B178-III/5 37 200 2800 24 000 Costa Container Lines, Italy 08.2008<br />

container carrier B178-III/6 37 200 2800 24 000 Costa Container Lines, Italy 12.2008<br />

container carrier B178-III/7 37 200 2800 24 000 Einunddreissigste Reederei Neumuhlen GmbH&Cie KG, Germany 02.2008<br />

container carrier B178-III/8 37 200 2800 24 000 Zweiunddreissigste Reederei Neumuhlen GmbH&Cie KG, Germany 05.2008<br />

container carrier B178-III/9 37 200 2800 24 000 Fesco Lines Hong Kong Ltd./Russia 04.2009<br />

container carrier B178-III/10 37 200 2800 24 000 Fesco Lines Hong Kong Ltd./Russia 04.2010<br />

container carrier B170-V/1 23 000 1730 13 440 Mar Space Shipping Co. Ltd. Cyprys/Russia 12.2007<br />

container carrier B170-V/2 23 000 1730 13 440 Light View Shipping Co. Ltd. Cyprys/Russia 02.2008<br />

container carrier B170-V/3 23 000 1730 13 440 Star Warm Shipping Co. Ltd. Cyprys/Russia 04.2008<br />

container carrier B170-V/4 23 000 1730 13 440 Costa Container Lines, Italy 10.2007<br />

container carrier B170-V/5 23 000 1730 13 440 Costa Container Lines, Italy 01.2009<br />

con-ro B201-II/1 18250 920 19 840 Spliethoff’s Bevrachtingskantoor BV 01.2006<br />

con-ro B201-II/2 18250 920 19 840 Spliethoff’s Bevrachtingskantoor BV 04.2006<br />

con-ro B201-II/3 18250 920 19 840 Spliethoff’s Bevrachtingskantoor BV 08.2006<br />

con-ro B201-II/4 18250 920 19 840 Spliethoff’s Bevrachtingskantoor BV 01.2007<br />

con-ro B201-II/5 18250 920 19 840 Spliethoff’s Bevrachtingskantoor BV 04.2007<br />

con-ro B201-II/6 18250 920 19 840 Spliethoff’s Bevrachtingskantoor BV 08.2007<br />

container carrier PP001/1,2 14 000 1210 14 400 Vinashin, Vietnam 11.2005<br />

ORDER BOOK OF GDYNIA SHIPYARD GROUP<br />

Type No B TEU DWT GT CGT Owner Builder<br />

car/truck carrier 6600 8168/12 - 21 300 57 700 33 688 Ray Car Carriers Ltd. Isle of Man Gdynia Shipyard<br />

car/truck carrier 6600 8168/13 - 21 300 57 700 33 688 Ray Car Carriers Ltd. Isle of Man Gdynia Shipyard<br />

car/truck carrier 6600 8168/14 - 21 300 57 700 33 688 Ray Car Carriers Ltd. Isle of Man Gdynia Shipyard<br />

car/truck carrier 6600 8168/15 - 21 300 57 700 33 688 Ray Car Carriers Ltd. Isle of Man Gdynia Shipyard<br />

car/truck carrier 6600 8168/16 - 21 300 57 700 33 688 Ray Car Carriers Ltd. Isle of Man Gdynia Shipyard<br />

car/truck carrier 6600 8168/17 - 21 300 57 700 33 688 Ray Car Carriers Ltd. Isle of Man Gdynia Shipyard<br />

car/truck carrier 6600 8168/18 - 21 300 57 700 33 688 Ray Car Carriers Ltd. Isle of Man Gdynia Shipyard<br />

car/truck carrier 6600 8168/19 - 21 300 57 700 33 688 Ray Car Carriers Ltd. Isle of Man Gdynia Shipyard<br />

car/truck carrier 6600 8168/20 - 21 300 57 700 33 688 Ray Car Carriers Ltd. Isle of Man Gdynia Shipyard<br />

container carrier 8184/9 2700 39 000 32 322 24 213 Passat Breeze Schiffahrtsgessellschaft mbH&Co. KG Germany Gdañsk Shipyard<br />

container carrier 8184/10 2700 39 000 32 322 24 213 Westertal Shipping GmbH&Co. KG Germany Gdañsk Shipyard<br />

container carrier 8184/11 2700 39 000 32 322 24 213 John Peter Wulff Schiffahrtsgessellschaft mbH&Co. KG Germany Gdynia Shipyard<br />

container carrier 8184/12 2700 39 000 32 322 24 213 Passat Spring Schiffahrtsgessellschaft mbH&Co. KG Germany Gdañsk Shipyard<br />

container carrier 8184/13 2700 39 000 32 322 24 213 Westermarsch Shipping GmbH&Co. KG Germany Gdynia Shipyard<br />

container carrier 8184/14 2700 39 000 32 322 24 213 John Peter Wulff Schiffahrtsgessellschaft mbH&Co. KG Germany Gdynia Shipyard<br />

container carrier 8184/15 2700 39 000 32 322 24 213 Passat Star Schiffahrtsgessellschaft mbH&Co. KG Germany Gdañsk Shipyard<br />

container carrier 8184/16 2700 39 000 32 322 24 213 Vasco da Gama Schiffahrtsgessellschaft mbH&Co. KG Germany Gdynia Shipyard<br />

container carrier 8184/17 2700 39 000 32 322 24 213 Amerigo Vespucci Schiffahrtsgessellschaft mbH&Co. KG Germany Gdynia Shipyard<br />

container carrier 8184/18 2700 39 000 32 322 24 213 Marco Polo Schiffahrtsgessellschaft mbH&Co. KG Germany Gdañsk Shipyard<br />

container carrier 8184/19 2700 39 000 32 322 24 213 Eirene Schiffahrtsgessellschaft mbH&Co. KG Germany Gdañsk Shipyard<br />

container carrier 8184/20 2700 39 000 32 322 24 213 Eunomia Polo Schiffahrtsgessellschaft mbH&Co. KG Germany Gdañsk Shipyard<br />

container carrier 8184/21 2700 39 000 32 322 24 213 Polaris Shipmanagement Co. Ltd. Isla of Man Gdynia Shipyard<br />

container carrier 8184/22 2700 39 000 32 322 24 213 Polaris Shipmanagement Co. Ltd. Isla of Man Gdynia Shipyard<br />

container carrier 8184/23 2700 39 000 32 322 24 213 Polaris Shipmanagement Co. Ltd. Isla of Man Gdynia Shipyard<br />

container carrier 8184/24 2700 39 000 32 322 24 213 John Peter Wulff Schiffahrtsgessellschaft mbH&Co. KG Germany Gdynia Shipyard<br />

container carrier 8184/25 2700 39 000 32 322 24 213 John Peter Wulff Schiffahrtsgessellschaft mbH&Co. KG Germany Gdynia Shipyard<br />

container carrier 8184/26 2700 39 000 32 322 24 213 Astraia Schiffahrtsgessellschaft mbH&Co. KG Germany Gdañsk Shipyard<br />

container carrier 8276/1 4530 57 000 51 350 34 536 Charlotte Wulf Schiffahrtsgessellschaft mbH&Co. KG Germany Gdynia Shipyard<br />

container carrier 8276/2 4530 57 000 51 350 34 536 Viktoria Wulf Schiffahrtsgessellschaft mbH&Co. KG Germany Gdynia Shipyard<br />

container carrier 8234/3 4420 57 000 51 350 34 536 Seven Seas Shipping GmbH&Co. KG Hamburg Gdynia Shipyard<br />

car/truck carrier 2000 8245/1 - 7 750 24 500 18 155 Ray Car Carriers Ltd. Isle of Man Gdynia Shipyard<br />

car/truck carrier 2000 8245/2 - 7 750 24 500 18 155 Ray Car Carriers Ltd. Isle of Man Gdynia Shipyard<br />

car/truck carrier 2000 8245/3 - 7 750 24 500 18 155 Ray Car Carriers Ltd. Isle of Man Gdynia Shipyard<br />

car/truck carrier 2000 8245/4 - 7 750 24 500 18 155 Ray Car Carriers Ltd. Isle of Man Gdynia Shipyard<br />

LPG gas carrier 78 500 8185/3 - 56 745 49 550 35 490 Ocean Gas Ltd, Isle of Man Gdynia Shipyard<br />

LPG gas carrier 78 500 8185/4 - 56 745 49 550 35 490 Ocean Gas Ltd, Isle of Man Gdynia Shipyard<br />

multi purpose 8228/5 - 45 000 31 772 23 622 Westwood Shipping Lines Inc. Federal Way Washington USA Gdynia Shipyard<br />

multi purpose 8228/6 - 45 000 31 772 23 622 Westwood Shipping Lines Inc. Federal Way Washington USA Gdynia Shipyard<br />

multi purpose 8228/7 - 45 000 31 772 23 622 Westwood Shipping Lines Inc. Federal Way Washington USA Gdynia Shipyard<br />

September 2005<br />

Source: Szczecin New Shipyard<br />

Source: Gdynia Shipyard<br />

5

SHIPS ORDERED/UNDER CONSTRUCTION AT REMONTOWA GROUP IN 2005<br />

6<br />

Ships delivered/under polish-build construction<br />

ships<br />

Name type No B Owner Delivery<br />

Alert rapid intervention vessel B 841/1 Trinity Lighthouse Service 01.2006<br />

- multi-function buoy tender 1453/I Northern Lighthouse Board 09.2006<br />

- multi-function buoy tender 1453/II Trinity Lighthouse Service 11.2006<br />

Folkestadt double ended/car passenger/ferry B 601/1 Nor-Ferjer/HSD Stavangerske 12.2005<br />

- ice braking emergency evacuation vessel B 843/1 Agip KCO 07.2006<br />

- ice braking emergency evacuation vessel B 843/2 Agip KCO 07.2006<br />

- ice braking emergency evacuation vessel B 843/3 Agip KCO 07.2006<br />

- ice braking emergency evacuation vessel B 843/4 Agip KCO 09.2006<br />

- anchor handling towing supply vessel B 844/1 Tidewater Marine LLC 05.2006<br />

- anchor handling towing supply vessel B 844/2 Tidewater Marine LLC 09.2006<br />

- ro-ro /car passenger ferrry 1333 B 338/1 Caledonian MacBrayne 08.2006<br />

- passenger ferry/1064/1 B 264/1 Moltzau/Sundbusserne 11.2006<br />

- passenger ferry/1064/2 B 264/2 Moltzau/Sundbusserne 12.2006<br />

- tuna fishing vessel B 337/2 Piriou 11.2005<br />

- tuna fishing vessel B 337/3 Piriou 03.2006<br />

SHIPS DELIVERED BY SZCZECIN NEW SHIPYARD IN 2005<br />

Source: Remontowa Group<br />

CGT Type Owner Delivery<br />

15 725 multi-purpose general vargo vessel Spliethoff's Bevrachtingskantoor BV 03.2005<br />

26 730 container carrier Schiffahrtsgesellschaft mbH & Co. KG Hamburg 04.2005<br />

23 972 chemical tanker Odfjell ASA 04.2005<br />

26 730 container carrier Schiffahrtsgesellschaft Oltmann Verwaltungs mbH 07.2005<br />

15 725 multi-purpose general vargo vessel Spliethoff's Bevrachtingskantoor BV 07.2005<br />

SHIPS DELIVERED BY GDYNIA SHIPYARD GROUP IN 2005<br />

Source: Szczecin New Shipyard<br />

Name Type DWT GT CGT Owner Delivery<br />

Poplar Arrow multi-purpose general cargo vessel 48 000 32 250 21 138 Gearbulk Holding, Hamilton, Bermuda 01.2005<br />

Morning Crown Pure car truck carrier 6600 21 300 57 700 31 735 Ray Car Carriers Ltd, Isle of Man 02.2005<br />

Morning Champion Pure car truck carrier 6600 21 300 57 700 31 735 Ray Car Carriers Ltd, Isle of Man 03.2005<br />

Punta Arenas Container carrier 2763 TEU 35 600 30 047 23 045 MS AMASIA Schiffahrtsgessellschaft GmbH&Co. KG 05.2005<br />

Morning Courier Pure car truck carrier 6600 21 300 57 700 31 735 Ray Car Carriers Ltd, Isle of Man 06.2005<br />

SHIPS DELIVERED BY REMONTOWA GROUP IN 2005<br />

Source: Gdynia Shipyard<br />

Name Type Number Owner Delivery<br />

Mary Arctica container carrier 1104/B Royal Arctic Line AS 03.2005<br />

Bastø III double-ended/car-passenger ferry B 241 Basto Fosen AS 02.2005<br />

J Hugh Roff anchor handling towing supply vessel B 244/1 Tidewater Marine LLC 01.2005<br />

Big Joe Tide anchor handling towing supply vessel B 244/2 Tidewater Marine LLC 05.2005<br />

Bute ro-ro /car passenger ferrry B 338/2 Caledonian MacBrayne 06.2005<br />

Teineskjær vivier crabber B 335/1 Teineskjær AS 04.2005<br />

Glenan tuna fishing vessel B 337/1 Piriou/Cobrecaf 07.2005<br />

Teigenes purse seiner trawler B 336/1 Teigenes AS 09.2005<br />

Trasåvik shrimp trawler B 334/1 Tråsavik ANS 09.2005<br />

Source: Remontowa Group<br />

September 2005

REMONTOWA Group<br />

CONTAINER CARRIER 572 TEU<br />

ary Arctica is a single screw vessel,<br />

with four holds, with superstructure<br />

and engineroom located<br />

aft, and with two deck cranes.<br />

The vessel’s purpose is the cargo carriage<br />

between the ports of Denmark and various<br />

harbours in Greenland.<br />

The ship has the highest ice class notation<br />

ICE 1A*. Apart from ice belt along<br />

the ship, plates in forward part are up to 30<br />

mm thick, and the stem plate – 50 mm. Additionally<br />

there is an ice knife above the<br />

rudder blade and ice fins in front of the propeller.<br />

In order to enable the ship to slide<br />

onto ice (to crush it with its own weight) the<br />

bow has the shape characteristic for ships<br />

sailing in polar regions.<br />

Mary Arctica is classed with DNV and<br />

her full class notation is +1A1, GENERAL<br />

CARGO/CONTAINER CARRIER, E0, ICS,<br />

DGP, ICE 1A* (in-water survey). Overall capacity<br />

of water ballast tanks is 6125 m3 ,<br />

fuel oil tanks (two biggest located in transverse<br />

bulkhead) have total volume of 1175<br />

m3 M<br />

. The ship is able to carry 259 20-ft containers<br />

in four box-shaped holds (equip-<br />

September 2005<br />

ped with cell guides) and 313 20-ft containers<br />

on deck and hatch covers. Sockets<br />

for 231 reefer containers were installed.<br />

Loading and unloading of containers<br />

in small Greenlandic harbours is possible<br />

MAIN PARTICULARS<br />

by means of two deck cranes located in the<br />

centreline of the vessel. They were delivered<br />

by Liebherr and have the maximum<br />

outreach of 29,8 m and SWL of 45 t.<br />

Two anchors of 19 t each, are serviced<br />

Contracted by Gdañsk Shiprepair Yard Remontowa S.A., Poland<br />

Built at / year Gdañsk Shipyard, Poland / 2005<br />

Yard No. 1104<br />

Flag/Home Port Danish (DIS) / Aalborg<br />

Delivered 03/2005<br />

Length overall 113,00 m<br />

Length b.p. 102,45 m<br />

Width 22,70 m<br />

Design draft 7,00 m<br />

Maximum container draft 7,50 m<br />

Scantling draft 8,20 m<br />

Gross Tonnage (GT) 10 300<br />

Net Tonnage (NT) 3093<br />

Deadweight for design draft 6365 t<br />

Deadweight for scantling draft 8870 t<br />

Height to main deck 15,15 m<br />

7

CONTAINER CAPACITY (TEU) ACCOMMODATION<br />

In holds 259<br />

On deck 313<br />

Total 572<br />

REEFER PLUGS<br />

In holds 133<br />

On deck 98<br />

Total 231<br />

Abt. 384 TEU at 14<br />

tons homogeneous<br />

TANK CAPACITY<br />

Fuel oil (100% full) 1175,8 m 3<br />

Diesel oil (100% full) 257,5 m 3<br />

Lub. oil (100% full) 146,4 m 3<br />

Fresh water 150,4 m 3<br />

Water ballast 6123,4 m 3<br />

by two, combined electric-driven anchormooring<br />

winches from Rolls-Royce. Additionally<br />

three mooring winches from the<br />

same maker were fitted. One Schilling-type<br />

GENERAL ARRANGEMENT<br />

8<br />

Officer 8<br />

Crew 7<br />

Pilot 1<br />

Hospital 1<br />

SPEED AND CONSUMPTION<br />

(90% MCR, 15% sea margin<br />

and 1000 kW on shaft generator)<br />

Service Speed 15,3 knots<br />

Fuel consumption per day<br />

Sailing HFO App. 31,0 tons<br />

In port MDO App. 3,0 tons<br />

rudder (from Becker Marine) is operated by<br />

two hydraulic, rotary, steering machines<br />

from Tenfjord Rolls-Royce.<br />

Propulsion is based on MAN B&W<br />

6S46MC-C main engine with MCR of 7860<br />

kW at 129 rpm. The engine has been produced<br />

by Cegielski (HCP) in Poland. Power<br />

is trasmitted (apart from 1600 kW shaft<br />

generator) to CPP of 5,1 m diameter. Power<br />

is also supplied from three gensets –<br />

REMONTOWA Group<br />

two of 735 kW at 900 rpm and one of 645<br />

kW at 900 rpm – all supplied by MAN B&W<br />

Holeby. One exhaust and one oil-fired boilers<br />

supply additional power. To assist<br />

ships’ manouvers in small harbours in Greenland<br />

two tunnel thrusters of 800 kW each<br />

were fitted.<br />

Life-saving equipment for 22 persons<br />

consists of one free-fall boat, one MOB boat<br />

and two life rafts for 25 persons each. There<br />

are also 22 working/survival suites allowing<br />

to survive a person in water for significantly<br />

extended time.<br />

Main components of navigation equipment<br />

are 2 radars (x- and S-band), 2 satelite<br />

navigation systems – DGPS and GPS,<br />

1 double gyro, 1 magnetic compass, autopilot<br />

and Voyage Data Recorder. This equipment,<br />

as well as radio equipment, has<br />

been supplied by Sperry Marine. Integreted<br />

ship control system has been supplied<br />

by Lyngsoe.<br />

Mary Arctica is the biggest vessel built<br />

at Remontowa S.A. The God Mother of the<br />

vessel is Her Royal Highness, Crown Princess<br />

Mary Elizabeth and this is a proof how<br />

important contract it was for Royal Arctic<br />

Line as well.<br />

September 2005

September 2005<br />

9

CAR-PASSENGER FERRY Bute<br />

Car – passenger ferry Bute, B 338/<br />

2, building number 1333/1 has<br />

been built at Northern Shipyard<br />

on order of Gdañsk Shiprepair<br />

Yard Remontowa S.A. for Scottish Owner<br />

Caledonian MacBrayne.<br />

Funding of up to 8,75 million pounds<br />

for a new ship for CalMac’s Rothesay/Wemyss<br />

Bay service – the Company’s busiest<br />

route – was announced late in 2003, by<br />

the Scottish Executive. According to UE<br />

rules the successful bidder had to be decided<br />

on a best value basis and as a result<br />

the contract went to the REMONTOWA<br />

Group in Poland.<br />

In the history of the Group, this ferryboat<br />

wasn’t the first of this type. However,<br />

this newbuilding has its own discriminant.<br />

For the first time the shipyard’s offer was<br />

not limited to the Scandinavian and British<br />

market including also the construction of<br />

the ferry-boat for the Scotch Owner. Moreover,<br />

the contract has provoked a lot of<br />

emotion and comments in Scotland. The<br />

Owner’s decision of committing the construction<br />

of the ferry-boat outside Scotland,<br />

10<br />

MAIN PARTICULARS<br />

REMONTOWA Group<br />

Contracted by Gdañsk Shiprepair Yard Remontowa SA<br />

Built at Northern Shipyard<br />

Length b.p. 67,75 m<br />

Length overall 72,01 m<br />

Breadth moulded 15,30 m<br />

Depth moulded to main deck 5,00 m<br />

Draught 3,00 m<br />

Frame spacing 600 mm<br />

Car capacity 66 PBE<br />

Passenger capacity 450<br />

Class Lloyds Class +100 A1, + LMC Ro-Ro Passenger<br />

and Vehicle Ferry with EP and IWS Notations. MCA Class IV&V.<br />

No of Crew 10<br />

Deadweight 400 t<br />

Gross tonnage 2612<br />

Contract Speed 14 knots<br />

Propulsion Two Main Engines Type MAK 6M20 rated at 1140 kW<br />

and 8M20 rated at 1520 kW both operating at 1000 rpm<br />

and driving Schottel Rudder Propellers type STP 1010<br />

and STP 121 forward and aft respectivey.<br />

Power Two Auxiliary Generators Type Scannia/Stamford each<br />

rated at 200 kW/250 kVA.<br />

Emergency Generator Type Sisu/Stamford<br />

rated at 120 kW/150 kVA.<br />

September 2005

REMONTOWA Group<br />

GENERAL ARRANGEMENT<br />

to the Polish shipyard was accepted with<br />

great surprise.<br />

The shipyard has built a ferry-boat<br />

which is small but modern with superstructure<br />

made of aluminium and innovatory<br />

engine room and shafting made of glass<br />

fibre. The whole design of the vessel was<br />

prepared in Shiprepair Yard’s Design Office,<br />

employed the most up to date technology<br />

including three – dimensional modelling<br />

techniques for steel and outfit production.<br />

One of the most interesting features<br />

of the project was the creation of a<br />

new ship model and it was, for example,<br />

while the ship was being planned, possible<br />

to “walk through” the engine room and<br />

accommodation to get impression of what<br />

September 2005<br />

the compartments would eventually look<br />

like.<br />

The new MV Bute is actually the seventh<br />

ship on the Clyde to have the name.<br />

MV Bute is 72 m long, 15,3 m in breadth<br />

and has a draught of 3 m. She will carry up<br />

to 60 cars, which compares with the 38 carried<br />

by Streakers currently operating on the<br />

Clyde. The ship will carry 450 passengers<br />

with seating provided internally for 250. She<br />

sails at 14 knots and has stabilisers.<br />

The ship’s design takes account of the<br />

needs of disabled customers and DPTAC<br />

guidelines. There is a lift with priority for<br />

the disabled and customers with impaired<br />

mobility. Priority car parking is also identified<br />

on the car deck. The whole operation<br />

from design to fulfilment is designed to enhance<br />

passenger safety, comfort, convenience<br />

and environmental performance.<br />

The vessel is equipped to carry 44 tonne<br />

vehicles and dangerous goods. She has<br />

roll-on/roll-off facilities with additional side<br />

loading ramp. Vessel engine controls,<br />

alarms and monitoring are carried from engineer’s<br />

control station on the bridge.<br />

The first cropping-out of steel plates destined<br />

for ferry-boat Bute took place on 2 nd<br />

August 2004, the ship was launched in February<br />

9, 2005 – sideways, and delivered<br />

the same year in June. She will be accompanied<br />

on the route in due course by a sister<br />

vessel which is due to enter service in<br />

2006.<br />

11

DOUBLE-ENDED<br />

CAR-PASSENGER FERRY Bastø III<br />

In February 2005 Bastø III ferry left for<br />

Norway. The ship had been built at Northern<br />

Shipyard, part of the REMONTO-<br />

WA Group, and delivered to Bastø Fosen<br />

A/S, its Norwegian owner.<br />

It has been the largest ferry built in the<br />

shipyards of the REMONTOWA Group so<br />

far, the largest of all ferries operating in the<br />

Norwegian fiords region, and the largest of<br />

the three ferries owned by Bastø Fosen A/<br />

S. It carries 550 passengers and 212 cars<br />

on the Horten – Moss route in the Oslofiord.<br />

Its crew consists of 15 persons. The<br />

length of the ship amounts to 116,2 m, its<br />

breadth to 19,5 m, and depth to 9,95 m.<br />

Gdañsk Shiprepair Yard Remontowa SA<br />

entered into a contract with a Norwegian<br />

owner, Bastø Fosen A/S, for building Basto<br />

III, the SKS 212 double-ended ferry, on 10<br />

July 2003. It meant winning the competition<br />

against 20 shipyards, including the<br />

Norwegian Fosen, Fiskerstrand and Brattvaag.<br />

The draft design was created by the<br />

Norwegian Kverndokk & Eldøy AS (KEAS).<br />

The ship was classified by Det Norske Veritas<br />

classification society.<br />

On 16 July 2004, the ship was launched<br />

sideways at Northern Shipyard without<br />

the upper part of its superstructure.<br />

Among other parts of the superstructure<br />

to be added at a later stage, also a wheelhouse<br />

was installed only after launching<br />

the ship.<br />

12<br />

MAIN PARTICULARS<br />

Length, oa 116.20 m<br />

Length, bp 99.60 m<br />

Length, car deck 106.60 m<br />

Breadth, mld 19.00 m<br />

Breadth, extreme 19.50 m<br />

Depth, mld, to main deck 5.60 m<br />

Depth, mld, to top deck 8.45 m<br />

Draught, extreme 5.00 m<br />

Frame spacing 0.60 m<br />

Tank capacity<br />

- fuel about 350 m 3<br />

- fresh water about 120 m 3<br />

Service speed 17 knots<br />

Gross tonnage about 6000 GT<br />

Passengers 550<br />

Freight-carrying capacity, cars 212<br />

Class notation: DnV + 1A1 – R4 – Ice C – Car Ferry A – Clean – E0<br />

Propeller, rudder and shaft Ice 1 B- Class.<br />

(plus additional BIS notation, informing of the hull marking<br />

as a means of preparing it for the inspection of its underwater part<br />

with no drydocking but on the water)<br />

The ship was built and equipped so as<br />

to observe requirements set by the following<br />

regulations:<br />

n NMD Regulations of 15.09.92 no. 695<br />

for building of passenger ship.<br />

n International convention for stability of<br />

life at sea, SOLAS 974/1987/1981/1983<br />

REMONTOWA Group<br />

n International Convention on Load Line.<br />

1966<br />

n International Tonnage Rules, 1969<br />

n International Convention for the Prevention<br />

of Pollution from Ships, 1973, Protocol<br />

of 1978 and amendment of 1984<br />

n Convention on the International Regu-<br />

September 2005

REMONTOWA Group<br />

lations for Preventing Collisions at Sea,<br />

1972 and amendment of 1983<br />

n Radio Regulations of the International<br />

Telecommunication Union 1974 and latest<br />

edition of 1982<br />

n Radio equipment according to GMDS-<br />

SA3<br />

Due to its big size as for a ship of this<br />

class, as well as to its long-route cruises,<br />

GENERAL ARRANGEMENT<br />

September 2005<br />

the ship was equipped with conventional<br />

propellers. Bastø III has two CP propellers<br />

and two rudder blades. The propulsion shafting<br />

system is installed virtually across all<br />

the ship right to the reduction gears and<br />

main drive engines amidships. The high<br />

blade lift rudders and steering gears were<br />

provided by Rolls-Royce, and the propulsion<br />

system (shaftlines, propellers, gears<br />

and main engines) by Wärtsilä. When wor-<br />

king on the design of the ship, noise and<br />

vibration analyses were carried out to trace<br />

and eliminate the focal areas of this kind<br />

of undesirable phenomena.<br />

There are two through-decks. The top<br />

deck is designed to carry heavy vehicles,<br />

whilst the main deck is a place for passenger<br />

cars. Providing an excellent field of vision,<br />

the superstructure together with the<br />

wheelhouse is to be found amidships.<br />

13

ANCHOR HANDLING<br />

J. Hugo Roff Jr. and Big Joe Tide are<br />

versatile vessels that combine continuous<br />

bollard pull of over 100 tones,<br />

designed for anchor handling and rig<br />

towing, with considerable equipment and<br />

materials carrying capability for rig and offshore<br />

platform supply. Vessels were carefully<br />

designed under project name NED<br />

8167 by Remontowa’s own design office,<br />

Naval Engineering & Design “NED” Ltd with<br />

special focus on draught to let both twins<br />

smoothly operate in shallow waters.<br />

Project was developed in close cooperation<br />

with Owner under “Cost Cutter” programme,<br />

what reflected not only in special<br />

attention on cutting of construction costs,<br />

but also in particular care for reduction of<br />

operation cost with keeping technical parameters<br />

on highest level possible.<br />

Propulsion is based on two stroke twin<br />

Diesel main engines delivering 2984 kW at<br />

900 rpm each to nozzled controllable pitch<br />

propellers through reduction gears. The installation<br />

provides service speed of 13<br />

knots, although maximum speed is reported<br />

to be in the region of 15 knots. Overall<br />

power plant efficiency is enhanced through<br />

the adoption of 1200 kW shaft generators.<br />

Waterfall-type, low pressure driven, towing<br />

winch consisting of two declutchable<br />

14<br />

MAIN PARTICULARS<br />

Contracted by: Remontowa S.A., Gdañsk, Poland<br />

Built at: Northern Shipyard, Gdañsk, Poland<br />

Length o.a. 67.00 m 220.00 ft<br />

Length p.p. 61.80 m 202.00 ft<br />

Breadth moulded 15.50 m 51.00 ft<br />

Depth to first deck 6.60 m 22.00 ft<br />

Design draught 4.60 m 15.00 ft<br />

Class ABS +A1, (E), Offshore Support Vessel +AMS, DPS-1, FFV Class 1<br />

Bollard pull 102.9 MT<br />

CAPACITIES<br />

Deadweight at draught of 4.60 m 1850 t<br />

Deadweight at draught of 5.10 m 2318 t<br />

Deck cargo area / load 418 m 3 / 4500 ft 3 1000 t<br />

Dry Bulk 193.6 m 3 6840 ft 3<br />

Fuel oil 873.0 m 3 5490 bbl<br />

Water Ballast / Drill Water 502.2 m 3 3158 bbl<br />

Potable Water 208.2 m 3 1309 bbl<br />

Cargo Fresh Water 766.4 m 3 4820 bbl<br />

Liquid Mud (s.g. 2.5) 470.0 m 3 3011 bbl<br />

Accommodation 28 berths<br />

towing and anchor-handling drums, each<br />

with a capacity for 1400 m of 56 m diameter<br />

wire is most vital of deck equipment instal-<br />

REMONTOWA Group<br />

TOWING SUPPLY VESSELS<br />

led onboard. The outfit includes a single<br />

storage reel to accommodate 1000 m of 64<br />

mm wire. Deck equipment consists also of<br />

September 2005

REMONTOWA Group<br />

PROPULSION / POWER SYSTEM<br />

Rated output 2 x 2984 kW (4000 HP) at 900 rpm<br />

Gearbox 2 x (200 kNm; 4.58:1)<br />

Shaft line with propeller 2 x CPP, Ø 3000 in nozzles<br />

Shaft generators 2 x 1200 kW at 1800 rpm<br />

GENERATING SETS<br />

Generating set 1 x 250 kW at 1800 rpm<br />

Emergency/harbour generator 1 x 105 kW at 1800 rpm<br />

DECK EQUIPMENT<br />

Hydraulically driven towing winch 225 t<br />

Tugger winches 2 x 10 t<br />

Stern roller 300 t / dia 1.5 m, length 2.4 m<br />

Shark jaw & towing pins 1 electro-hydraulic knuckle arm deck crane 2 t/10 m<br />

CARGO PUMPS<br />

Fuel oil 1 x 150 m 3 /h-9 bar el. dr.<br />

Fresh water 1 x 150 m 3 /h-9 bar el. dr.<br />

Ballast/Drill Water 1 x 150 m 3 /h-9 bar el. dr.<br />

Liquid Mud 2 x 150 m 3 /h-7 bar el. dr.<br />

Bulk Handling System 2 x bulk mud compressors each 1100 m 3 /h at 8 bar<br />

September 2005<br />

two tugger winches of 10 t pull each, shark<br />

jaw and towing pins. Stern roller has main<br />

dimensions of 2400 mm length and 1500<br />

mm diameter and can accommodate a 300<br />

tones design load.<br />

In addition to anchor handling and towing<br />

functions, J. Hugo Roff Jr. and Big Joe<br />

Tide are suited to rig and platform supply<br />

services by means of an open deck capacity<br />

for 1000 t of equipment and other cargo,<br />

together with tanks for drill water, potable<br />

water, liquid mud, fuel oil and dry bulks (cement,<br />

bentonite, barites etc.), located under<br />

1st deck. Moreover both vessels can be<br />

used as auxiliary fire fighters with its two<br />

1200 cubic meter fire monitors installed on<br />

superstructure.<br />

J. Hugo Roff Jr was delivered on 13 January<br />

2005. It is currently being operated off<br />

the African coasts. Big Joe Tide was delivered<br />

On 10 May 2005. Both were built at Northern<br />

Shipyard. Remontowa Shipyard has<br />

also signed next contract for another two<br />

oceangoing tugs with bollard pull of 120 t,<br />

and lenght of 70 m (see on page 50). The<br />

ships are being currently under construction<br />

with time of delivery in 2006. American partners<br />

are interested in having other ships of<br />

this kind built in Gdañsk.<br />

15

PURSE SEINER<br />

TRAWLER TEIGENES<br />

In 2004 Northern Shipyard, a subsidiary<br />

of Remontowa Group signed a contract<br />

for outfitting and delivery of Purse Seiner<br />

Trawler for Norwegian Owner – Teigenes<br />

AS from Eggesbønes.<br />

This fishing vessel (yard number B 336/<br />

1), after completion of the hull built in Romania<br />

is to be delivered in September 2005.<br />

The ship was the second purse seiner trawler<br />

contracted by Northern Shipyard after a<br />

successful of delivery of Vea fishing vessel.<br />

Technical design of the vessel is provided<br />

by Vik – Sandvik, Norway, and developed<br />

in close cooperation with Owners. New design<br />

represents state-of-the-art technology<br />

in pelagic sector, being focused on reaching<br />

most economical and effective parameters<br />

during her operation.<br />

New Teigenes is 75,40 m long with<br />

15,60 m beam and depth of 9,0 m. She is<br />

powered with hybrid propulsion system consisting<br />

of 3600 kW Diesel engine and one<br />

asychronous electrical engine of 2000 kW<br />

output. Propulsion set will drive a 3900 mm<br />

CP propeller through gearbox with PTI for<br />

electrical engine. Electric power will be supplied<br />

from two auxiliary engines of 1424 kW,<br />

one auxiliary engine of 968 kW and shaft<br />

alternator of 2770 kVA/900 rpm. Electrical<br />

driven side thrusters witf CP propeller, 1200<br />

HP located on bow and 1300 HP aft will<br />

enable effective maneuvring.<br />

16<br />

The vessel is equipped with low pressure<br />

hydraulic driven winches. Moreover,<br />

the ship is designed for installation of processing<br />

and onboard freezing equipment<br />

in future. Cargo and fishing gear will be handled<br />

by three deck cranes. Fish will be transferred<br />

into 9 RSW tanks of 2000 m3 total<br />

capacity, chilled by twin RSW system. Self<br />

discharging from all fish holds by vacuum<br />

system.<br />

Accommodation for 16 crew members<br />

in 14 single and 1 double berth cabins,<br />

messroom, saloon, galley and wardrobe has<br />

been outfitted in a high Norwegian standard.<br />

The ship was comissioned by Teigenes<br />

AS, Norwegian company founded by Mr<br />

DRAFT<br />

REMONTOWA Group<br />

Terje Teige in 1948. After having served the<br />

country during the war as a navy pilot with<br />

many missions across the North Sea, he<br />

bought his first fishing vessel in 1948. In the<br />

first years through porbeagle shark in the<br />

North Sea and along New Funland coast,<br />

and thereafter in herring, mackerel, capelin<br />

fisheries he became a well known fisherman<br />

in the region. The company Teigenes<br />

AS, which now include trawlers/pursers Teigenes<br />

and Sjobris, is now owned by his<br />

two sons, Knut and Sigurd Teige. Knut Teige<br />

is a captain of Teigenes, while Sigurd is<br />

a chairman of the company. Sigurd Teige is<br />

also well known as a chairman of The Norwegian<br />

Fishing Vessel Association.<br />

September 2005

REMONTOWA Group<br />

SHRIMP TRAWLER TRASAVIK<br />

In 2004 Northern Shipyard of Gdañsk also<br />

signed another newbuilding contract for<br />

construction and delivery of a complete<br />

Shrimp Trawler for Norwegian owner -<br />

Tråsavik ANS from Egersund. The vessel<br />

(yard number B 334/1) is to be delivered in<br />

September 2005. The vessel was a second<br />

complete fishing vessel contracted by Northern<br />

Shipyard, a member of REMONTO-<br />

WA GROUP, after successfully delivered<br />

Purse Seiner Trawler Vea.<br />

Technical design of the vessel is provided<br />

by Sawicon, naval architects from Bergen,<br />

Norway. New design represents state-of-the-art<br />

technology. Shrimp Trawler is<br />

19,80 m long with 7,50 m beam and depth<br />

of 3,80 m.<br />

Ship is powered by 800 hp main engine<br />

driving a 2000 mm CP propeller. Electric power<br />

is supplied from one auxiliary engine of<br />

85 hp output and one hydraulic driven generator<br />

with output of 45 kVA. Hydraulic driven<br />

120 hp side thruster with CP propeller, located<br />

September 2005<br />

on bow, will provide vessel’s manoeuvring.<br />

The vessel is equipped with three trawl<br />

winches and three net drums located aft.<br />

Processing equipment for catch - electric<br />

shale shaker, shrimp cooker, ice machine is<br />

located on main deck. Cargo area has been<br />

arranged with three insulated separate hold<br />

stores. Cargo will be handled using 1,5t/8m<br />

crane located on shelter deck.<br />

Accommodation for 5 crew members,<br />

galley, messroom and wardrobe is outfitted<br />

in a high Norwegian standard. Roomy wheelhouse<br />

on the vessel provides the skipper<br />

with the highest level of engine control, navigation<br />

and communication aids.<br />

Northern Shipyard, established in 1945,<br />

belongs to the Remontowa Gdañsk Shiprepair<br />

Yard Group. As its one field of specialization,<br />

the yard delivered over 150 fishing<br />

vessels of different size and type to the<br />

owners from Iceland, Norway, Faroe Islands,<br />

former Soviet Union, Poland, France<br />

and Scotland so far.<br />

To gain the shipbuilding contract, Northern<br />

Shipyard has won tough tender competition<br />

with Norwegian shipyards. The<br />

Owner appreciated the experience and<br />

high level of skilled crew, excellent and<br />

complex set of its technical facilities as well<br />

as high standard of works performed by<br />

Northern Shipyard recognized by all worldwide<br />

Classification societies and general<br />

ISO 9001:2000 certificate.<br />

DRAFT<br />

17

CRAB TRAWLER<br />

Northern Shipyard a subsidiary of<br />

Remontowa Group, completed<br />

construction of 20 m, B 335/1 vivier<br />

crabber which was delivered<br />

to the Owner, Teineskjær AS from Norway<br />

in April 2005.<br />

The vessel is another fishing vessel built<br />

at Northern Shipyard for demanding Norwegian<br />

market after successfully delivered<br />

Purse Seiner/Trawler Vea in 2004. The vessel<br />

will operate in the North Sea as first purposely<br />

designed Vivier Crabber for Norwegian<br />

Owners.<br />

The vessel is the first crab trawler ever<br />

designed and built for a Norwegian owner<br />

DRAFT<br />

18<br />

outside Norway. Technical design of the<br />

vessel is provided by Norwegian naval architects<br />

Sawicon AS, while workshop drawings<br />

are made by Yard’s subsdiary “Naval<br />

Engineering & Design”. Teineskjær represents<br />

state-of-the-art technology.<br />

New Teineskjær measures 19,99 m in<br />

length, 7,0 m in beam and 3,50 m in depth.<br />

She is powered by 441 kW Cummins<br />

KTA19 M3 main engine driving a 2000 mm<br />

CP propeller through Heimdal SG2 reduction<br />

gearbox. Vessel is equipped also with<br />

two generating sets Cummins 6CT8 3DM<br />

of 118 kW output each. Electrically driven<br />

75 kW side thrusters located fore and aft<br />

REMONTOWA Group<br />

delivered by Vestnorsk Engineering and<br />

flap rudder, provide ship with excellent manoeuvrability.<br />

The crab pots are stored in the hold below<br />

main deck. Refrigerated to -15º C bait<br />

store is cooled by Skogland unit and located<br />

next to pot store hold. Layout of the deck<br />

comprises table for emptying and rebaiting<br />

crab pots.<br />

Crab pots will be handled using 2 tons<br />

pot hauler winch located fore on the starboard<br />

side. Live crabs will be transferred to<br />

the spacious, 42 cubic meter vivier tank,<br />

outfitted with 2 seawater circulation pumps<br />

and air blowing system.<br />

Cargo will be handled using 1,1t/7m<br />

crane delivered by Norwegian Marine<br />

Equipment located on shelter deck. Access<br />

to the holds is provided by hatches<br />

on the deck as well as hydraulically operated<br />

side gate.<br />

Accommodation for 6 crew members,<br />

galley, messroom and wardrobe are outfitted<br />

in high Norwegian standard by another<br />

company within Remontowa Group, Famos.<br />

Spacious wheelhouse on the vessel provides<br />

the skipper with the highest level of<br />

engine control, navigation and communication<br />

aids.<br />

New Teineskjær will work for family<br />

enterprise established by brothers Ståle,<br />

Thorbjørn and Eivind Skoge from Skogsvåg.<br />

Shipowners not only catch crabs, but also<br />

take care of processing and retail sale.<br />

New investment will triply quantity of<br />

catch and let think young owners about future<br />

development of company.<br />

September 2005

September 2005<br />

19

The vessel is designed as a Rapid<br />

Intervention Vessel (RIV) capable<br />

of flexible operation, carrying out a Contracted<br />

wide range of attendance activities<br />

in addition to its prime task of emergency<br />

wreck intervention and wreck and obstruction<br />

location and marking.<br />

RIV is a monohull design with a hull of<br />

welded steel construction and deckhouses<br />

of welded aluminium construction. Steel hull<br />

incorporates additional strengthening in<br />

way of overside working areas.<br />

The vessel will be propelled by twin diesel<br />

engines driving twin controllable pitch<br />

propellers through reduction gearboxes.<br />

RIV will be fitted with twin high aspect ratio<br />

cantilevered rudders and a tunnel bow thruster<br />

forward to give high levels of manoeuvrability<br />

and control. The Vessel in service<br />

will be capable of operating at infinitely variable<br />

speeds varying from zero up to maximum<br />

speed. RIV is designed to achieve a<br />

trial speed of not less than 16,5 knots and is<br />

to achieve a minimum bollard pull of 25 tonnes<br />

with the main engines developing not<br />

20<br />

MAIN PARTICULARS<br />

REMONTOWA Group<br />

RAPID INTERVENTION VESSEL<br />

by: Remontowa S.A., Gdañsk, Poland<br />

Builder Northern Shipyard, Gdañsk, Poland<br />

Scheduled delivery 01.2006<br />

Length overall mld hull 39,30 m<br />

Length b.p. 34,20 m<br />

Breadth moulded 8,00 m<br />

Depth moulded to main deck 4,00 m<br />

Depth moulded to lower deck 2,70 m<br />

Depth moulded to forecastle deck 5,20 m<br />

Design draft moulded 2,40 m<br />

Draft scantling moulded 2,60 m<br />

Air draught 18,00 m<br />

The hull, machinery and electrical installations will be built and<br />

installed under special survey and in accordance with the Rules<br />

and Regulations of Lloyd’s Register of Shipping for notation:<br />

X100A1, SSC Workboat, G4, XLMC, UMS, MCM, EP, LA, DP, CM<br />

The vessel will be registered in the United Kingdom, port of registry<br />

London and will comply with the requirements of the U.K. Maritime<br />

& Coastguard Agency (MCA), the Flag Authority, for a Class VIII vessel.<br />

September 2005

REMONTOWA Group<br />

EXAMPLE<br />

more than 100% MCR. Main engines will<br />

not be rated at more than 3000kW total.<br />

Auxiliary electric power will be generated<br />

to give 400V, 50 Hz, 3 phase ,230V 1 phase<br />

and 110V 1 phase.<br />

GENERAL ARRANGEMENT<br />

September 2005<br />

The vessel will be equipped with ample<br />

and sophisticated equipment for hydrographical<br />

survey. Multi beam echo sounder, single<br />

beam echo sounder, side scan sonar,<br />

sound velocity sensors supported by most<br />

precise positioning system and post processing<br />

hardware/software enable wide range<br />

of survey activity.<br />

Thermal night vision system, motion stabilized,<br />

allows to carry out search and rescue<br />

action at any time of the day and at<br />

any weather. Any mode of sailing or position<br />

keeping can be realized both manually<br />

and automatically with using Dynamic Positioning<br />

System, which engages all components<br />

of the propulsion system - both controllable<br />

pitch propellers, both rudders and<br />

bow thruster.<br />

Fully air conditioned, high quality accommodation<br />

for a total complement of 10<br />

persons (6 + 4) will be arranged forward.<br />

The galley, messroom, changing room and<br />

galley store will be arranged in the foc’sle<br />

deckhouse. Sleeping cabins and washrooms<br />

will be arranged on the lower deck.<br />

21

In the beginning of the XVI th Century<br />

Henry VIII granted a Royal Charter to the<br />

Guild of the Holy Trinity allowing this fraternity<br />

to regulate the pilotage of the<br />

ships. Approximately one hundred years<br />

later Trinity House built its first lighthouse.<br />

This was the beginnig of the Trinity House<br />

Lighthouse Service – the organization which<br />

nowadays is the only light operator in England,<br />

Wales and the Channel Islands, as<br />

well as the pilotage authority for London and<br />

over 40 other districts.<br />

Trinity House, together with their Scotland<br />

- based sister organization – Northern<br />

Lighthouse Board, engaged Remontowa<br />

S.A. to deliver in 2006 two modern Buoy<br />

and Light Tenders to support their everyday<br />

operations. Both vessels will be designed<br />

and constructed for service as Multi Function<br />

Tenders operated throughout all seasons<br />

respectively round the coasts of Scotland<br />

and the Isle of Man by the Northern<br />

Lighthouse Board and the coasts of England,<br />

Wales and the Channel Islands by<br />

Trinity House Lighthouse Service. The vessels<br />

will be interchangeable and be capable<br />

of supporting each other’s roles.<br />

The primary functions of both vessels is<br />

to lay, retrieve and maintain navigation buoys<br />

together with their associated moorings.<br />

The vessels in addition will be designed with<br />

MAIN PARTICULARS<br />

Length overall 84,00 m<br />

Breadth moulded 16,50 m<br />

Depth moulded to main deck 7,20 m<br />

Desigh draft 4,25 m<br />

Service speed 12,50 kts<br />

CLASSIFICATION<br />

Lloyd’s Register of Shipping +100A1,<br />

UMS, CAC, DP(AA), MCM, NAV–IBS,<br />

LA EP – Buoy and Light Tender<br />

ACCOMMODATION<br />

7 officer’s cabins<br />

23 petty officer’s /crew cabins<br />

Lounge and conference area with<br />

video conferencing facilities<br />

TANK CAPACITIES<br />

Fuel oil 420 m 3<br />

Portable water 150 m 3<br />

Non portable water 140 m 3<br />

Ballast water 300 m 3<br />

22<br />

MAIN PARTICULARS<br />

BUILDER Remontowa S.A. Gdañsk, Poland<br />

SCHEDULED DELIVERY year 2006<br />

FLAG United Kingdom<br />

PORT OF REGISTRY Leith – Ship No.1<br />

London – Ship No.2<br />

REGISTERED OWNER Northern Lighthouse Board Ship No.1<br />

Trinity House Lighthouse Service Ship No.2<br />

DYNAMIC POSITIONING SYSTEM<br />

Kongsberg Simrad SDP22 system to Lloyd’s DP<br />

(AA) standard integrated navigation bridge<br />

CRANEAGE FACILITIES<br />

1 x 30 tons main crane located Port Side<br />

1 x 4 tons general purpose crane located Starboard (1,5 t at 17 mtrs)<br />

2 x 2,4 tons stores cranes<br />

HYDROGRAPHIC SURVEY INSTALLATION<br />

Kongsberg Simrad installation EA 400 single beam & EM 3002 D multi-beam units<br />

plus Kongsberg’s Neptune Triton and Poseidon software for processing the data<br />

Nautikaris tide recorder system Simrad SL 35 sonar Nautikaris Side Scan<br />

Simrad hydrographic system Seapath 2000<br />

WORKING DECK LAYOUT<br />

ATN’s: capacity for carrying of 16 navigation buoys<br />

and associated ground tackle<br />

Container carriage: 10 x 20 feet standard containers<br />

(6 of them can be refridgerated)<br />

Towing: 1 x 36 tons towing winch<br />

PROPULSION SYSTEM<br />

2 azimuth units of 1500 kW each<br />

2 bow thruster units of 750 kW each<br />

DIESEL GENERATING PLANT<br />

3 diesel engines of abt 1400 kW each<br />

2 diesel engines of abt 700 kW each<br />

1 emmergency diesel alternator of 200 kW for Ship No. 1 and 380 kW for Ship No. 2<br />

1 harbour diesel alternator of 300 kW for Ship No. 1<br />

the capability to carry out other offshore multi-function<br />

roles, including towing, hydrographic<br />

surveys, attendance at wrecks, transportation<br />

of personnel, plant and equipment<br />

to offshore stations and support safe workboat<br />

and helicopter operations.<br />

Vessels will be arranged with an open<br />

clear working deck aft, serviced by a 30 tonne<br />

S.W.L. electro-hydraulic crane and arranged<br />

for the secure stowage of Class +1,<br />

Class 1 and Class 2 buoys with a designated<br />

clear area for helicopter operations.<br />

Vessels will be capable of slow speed clo-<br />

REMONTOWA Group<br />

MULTI-FUNCTION BUOY TENDERS<br />

se quarters maneuverability for accurate<br />

station keeping up to Beaufort Force 6.<br />

Both will be fitted with Dynamic Positioning<br />

System (DP2) maintaining station ±2m<br />

for the deployment and recovery of navigation<br />

buoys and other multi-disciplinary<br />

roles.<br />

Vessels will be propelled by a multi prime<br />

mover Diesel Electric propulsion installation<br />

complete with Power Management<br />

System (PMS) driving twin fixed pitch open<br />

propeller azimuthing units arranged aft and<br />

twin fixed pitch tunnel thrusters forward.<br />

September 2005

REMONTOWA Group<br />

GENERAL ARRANGEMENT<br />

September 2005<br />

23

400 PAX SHUTTLE FERRIES<br />

Norwegian owner Moltzaus Tankrederi<br />

AS has ordered in Gdañsk two<br />

modern and luxury looking ships.<br />

NB 264/1064/1 and NB 264/1064/<br />

2 Sundbusserne are 400 Pax Shuttle ferries<br />

to be operated for the transportation of<br />

passengers between Ellsinore in Denmark<br />

and Helsinborg in Sweden with speed of<br />

14 knots. Both are to be delivered in last<br />

months of 2006.<br />

The 400 Pax Shuttle ferry will be built<br />

with modern shape of hull of welded steel<br />

construction and deckhouse of welded steel/aluminium<br />

construction. The vessel is<br />

equipped with a diesel electric propulsion<br />

system consisting of 3 generator sets 711<br />

kVA each and two azimuth thrusters aft with<br />

two electric motors with power of 600 kW<br />

DRAFT<br />

24<br />

each. There is one boiler for heating. The<br />

machinery also include emergency genset<br />

220 kW, bow thruster 300 kW, one pair of<br />

heeling tanks and one pair of fin stabilizers.<br />

The ferry will be able to carry maximum<br />

400 passengers. Space for passengers will<br />

be arranged as follows: shopping area and<br />

game arcade on shopping deck (main<br />

deck), café area with 56 seats, pub area –<br />

with 96 seats and two restaurants with 54<br />

seats each on cafeteria deck (upper deck),<br />

sun deck – with 70 seats. An area for the<br />

crew is arranged separately on the bridge<br />

deck. For communication between four<br />

decks there will be fast passenger lift. Special<br />

attention is to be taken for low level of<br />

noise and vibration. Some details of the<br />

REMONTOWA Group<br />

construction of the ship are still being developed<br />

in order to find most optimal solutions.<br />

MAIN PARTICULARS<br />

LoA app. 60,40 m<br />

LbP app. 51,20 m<br />

Breadth 11,40 m<br />

Depth (to main deck) 4,70 m<br />

Design Draught 2,80 m<br />

Passenger Capacity 400<br />

Speed 14 knots<br />

Propulsion 1200 kW<br />

Diesel – Electric<br />

Class LRS, +100A1,<br />

Ice 1C, +LMC, UMS<br />

September 2005

September 2005<br />

25

DOUBLE-ENDED FERRY SKS 86<br />

Double - ended passenger car ferry<br />

SKS-86/NB 1543 contracted by<br />

Gdañsk Shiprepair Yard REMON-<br />

TOWA SA, Poland is currently being<br />

built at Northern Shipyard. The ship has<br />

been ordered by Norwegian owner Nor-<br />

Ferjer Volda A/S, a joint venture - Stavangerske<br />

and HSD set up to serve a new route<br />

between Volda and Folkstad in Norway<br />

from 1 January 2006. The 87-metre ferry<br />

will be delivered in December 2005 and<br />

operated at Norway fiord.<br />

It can carry 300 passengers and 85 cars<br />

or 8 trucks. The ship is to be built with symmetric<br />

hull and deckhouse of welded steel<br />

construction, a continuous car deck (main<br />

deck), diesel engines powered with azimuth<br />

thrusters on each end, side house on each<br />

side with upper deck for carrying of the cars,<br />

fixed ramps for loading/unloading on each<br />

end of the side house.<br />

On side, on each end, as continuation<br />

of side house decks, it is arranged a mooring<br />

deck. The Main deck - free deck – is<br />

to be dimensioned for trailers with load of<br />

15 tons on double wheeled axles. Side<br />

house decks and ramps are to be dimensioned<br />

for holding of 1,5 ton axle load on<br />

single wheels.<br />

The ferry will be propelled by six main<br />

engines 404 kW each, driving two azimuth<br />

thruster through belts connected to shaftlines.<br />

There will be fore and aft engine rooms<br />

with three main engines in each engi-<br />

DRAFT<br />

26<br />

MAIN PARTICULARS<br />

Contracted by Gdañsk Shiprepair Yard REMONTOWA SA<br />

Builder Northern Shipyard<br />

Home port: Ålesund<br />

Length over all app. 87,60 m<br />

Length on car deck app. 84,40 m<br />

Length between PP 78,00 m<br />

Breadth moulded 16,00 m<br />

Breadth over all 16,40 m<br />

Draught DnV, CWL app. 4,50 m<br />

Draught LWL app. 3,85 m<br />

Frame spacing 0,60 m<br />

ne room. It’s designed to achieve 13 knots<br />

at 3,3 m draught.<br />

Electric power will be generated by two<br />

gensets 295 KWe (in each engine room).<br />

The vessel will be equipped with foam extingushing<br />

system for cargo hold and water<br />

mist system for engine rooms. There are<br />

two passengers lounges on the main deck.<br />

PS lounge with 48 seats and SB lounge<br />

with kiosk and 70 seats. Passengers will<br />

be able to communicate between sides via<br />

perpendicular passage in midship. Modern<br />

Koppernes MES system with three stations<br />

on the main deck is provided for evacuation<br />

passengers. ECR is to be arranged<br />

on a tank top level.<br />

The ship was launched sideways on<br />

19 th of July 2005 at Northern Shipyard.<br />

REMONTOWA Group<br />

Norwegian and Polish yards competed<br />

for the contract. The deal is a further boost<br />

for Remontowa Group, best known<br />

worldwide for its repair and conversion<br />

operations but increasingly focused on<br />

ship construction.<br />

The hull, machinery and electrical installation<br />

will be built and installed under<br />

special survey and in accordance with the<br />

Rules and Regulation of Det Norske Veritas<br />

for notation: + DNV * 1A1-R4-Class Ferry<br />

B-PWDK-E0-RP<br />

The vessel will be registered in Norway<br />

and will comply with the requirements of the<br />

Norwegian Maritime Directorate (NMD), The<br />

Flag Authority NMD TRADING AREA 2.<br />

September 2005

REMONTOWA Group<br />

ICE BREAKING EMERGENCY<br />

EVACUATION VESSELS<br />

n 22nd O<br />

of July 2005, Gdañsk Shiprepair<br />

Yard Remontowa S.A.<br />

and Agip KCO signed a contract<br />

for the construction and delivery<br />

of four specialised Ice Breaking Emergency<br />

Evacuation Vessels (IBEEV), becoming<br />

yard numbers B 843/1-4. Moreover, the contract<br />

provides the Owner’s with an option to<br />

order two additional sistervessels, to be<br />

confirmed within October this year.<br />

The vessels will be used to carry out the<br />

emergency evacuation of personnel from<br />

offshore installations located in the Kashagan<br />

Field, which is currently one of the largest<br />

offshore developments in the world<br />

(and which forms part of the Kazakhstan<br />

Economical zone).<br />

Technical design and workshop drawings<br />

of the vessel will be provided by the<br />

Yard’s subsidiary Naval Engineering & Design<br />

Ltd. and based on the Owner’s basic<br />

concept design.<br />

IBEEV represents state-of-the-art technology<br />

and will comply to DNV notation X<br />

1A1 ICE 1B DAT (-30° C).<br />

IBEEV measures 45,10 m in length, 8,0<br />

m in beam and 3,60 m in depth. The specific<br />

requirements of Agip KCO as well as the<br />

onerous environmental operating conditions<br />

have challenged the Yard to develop<br />

tailor made solutions for this project.<br />

DRAFT<br />

September 2005<br />

Special focus has been put on the development<br />

of the propulsion solution, allowing<br />

the vessels to operate safely within a<br />

toxic/hydrocarbon environment. Combustion<br />

air will be provided by a specialized installation<br />

consisting of 16 high pressure cylinders<br />

storing air compressed to 350 bar, decompressed<br />

via pressure reducing panels<br />

and supplied to the engines. IBEEV will<br />

have diesel electric propulsion, consisting<br />

of two 800kW diesel-electric prime movers<br />

running at 1500 rpm and driving twin azimuth<br />

thrusters rated at 550 kW at 1500 rpm.<br />

The winter ice conditions prevailing in<br />

the North East Caspian resulted in the designers<br />

developing a hull form with the capability<br />

for vessel operation in «first year» ice<br />

(0.6 m thick), which was proved by extensive<br />

model tests. The shallow waters of Caspian<br />

Sea also required tight design control<br />

over draught of the vessel, which is not<br />

to exceed 2,0 m in summer and 2,1 in winter<br />

conditions. Environmental factors were<br />

also taken into account, resulting in the application<br />

of “no discharge” equipment and<br />

fulfilment of requirements of MARPOL as<br />

well as other International Conventions.<br />

IBEEV has been designed to evacuate<br />

340 persons at a time. Evacuees will enter<br />

the vessels through evacuation tunnels linking<br />

each vessel to the Kashagan ‘D’-Is-<br />

land facility. Evacuees will enter the vessel<br />

via an air lock which will be purged using<br />

stored air from cylinders, afterwards the evacuees<br />

will proceed forward through the vessel,<br />

to one of three hermetically sealed evacuee<br />

compartments. During evacuation,<br />

personal CO 2 scrubbers and re-breather<br />

sets will be provided to each of the evacuees.<br />

Solid-state chlorate candles will be<br />

used to generate additional oxygen in the<br />

evacuee compartments as the oxygen levels<br />

are depleted by the evacuees.<br />

Delivery of contracted vessels is scheduled<br />

for September 2006.<br />

For more information,<br />

please contact:<br />

“Remontowa” S.A.<br />

Na Ostrowiu 1 , 80-958 Gdañsk<br />

Poland<br />

Mr. Miroslaw Jasinski<br />

Deputy Director<br />

of Commerce & Offshore<br />

Miroslaw.Jasinski@remontowa.com.pl<br />

Tel. +48 58 307 23 10<br />

Fax. +48 58 307 23 20<br />

27

ANCHOR HANDLING<br />

J<br />

The first half of 2005 became fruitful<br />

for the Offshore Department of<br />

Remontowa when Tidewater Marine<br />

LLC decided to continue cooperation<br />

in newbuilding with Gdañsk Shiprepair Yard<br />

“Remontowa” S.A. Tidewater Marine, based<br />

in New Orleans, USA, placed an order<br />

for a pair of type NED 8167 L anchor handling<br />

towing supply vessels (AHTSV) with<br />

options for two more ships.<br />

The new vessels will be based on a project,<br />

NED 8167, that has already been completed<br />

for the same Owner. These vessels<br />

have been improved for this new endeavor<br />

through the base of experience gained during<br />

the construction of the previously delivered<br />

pair, the “J HUGH ROFF JR” and the<br />

“BIG JOE TIDE” Both of those vessels were<br />

delivered earlier this year by Remontowa.<br />

The main change of the earlier design<br />

is reflected in the length of the vessel. The<br />

new revision has a length of 70.0 m, but the<br />

breadth and depth remain as 15.50 m and<br />

6.60 m, respectively. Just as for the previous<br />

vessels, the recently contracted NED<br />

8167 L pair is designed to operate in shallow<br />

waters. Due to a limited rearrangement<br />

of the aft part of the ship, the continuous<br />

bollard pull will be increased to 120 tonnes<br />

with a simultaneous increase of the vessels’<br />

28<br />

TOWING VESSEL NED 8167 L<br />

MAIN PARTICULARS<br />

Length o.a. 70.00 m 230.00 ft<br />

Length b.p. 66.60 m 218.50 ft<br />

Breadth moulded 15.50 m 51.00 ft<br />

Depth to 1st Deck 6.60 m 22.00 ft<br />

Design draught 5.10 m 16.73 ft<br />

Class ABS +A1 (E), Offshore Support Vessel,<br />

+AMS,+DPS-1,+FFV Class 1<br />

Bollard pull 120 MT<br />

CAPACITIES<br />

Deadweight at draught of 5.10 m 2050 t<br />

Deck cargo area / load 437.0 m² 4704 ft²/1000 t<br />

Dry Bulk 193.6 m³ 6840 ft³<br />

Fuel oil 730.0 m³ 5490 bbl<br />

Water Ballast / Drill Water 885.0 m³ 5566 bbl<br />

Potable Water 100.0 m³ 628 bbl<br />

Cargo Fresh Water 535.0 m³ 3364 bbl<br />

Liquid Mud (s.g. 2.5) 485.0 m³ 3050 bbl<br />

Accommodation 28+1 berths<br />

PROPULSION / POWER SYSTEM<br />

REMONTOWA Group<br />

Rated output 2 x 3730 kW (5000 HP) at 900 rpm<br />

Gearbox 2 x (165 rpm; 5.45:1)<br />

Shaft line with propeller 2 x CPP, Ø 3400 in nozzles<br />

Shaft generators 2 x 1200 kW at 1800 rpm<br />

September 2005

REMONTOWA Group<br />

DECK EQUIPMENT<br />

Hydraulically driven towing winch 300 t<br />

Tugger winches 2 x 10 t<br />

Stern roller 400 t / dia 2.0 m, length 4.0 m<br />

Shark jaws & towing pins 1 set<br />

Deck crane 1 electro-hydraulic knuckle arm 2 t/10 m<br />

capacities, meanwhile keeping other vital<br />

features of the ship operating at the highest<br />

possible level.<br />

The recently contracted AHTSV’s are<br />

modern multipurpose vessels designed for<br />

anchor handling and rig towing with significant<br />

cargo capability for rig and offshore<br />

platform supply. As was the case with previous<br />

ships for Tidewater, Remontowa is<br />

using the same design office, Remontowa’s<br />

own Naval Engineering & Design Ltd. NED.<br />

Propulsion is based on American two stroke<br />

twin Diesel main engines. Each of the two<br />

engines deliver 5000 BHP at 900 rpm through<br />

reduction gears to controllable pitch propellers<br />

located inside Kort Nozzles. The machinery<br />

is designed to provide a service speed<br />

of 13 knots, and a maximum speed to exceed<br />

15 knots. The overall power plant efficiency<br />

will be improved through the adoption<br />

of 1200 kW shaft generators. New vessels<br />

are to be classed as DP-1, but shall be<br />

GENERAL ARRANGEMENT<br />

September 2005<br />

ready for upgrading to DP-2 if so required by<br />

a potential client. In order to ensure that the<br />

vessel is ready for this upgrade, two 800 HP<br />

side thrusters shall be installed along with<br />

two 250 kW auxiliary generator sets.<br />

A waterfall-type towing winch with 300<br />