Mechanical Design of the LMDE.pdf - Heroicrelics

Mechanical Design of the LMDE.pdf - Heroicrelics

Mechanical Design of the LMDE.pdf - Heroicrelics

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

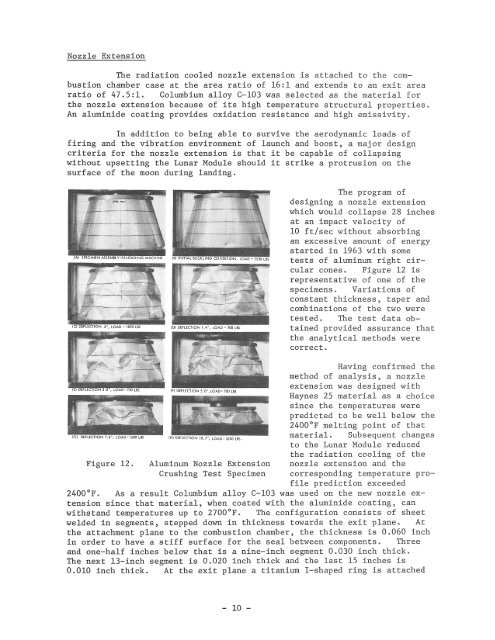

Nozzle ExtensionThe radiation cooled nozzle extension is attached to <strong>the</strong> combustionchamber case at <strong>the</strong> area ratio <strong>of</strong> 16:1 and extends to an exit arearatio <strong>of</strong> 47.5:1. Columbium alloy C-l03 was selected as <strong>the</strong> material for<strong>the</strong> nozzle extension because <strong>of</strong> its high temperature structural properties .An aluminide coating provides oxidation resistance and high emissivity .In addition to being able to survive <strong>the</strong> aerodynamic loads <strong>of</strong>firing and <strong>the</strong> vibration environment <strong>of</strong> launch and boost, a major designcriteria for <strong>the</strong> nozzle extension is that it be capable <strong>of</strong> collapsingwithout upsetting <strong>the</strong> Lunar Module should it strike a protrusion on <strong>the</strong>surface <strong>of</strong> <strong>the</strong> moon during landing.Figure 12.Aluminum Nozzle ExtensionCrushing Test SpecimenThe program <strong>of</strong>designing a nozzle extensionwhich would collapse 28 inchesat an impact velocity <strong>of</strong>10 ft/sec without absorbingan excessive amount <strong>of</strong> energystarted in 1963 with sometests <strong>of</strong> aluminum right circularcones . Figure 12 isrepresentative <strong>of</strong> one <strong>of</strong> <strong>the</strong>specimens . Variations <strong>of</strong>constant thickness, taper andcombinations <strong>of</strong> <strong>the</strong> two weretested. The test data ob tained provided assurance that<strong>the</strong> analytical methods werecorrect.Having confirmed <strong>the</strong>method <strong>of</strong> analysis, a nozzleextension was designed withHaynes 25 material as a choicesince <strong>the</strong> temperatures werepredicted to be well below <strong>the</strong>2400°F melting point <strong>of</strong> thatmaterial . Subsequent changesto <strong>the</strong> Lunar Module reduced<strong>the</strong> radiation cooling <strong>of</strong> <strong>the</strong>nozzle extension and <strong>the</strong>corresponding temperature pr<strong>of</strong>ileprediction exceeded2400°F. As a result Columbium alloy C-l03 was used on <strong>the</strong> new nozzle extensionsince that material, when coated with <strong>the</strong> aluminide coating, canwithstand temperatures up to 2700°F. The configuration consists <strong>of</strong> sheetwelded in segments, stepped down in thickness towards <strong>the</strong> exit plane. At<strong>the</strong> attachment plane to <strong>the</strong> combustion chamber, <strong>the</strong> thickness is 0 . 060 inchin order to have a stiff surface for <strong>the</strong> seal between components . Threeand one-half inches below that is a nine-inch segment 0.030 inch thick .The next l3-inch segment is 0.020 inch thick and <strong>the</strong> last 15 inches is0.010 inch thick. At <strong>the</strong> exit plane a titanium I-shaped ring is attached- 10 -