the power - Global Media Publishing Ltd. - UK.COM

the power - Global Media Publishing Ltd. - UK.COM

the power - Global Media Publishing Ltd. - UK.COM

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

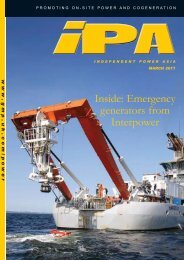

GEN-SETGen-sets to <strong>the</strong> rescue:DEIF’s role in post-tsunami JapanMost people remember Japan’s devastating March 2011 earthquake and tsunami, but few knowthat it was DEIF Power & Control Technology which delivered a sophisticated AGC PlantManagement system for <strong>the</strong> vast emergency grid set up to supply <strong>the</strong> Hitachinaka area.Following <strong>the</strong> critical failure andradiation leaks at <strong>the</strong> Fukushima INuclear Power Plant, <strong>the</strong>Hitachinaka area of Fukushima region wasleft without regular <strong>power</strong> supplies.Japan’s government turned to <strong>the</strong> DEIFGroup’s engineers and developers toprovide a ground-breaking PlantManagement <strong>power</strong> solution in a formatnever seen before, as fast as possible.The DEIF solution involved providing 64gen-sets producing 130MW; <strong>the</strong> plant isable to supply an average of 300,000households annually.According to DEIF, ‘<strong>the</strong> beauty of AGCPlant Management lies in <strong>the</strong> simplicity ofits basic principle, lifting genset controlfrom single units to plant level, enablingadvanced control and protection for largesetups from one central point ofintelligence.’AGC Plant Management incorporatesplant <strong>power</strong> factor control at connectionpoints, scaling, load profile prioritiesroutines, and uses fan control to reducefuel costs.The system uses <strong>the</strong> plant’s generatorsto black start large step-up transformerswith <strong>the</strong> push of a button. The solutionhas a proven ratio of up to 1:27 between<strong>the</strong> generator and <strong>the</strong> transformer, costoptimisingblack starts in both island andfixed <strong>power</strong> mode by limiting <strong>the</strong> need forhigh voltage breakers.With a dedicated plant communicationstructure, SCADA systems are keptseparate from <strong>the</strong> control system. As aresult, <strong>the</strong> system’s performance is notcompromised and on-site installation canbe reduced to a minimum, says DEIF.When operating in fixed <strong>power</strong> mode,<strong>the</strong> AGC Plant Management system assignsgenerators <strong>the</strong>ir most fuel-efficient <strong>power</strong>setpoint. If a generator trips or fails todeliver <strong>the</strong> required amount of <strong>power</strong>, <strong>the</strong>o<strong>the</strong>r generators automatically departfrom <strong>the</strong>ir optimum setpoints to fill <strong>the</strong>production dip untila new generatorstarts up. With <strong>the</strong>new generator properlysynchronised,<strong>the</strong> generatorsreturn to <strong>the</strong>ir originalfuel-optimisedsetpoint.Today, <strong>the</strong> PlantManagement systemat Hitachinaka canhandle up to 16 gridconnection points,eight bus tie breakers and 256 generatorbreakers. Developed not just with an eyefor safety but for fuel-saving andoptimised maintenance intervals as well,<strong>the</strong> strategy for a set of 64 generators,for instance, could reduce fuelconsumption by as much as 18,000 litresof diesel a day on a continuous use basis.The above features are standard in <strong>the</strong>DEIF AGC Plant Management Controllerwhich was released commercially in late2011, following more than three years ofintensive research and testing at sitesacross South America, Africa, and Asia.For some years now, DEIF has beenresponding to a growing market demandfor temporary and emergency plants toprovide support for remote locations withlimited access to distribution, disasterrelief and o<strong>the</strong>r unscheduled outages aswell as large industrial facilities.DEIF’s aim has been to optimise <strong>power</strong>management for <strong>the</strong>se types of setups.DEIF’s guiding principle is to explorenew approaches to <strong>power</strong> control andcreate innovative, cost-effective, andCO2-friendly solutions, reports <strong>the</strong>company.WIPInternet linkwww.deif.com40M ARCH 2012 • WORLDWIDE I NDEPENDENT P OWER