Cameron API 6A Gate Valves - cedip

Cameron API 6A Gate Valves - cedip

Cameron API 6A Gate Valves - cedip

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

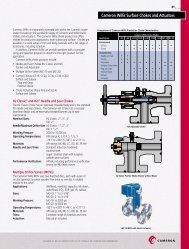

FLS-R <strong>Gate</strong> ValveThe <strong>Cameron</strong> FLS-R <strong>Gate</strong> Valve wasdesigned for use as a manual valve in highpressure,large bore applications. This valveincorporates a lower balancing stem and unique ballscrew mechanism for ease of operation in the field.The FLS-R is value-engineered for reliability, lowtorque, ease of operation and service. The FLS-R has many of thesamefeatures as the FLS including the gate and seat design.Features and Benefits¥ Bi-directional design provides flow direction versatilityand increased service life.¥ Positive metal-to-metal sealing (gate-to-seat and seat-to-body).¥ Simple, reliable gate and seat design promotes ease of field serviceand minimal spare parts inventory.¥ Two spring-loaded, pressure energized, non-elastomeric lip-sealsbetween each seat and body assist in low pressure sealing. Theyalso protect against intrusion of particle contaminants into thebody cavity and seal areas.¥ Lower stem balances pressure thrust on upper stem to reduceoperating torque, prevents body cavity pressure build-upduring operation, and provides position indication.¥ Spring-loaded, pressure energized, non-elastomericstem seal covers full range of pressures,temperatures, and fluids.¥ Pressure-energized metal-to-metal bonnet seal.¥ Either stem can be backseated to allow stemseal replacement with valve under pressure.¥ Grease injection fittings located on thedownstream side of the stem and thebalancing stem backseat for safety.FLS-R Seal<strong>Cameron</strong> FLS-R <strong>Gate</strong> <strong>Valves</strong> incorporatedual spring-loaded lip seals as shownin this detail.8

3.75"EFFLS-R Operating and Dimensional Data(inches and pounds)Nominal Working Dimensions (in.)NumberSize Pressure Weight of(in.) (psi)A B C D E F G(lbs) Turns4-1/16 15,000 29.00 15.90 39.70 11.60 41.70 24.00 24.40 1550 195-1/8 10,000 29.00 15.90 40.40 12.60 42.40 24.00 26.60 1565 23.215,000 35.00 17.80 40.50 15.00 42.50 34.00 24.20 2980 24DG6-3/8 10,000 35.00 17.40 45.70 14.60 47.70 34.00 30.00 2500 28.815,000 41.00 24.00 58.90 12.00 60.90 40.00 34.10 6780 15.47-1/16 10,000 35.00 18.90 47.70 18.10 49.70 34.00 29.00 3900 319 5000 41.00 23.00 53.20 9.75 55.20 24.00 33.70 4550 38.3AAdditional sizes and working pressures are available. Contact your <strong>Cameron</strong> representative.FLS-R <strong>Gate</strong> Valve - Side ViewCFLS-R Operating and Dimensional Data(millimeters and kilograms)Nominal Working Dimensions (mm)NumberSize Pressure Weight of(in.) (psi)A B C D E F G(kg) Turns4-1/16 15,000 736.60 403.86 1008.38 294.64 1059.18 609.60 619.76 703.07 195-1/8 10,000 736.60 403.86 1026.16 320.04 1076.96 609.60 675.64 709.87 23.215,000 889.00 452.12 1028.70 381.00 1079.50 863.60 614.68 1351.70 246-3/8 10,000 889.00 441.96 1160.78 370.84 1211.58 863.60 762.00 1133.98 28.815,000 1041.40 609.60 1496.06 304.80 1546.86 1016.00 866.14 3075.35 15.47-1/16 10,000 889.00 480.06 1211.58 459.74 1262.38 863.60 736.60 1769.00 31B9 5,000 1041.40 584.20 1351.28 247.65 1402.08 609.60 855.98 2063.84 38.3Additional sizes and working pressures are available. Contact your <strong>Cameron</strong> representative.FLS-R <strong>Gate</strong> Valve - End ViewFLS-R Valve Trim Chart<strong>API</strong> <strong>6A</strong> Classification Body and Stem <strong>Gate</strong> SeatBonnet Material Material/Coating Material/CoatingMaterial/CoatingAA - General Service Alloy Alloy 718 Alloy steel Alloy steelsteel nitrided nitridedTorque ComparisonTorque*Typical Values **Actual Test DataConventionalFLS-R(Non-Rising Stem)Design**Design*Direct to 6:1 TorqueStem Multiplier39 Turns 234 Turns 31 TurnsOpening Torque 1500 ft-lbf 313 ft-lbf 150 ft-lb(avg.)(10,000 psi differential) 2035 Nm 425 Nm 20Nm(first 3.25 turns) (first 19.5 turns) (first 3 turns)Opening Torque 55 ft-lbf 11.5 ft-lbf 15 ft-lb(avg.)BB - General Service Alloy steel Alloy 718 AISI 410 nitrided Solid cobaltalloyor chrome-plated or 410, cobaltalloy hard-facedCC - General Service 12 Cr SS Alloy 718 AISI 410 nitrided Solid cobaltalloyor chrome-plated or 410, cobaltalloy hard-facedDD - Sour Service * Alloy steel Alloy 718 Alloy steel Solid cobaltalloyhard-faced or 410, cobaltalloy hard-facedEE - Sour Service* Alloy steel Alloy 718 AISI 410 SS Solid cobaltalloyhard-faced or 410, cobaltalloy hard-facedFF - Sour Service * 12 Cr SS Alloy 718 AISI 410 SS Solid cobalt* as defined by NACE Standard MR 0175Note: Specifications are subject to change without notice. Special trims are available upon request.9

M <strong>Gate</strong> <strong>Valves</strong>The <strong>Cameron</strong> M <strong>Gate</strong> Valve, with expandingPow-R-Seal gate design, non-rising stem, andmetal-to-metal sealing provides safe, dependableservice in applications of 2000 to 5000 psiWP. It is available in sizes from 2-1/16Óthrough 4-1/16Ó with either threaded orflanged ends. The M valve is available in trims for alltypes of oilfield service, including extreme sour gas.Features and Benefits¥ Metal-to-metal sealing (gate-to-seat and seat-to-body).¥ Expanding gate design creates a positive mechanical sealacross the seats, with or without line pressure.¥ Full-bore, through-conduit gate-to-seat seal maximizesvalve life by virtually eliminating turbulence andpressure drop.¥ <strong>Gate</strong> skirts reduce loss of body lubricants.¥ Low running stress enhances life of the gate-to-seatinterface.¥ Upper/lower roller thrust bearings are isolatedfrom well fluid, minimizing torque.¥ Stem packing can be re-energized with valveunder pressure.¥ Non-rising stem permits valve installation incloser quarters.¥ Seats, gates, stem, and other working parts arefield replaceable.10

M215 <strong>Gate</strong> ValveThe <strong>Cameron</strong> M215 <strong>Gate</strong> Valve, with expandingPow-R-Seal gate design, pressurebalanced stem, andmetal-to-metalsealing provides safe,dependable service in10,000 psi WP applications. It is available in sizesfrom 1-13/16Ó through 3-1/16Ó with flanged ends. TheM215 is available in trims for all types of oilfield service,including extremesour gas.Features and Benefits¥ Pressure balancing lower stem reduces load on the bearingsand stem threads, resulting in lower operating torque.¥ Metal-to-metal sealing (gate-to-seat and seat-to-body).¥ Stem threads are outside the valve body, removed fromwellbore fluids.¥ Expanding gates create a positive mechanical seal acrossthe seats, with or without line pressure.¥ Positive mechanical seal of gatesisolates bodycavity from wellbore pressure,permitting pressure venting,whether valve is open or closed.¥ Full-bore, through-conduitdesign virtually eliminatesturbulence and pressure drop.¥ Seats, gates, stem and otherworking parts are fieldreplaceable.¥ Injectable stem packing can bere-energized while the valve is under12

FM215 Operating and Dimensional Data(inches and pounds)4.25”ENominal Working Dimensions (in.) FlangedNumberSize Pressure Weight of(in.) (psi)A B C D E F(lbs) Turns(Flgd)1-13/16 10,000 18.25 7.50 21.00 14.31 17.50 14.00 275 142-1/16 10,000 20.50 8.50 21.81 16.88 19.00 18.00 545 122-9/16 10,000 22.25 9.50 23.50 17.75 21.00 20.00 565 15DAM215 <strong>Gate</strong> Valve - Side ViewM215 Operating and Dimensional DataNominal Working Dimensions (mm) FlangedNumberSize Pressure Weight of(in.) (psi)A B C D E F(kg) Turns(Flgd)1-13/16 10,000 463.55 190.50 533.40 363.47 444.50 355.60 124.74 142-1/16 10,000 520.70 215.90 553.97 428.75 482.60 457.20 247.21 122-9/16 10,000 565.15 241.30 596.90 450.85 533.40 508.00 256.28 15BM215 Valve Trim Chart<strong>API</strong> <strong>6A</strong> Body and Stem <strong>Gate</strong> SeatClassification Bonnet Material/ Material/ Material/Material Coating Coating CoatingBM215 <strong>Gate</strong> Valve - End ViewAA - General Service Alloy Alloy Alloy Alloysteel steel steel steelBB - General Service Alloy 17-4PH SS 410 SS 410 SSsteel nitrided nitridedCC - General Service 12 Cr SS 17-4PH SS 410 SS 410 SSnitridednitridedDD - Sour Service * Alloy 17-4PH SS Alloy steel Alloy steelsteel nitrided nitridedEE - Sour Service* Alloy 17-4PH SS 410 SS 410 SSsteel nitrided nitridedFF - Sour Service * 12 Cr SS 17-4PH SS 410 SS 410 SScobalt alloy cobalt alloy* as defined by NACE Standard MR 0175Note: Specifications are subject to change without notice. Special trims are available upon request.13

Western Hemisphere<strong>Cameron</strong>PO Box 1212Houston Texas 77251-1212Tel 713 939 2211Fax 713 939 2620http://www.camerondiv.comEastern HemisphereCooper <strong>Cameron</strong> (U.K.) Ltd.205 Holland Park AvenueLondon, WII 4XBEnglandTel 44 171 6020888Fax 44 171 6027228http://www.camerondiv.comAsia Pacific/Middle EastCooper <strong>Cameron</strong> (Singapore) Pte. Ltd.No. 2 Gul Circle, Jurong Industrial EstLocked Bag Service No. 3Jurong Town Post OfficeSingapore 2262Republic Of SingaporeTel 65 8613355Fax 65 8616197http://www.camerondiv.com© Cooper <strong>Cameron</strong> Corporation, <strong>Cameron</strong> Division, Printed in USA, 3/99, TG/5M, WR10028/TC1201