CIMCO CNC-Calc 2 Tutorial

CIMCO CNC-Calc 2 Tutorial

CIMCO CNC-Calc 2 Tutorial

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

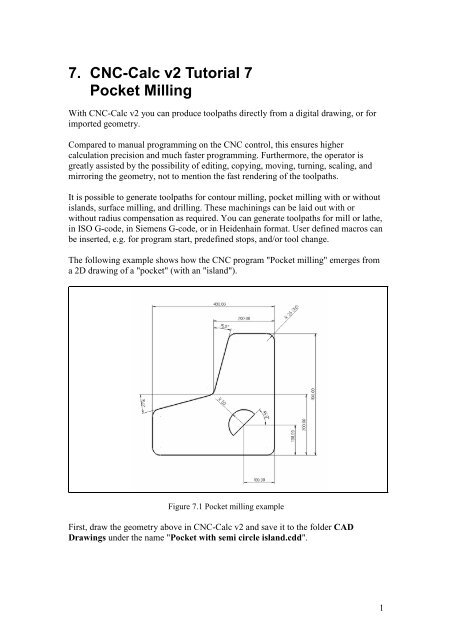

7. <strong>CNC</strong>-<strong>Calc</strong> v2 <strong>Tutorial</strong> 7Pocket MillingWith <strong>CNC</strong>-<strong>Calc</strong> v2 you can produce toolpaths directly from a digital drawing, or forimported geometry.Compared to manual programming on the <strong>CNC</strong> control, this ensures highercalculation precision and much faster programming. Furthermore, the operator isgreatly assisted by the possibility of editing, copying, moving, turning, scaling, andmirroring the geometry, not to mention the fast rendering of the toolpaths.It is possible to generate toolpaths for contour milling, pocket milling with or withoutislands, surface milling, and drilling. These machinings can be laid out with orwithout radius compensation as required. You can generate toolpaths for mill or lathe,in ISO G-code, in Siemens G-code, or in Heidenhain format. User defined macros canbe inserted, e.g. for program start, predefined stops, and/or tool change.The following example shows how the <strong>CNC</strong> program "Pocket milling" emerges froma 2D drawing of a "pocket" (with an "island").Figure 7.1 Pocket milling exampleFirst, draw the geometry above in <strong>CNC</strong>-<strong>Calc</strong> v2 and save it to the folder CADDrawings under the name "Pocket with semi circle island.cdd".1