May/June 2010 - O Scale Trains Magazine Online

May/June 2010 - O Scale Trains Magazine Online

May/June 2010 - O Scale Trains Magazine Online

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

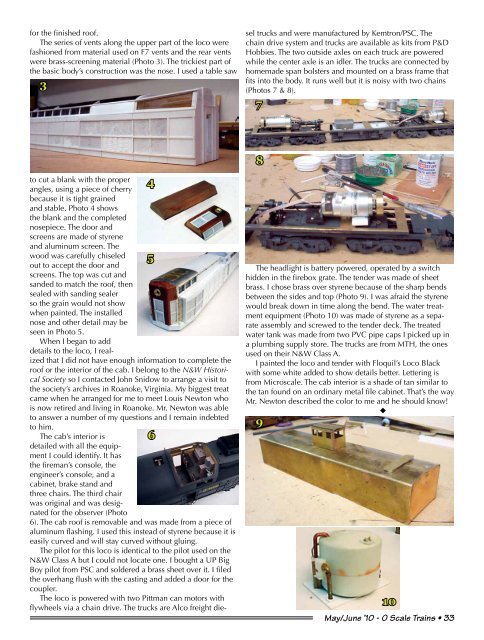

for the finished roof.The series of vents along the upper part of the loco werefashioned from material used on F7 vents and the rear ventswere brass-screening material (Photo 3). The trickiest part ofthe basic body’s construction was the nose. I used a table saw36). The cab roof is removable and was made from a piece ofaluminum flashing. I used this instead of styrene because it iseasily curved and will stay curved without gluing.The pilot for this loco is identical to the pilot used on theN&W Class A but I could not locate one. I bought a UP BigBoy pilot from PSC and soldered a brass sheet over it. I filedthe overhang flush with the casting and added a door for thecoupler.The loco is powered with two Pittman can motors withflywheels via a chain drive. The trucks are Alco freight dieseltrucks and were manufactured by Kemtron/PSC. Thechain drive system and trucks are available as kits from P&DHobbies. The two outside axles on each truck are poweredwhile the center axle is an idler. The trucks are connected byhomemade span bolsters and mounted on a brass frame thatfits into the body. It runs well but it is noisy with two chains(Photos 7 & 8).78to cut a blank with the properangles, using a piece of cherrybecause it is tight grainedand stable. Photo 4 showsthe blank and the completednosepiece. The door andscreens are made of styreneand aluminum screen. Thewood was carefully chiseledout to accept the door andscreens. The top was cut andsanded to match the roof, thensealed with sanding sealerso the grain would not showwhen painted. The installednose and other detail may beseen in Photo 5.When I began to adddetails to the loco, I realizedthat I did not have enough information to complete theroof or the interior of the cab. I belong to the N&W HistoricalSociety so I contacted John Snidow to arrange a visit tothe society’s archives in Roanoke, Virginia. My biggest treatcame when he arranged for me to meet Louis Newton whois now retired and living in Roanoke. Mr. Newton was ableto answer a number of my questions and I remain indebtedto him.The cab’s interior isdetailed with all the equipmentI could identify. It hasthe fireman’s console, theengineer’s console, and acabinet, brake stand andthree chairs. The third chairwas original and was designatedfor the observer (Photo456The headlight is battery powered, operated by a switchhidden in the firebox grate. The tender was made of sheetbrass. I chose brass over styrene because of the sharp bendsbetween the sides and top (Photo 9). I was afraid the styrenewould break down in time along the bend. The water treatmentequipment (Photo 10) was made of styrene as a separateassembly and screwed to the tender deck. The treatedwater tank was made from two PVC pipe caps I picked up ina plumbing supply store. The trucks are from MTH, the onesused on their N&W Class A.I painted the loco and tender with Floquil’s Loco Blackwith some white added to show details better. Lettering isfrom Microscale. The cab interior is a shade of tan similar tothe tan found on an ordinary metal file cabinet. That’s the wayMr. Newton described the color to me and he should know!u910<strong>May</strong>/<strong>June</strong> ’10 - O <strong>Scale</strong> <strong>Trains</strong> • 33