TC1395 Lg B Gate Vlv Bro 2001 - cedip

TC1395 Lg B Gate Vlv Bro 2001 - cedip

TC1395 Lg B Gate Vlv Bro 2001 - cedip

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

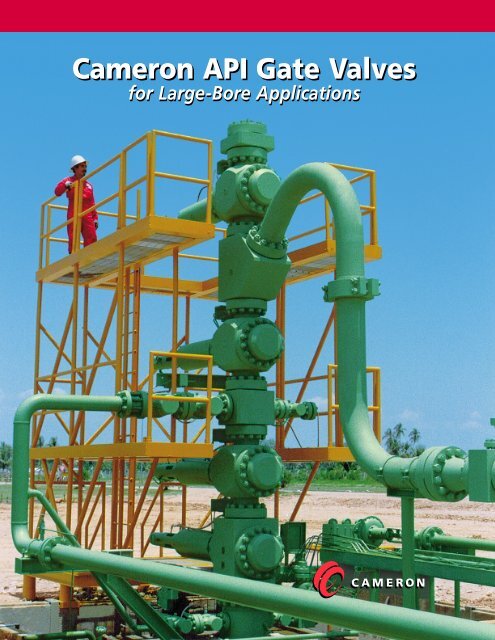

Cameron API <strong>Gate</strong> Valvesfor Large-Bore Applications

Cameron API <strong>Gate</strong> Valves for Large-Bore ApplicationsTo enable operators to optimize production rates andachieve quicker return on their investment from largereservoirs, Cameron has developed and supplied a varietyof large-bore API 6A gate valve designs.Cameron’s experience withlarge-bore gate valves began in theearly 1970s with the development of arange of valves including 6-3/8”10,000 psi WP and 9” 5000 psi WPdesigns. These valves were similar tothe highly successful Cameron FLSgate valve design. The FLS designwas ideal because of its slab gate andproven dependability in a wide varietyof surface and subsea drilling andproduction applications, includingsandy service.These early large-bore valves weremanually actuated and used torquemultipliers to reduce the operationaltorque. However, as pressures andbore sizes increased, so did torque.This led to the use of hydraulic actuationto overcome the high torquerequirements.Building on the success of the FLSgate valve in the 1990s, Camerondeveloped the FLS-R manual gatevalve. This valve incorporates manyof the features of the FLS and isdesigned specifically to meet thedemands of the large-bore marketwith low torque operation.Cameron is the industry leader in the design, manufactureand installation of large-bore gate valves for subsea andsurface applications. Cameron FLS and FLS-R gate valveshave proven themselves time after time in demandingapplications from deepwater subsea manifolds in the Gulfof Mexico, to harsh environments in the North Sea anddemanding fraccing service in South Texas.Cameron offers a family of valves to meet the needs ofthe large-bore market. For actuated surface applications,the Cameron FLS valve is paired with a Cameron WillisSaf-T-Gard hydraulic actuator. For manual surface applications,the FLS-R gate valve offers low-torque opening andclosing. For subsea applications, the FLS-R valve is pairedwith a Cameron Compact Modular (CM) actuator or a doubleacting hydraulic actuator with manual ROV back-up.Both the FLS and the FLS-R gate valves offer the samefield-proven features. Both are designed to API 6A and 17Dspecifications and are slab gate, full bore, through conduitvalves. They offer full bore operation,unlike reduced bore API 6D designs.These valves are available in all API 6Amaterial classes and temperature classes.Weld-cladding of bodies and bonnetswith CRA alloy 625 is available in metalseal areas or on all wetted surfaces.5” x 2” 10,000 psi WP SpoolTree Production Systemwith FLS <strong>Gate</strong> Valves and CM Actuators Valves andCM Actuators11" 5000 psi WP FLS-R valve onsubsea manifold7-1/16" 10,000 psi WP large-borevalve in fraccing applicationFLS & FLS-R <strong>Gate</strong> Valve Sizes Currently AvailableNominalWorking Pressure (psi)Size 5000 10,000 15,0005-1/8” 3 3 36-3/8” 3 3 37-1/16” 3 3 39” 3 3 —11” 3 — —COVER: 9" 5000 psi WP Christmastree with FLS gate valves9" 10,000 psi WP FLS valves on subsea manifoldOther sizes and pressure ratings are available upon request.1

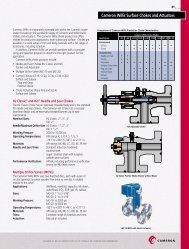

FLS <strong>Gate</strong> Valves with Hydraulic ActuatorManual FLS-R <strong>Gate</strong> ValveThe Cameron large-bore valve designs are the model FLS andmodel FLS-R. The superior performance of these valves has beenproven in extensive testing, in production service, in drillingservice, and in special operations such as fraccing service.Common features of the FLS and FLS-R valve designs include:• Bi-directional design provides flow direction versatility andincreased service life.• Simple, reliable slab gate and one-piece seat design promotesease of field service.• A patented seat design with two spring-loaded, pressureenergized, non-elastomeric lip seals is installed between eachseat and the body. The seals isolate metal-to-metal sealsurfaces from contaminants and preload the seats to effectlow-pressure sealing.• A spring-loaded, non-elastomeric stem seal covers the fullrange of pressures, temperatures, and fluids. Cameron stemseals have been fully qualified by API 6A Appendix F testing.• A pressure-energized, metal-to-metal bonnet seal ensuresexternal seal integrity.For surface safety-valve applications, the FLS valves areequipped with Cameron Willis Saf-T-Gard hydraulic actuators.These compact, modular actuators are available in either wirecuttingor non wire-cutting versions. Accessories such as visualand electric position indicators are available for the actuators.The FLS is also offered witha double-acting hydraulicactuator, for manifold,workover or drilling applications,or where access toa manual valve would bedifficult. A patented gateand seat design for wirelineshearing is available.Cameron large-bore gatevalves have sheared wirelineup to .469” and coiled tubingup to 2” in diameter.The FLS-R gate valve was developed for large-bore applications, toprovide manual operation at full working pressure with remarkablylow opening torque. The design eliminates the need for gear-typetorque multipliers, and results in quicker, safer operations.The FLS-R shares the basic features of the FLS: a slab gate, patentedseat seal, non-elastomeric stem seals, and metal-to-metal sealing.However, the FLS-R has a lower balancing stem and unique ballscrew mechanism. Advantages of the FLS-R design include:• The high efficiency, low friction, and long lead of the ball screwmechanism provide very low operating torque and a minimalnumber of turns to open the valve, even with a highdifferential pressure across the gate.• By removing the operating mechanism from the valvecavity and providing sealed retention of lubricant, the FLS-Rhas consistent operating characteristics regardless of the fluidconditions in the valve.• The rising stem and balancing stem allow no volumetric changein the cavity during stroking, eliminating pressure changes,fluid lock, and loss of grease. The dual stem design also lowersthe load on the thrust bearings to lower the torque. The lowerstem can be used as a visual position indicator.• The relative travel of the stem seal surface against the stemseal is in linear motion, reducing stem seal wear.• Either stem can be backseated to isolate or replace the stemseal with the valve under pressure.SD25393SD252556-3/8" 15,000 psi WP FLS block tree suppliedto North SeaFLS <strong>Gate</strong> Valve with Cameron Willis MHWSaf-T-Gard Wirecutting Actuator7-1/16" 10,000 psi WP FLS-R manualgate valve"Frac" Tree with 7-1/16" 10,000 psiWP FLS-R gate valveFLS-R Manual <strong>Gate</strong> Valve2 3

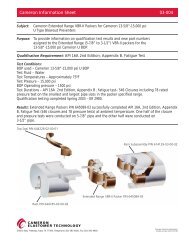

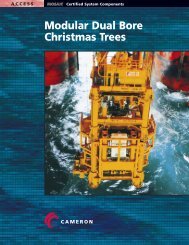

Large-Bore <strong>Gate</strong> Valves for Subsea ApplicationsProduct DevelopmentFor subsea production manifolds, flow-line isolation, and piggingloops, Cameron has supplied large-bore gate valves in various sizesand configurations. For these subsea applications, the availableoptions for actuation are:• Double-acting hydraulic actuator• FLS-R mechanism for ROV “manual” actuation• Both hydraulic and ROV manual override capability• Fail-close or fail-open hydraulic actuator• Underwater safety valve (USV) with Cameron CompactModular (CM) ActuatorFor permanent subsea installation, the FLS or FLS-R is availablewith a second resilient stem seal behind the primary pressureenergizedstem seal. Visual and/or electric position indicators areavailable as options on subsea large-bore gate valves.6-3/8" 15,000 psi WP ROV-operated FLS-R valve in hyperbaric test vesselLow-temperature (-20˚ F, -29˚ C) cycle testing of 7-1/16" 10,000 psi WPFLS-R valveAlthough internal components and design are the same as forsurface applications, valves for subsea use have sealed operatingmechanisms which have been hyperbarically tested for sealintegrity. Because the FLS-R manual (ROV) operating mechanismis separate from the valve cavity and sealed, its lubrication isretained for the life of the valve. The metal bonnet seal and stemseals have also been qualified for depths up to 10,000 feet (3048 m).Use of appropriate materials and premium hardfacings for gatesand seats ensures a long service life. FLS and FLS-R gate valves forsubsea application have been life-cycle tested to over 3500operating cycles.Cameron has completed an extensive testing program for thelarge-bore gate valve design. This includes API 6A Appendix FQualification testing, and also extensive tests to evaluatematerials. These tests include wear and friction tests todetermine the best material/coating combinations, corrosiontesting and extensive design analyses. The following indicatesCameron large-bore gate valves which have been subjected toAPI Appendix F Testing and Water Depth Simulation Tests:Appendix FPR2 Testing9” 5000 psi WP -20° F to 350° F (-29°C to176°C)7-/16” 10,000 psi WP -20°F to 350°F (-29°C to 176°C)9” 10,000 psi WP 35°F to 250°F (2°C to 121°C)6-3/8” 15,000 psi WP -20°F to 350°F (-29°C to 176°C)Water Depth Simulation Tests5-1/8” 10,000 psi WP 10,000 ft (3048 m)9” 10,000 psi WP 9000 ft (2743 m)6-3/8” 15,000 psi WP 5000 ft (1525 m)11” 5000 psi WP 3500 and 4700 ft (1067 and 1433 m)6-3/8" 15,000 psi WP FLS-R valve (foreground) and9" 10,000 psi WP FLS-R valve (background) in test facility6” x 5” psi WP Production System with FLS <strong>Gate</strong> Valvesand CM Actuators7" 10,000 psi WP FLS-R valve with hydraulic andROV actuation installed in subsea flowlineSD25036FLS <strong>Gate</strong> Valve with Double-ActingHydraulic Actuator4 5

Western HemisphereCameronPO Box 1212Houston Texas 77251-1212Tel 713 939 2211Fax 713 939 2620http://www.camerondiv.comEastern HemisphereCooper Cameron (U.K.) Ltd.5 Mondial WayHarlingtonHayes UB3 5ARTel 44 208 9901800Fax 44 208 9901888http://www.camerondiv.comAsia Pacific/Middle EastCooper Cameron (Singapore) Pte. Ltd.No. 2 Gul Circle, Jurong Industrial EstLocked Bag Service No. 3Jurong Town Post OfficeSingapore 2262Republic Of SingaporeTel 65 8613355Fax 65 8616197http://www.camerondiv.com© Cooper Cameron Corporation, Cameron Division, Printed in USA, 3/01, OL/5M, WR10063/<strong>TC1395</strong>SpoolTree and Saf-T-Gard are trademarks of the Cameron Division, Cooper Cameron Corporation