DEMO - 1956 Ford Car Shop Manual - FordManuals.com

DEMO - 1956 Ford Car Shop Manual - FordManuals.com

DEMO - 1956 Ford Car Shop Manual - FordManuals.com

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

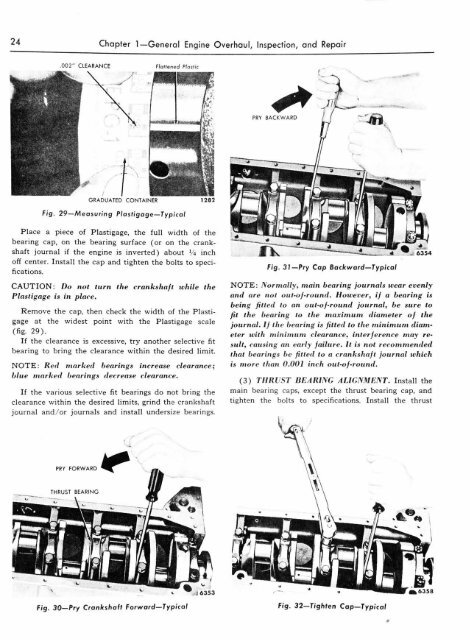

24 Chapter 1 General Engine Overhaul, Inspection, and RepairCLEARANCEFlattened PlasticGRADUATED CONTAINER1282Fig. 29 Measuring Plastigage TypicalPlace a piece ofPlastigage, the full width of thebearing cap,on the bearing surface (or on the crankshaft journal if the engine is inverted)about XA inch6354off center. Install the capfications.and tighten the bolts to speciFig. 31 Pry Cap Backward TypicalCAUTION: Do not turn the crankshaft while thePlastigage is in place.Remove the cap, then check the width of the Plastigageat the widest point with the Plastigage scale(fig- 29).If the clearance is excessive, try another selective fitbearing to bring the clearance within the desired limit.NOTE: Normally, main bearing journals wear evenlyand are not out-of-round. However, if a bearing isbeing fitted to an out-of-round journal, be sure tofit the bearing to the maximum diameter of thejournal. If the bearingis fitted to the minimum diameter with minimum clearance, interference mayresult, causing an early failure. It is not re<strong>com</strong>mendedthat bearings be fitted to a crankshaft journal whichNOTE: Redmarked bearings increase clearance;is more than 0.001 inch out-of-round.blue marked bearings decrease clearance.(3)THRUST BEARING ALIGNMENT. Install theIf the various selective fit bearings do not bring themain bearing caps, except the thrust bearing cap, andclearance within the desired limits,grind the crankshafttighten the bolts to specifications. Install the thrustjournal and/or journals and install undersize bearings.16353Fig. 30 Pry Crankshaft Forward TypicalFig. 32 Tighten Cap Typical