Your Partner for Consumables in Materials Preparation Buehler ...

Your Partner for Consumables in Materials Preparation Buehler ...

Your Partner for Consumables in Materials Preparation Buehler ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

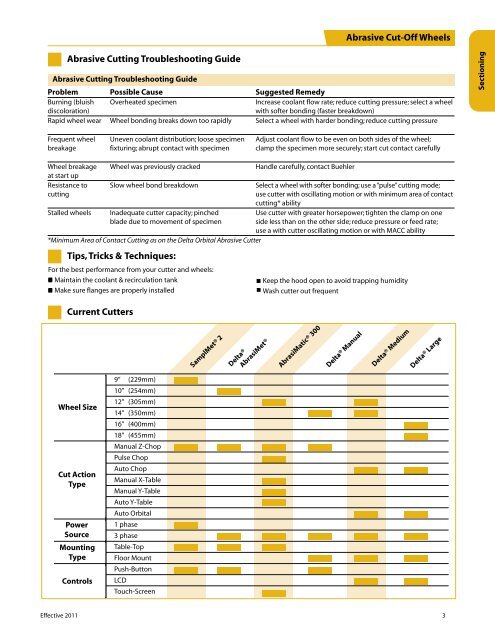

Abrasive Cutt<strong>in</strong>g Troubleshoot<strong>in</strong>g Guide<br />

Abrasive Cutt<strong>in</strong>g Troubleshoot<strong>in</strong>g Guide<br />

SamplMet® 2<br />

Delta®<br />

AbrasiMet®<br />

AbrasiMatic® 300<br />

Abrasive Cut-Off Wheels<br />

Problem Possible Cause Suggested Remedy<br />

Burn<strong>in</strong>g (bluish Overheated specimen Increase coolant flow rate; reduce cutt<strong>in</strong>g pressure; select a wheel<br />

discoloration) with softer bond<strong>in</strong>g (faster breakdown)<br />

Rapid wheel wear Wheel bond<strong>in</strong>g breaks down too rapidly Select a wheel with harder bond<strong>in</strong>g; reduce cutt<strong>in</strong>g pressure<br />

Frequent wheel Uneven coolant distribution; loose specimen Adjust coolant flow to be even on both sides of the wheel;<br />

breakage fixtur<strong>in</strong>g; abrupt contact with specimen clamp the specimen more securely; start cut contact carefully<br />

Wheel breakage Wheel was previously cracked Handle carefully, contact <strong>Buehler</strong><br />

at start up<br />

Resistance to Slow wheel bond breakdown Select a wheel with softer bond<strong>in</strong>g; use a “pulse” cutt<strong>in</strong>g mode;<br />

cutt<strong>in</strong>g use cutter with oscillat<strong>in</strong>g motion or with m<strong>in</strong>imum area of contact<br />

cutt<strong>in</strong>g* ability<br />

Stalled wheels Inadequate cutter capacity; p<strong>in</strong>ched Use cutter with greater horsepower; tighten the clamp on one<br />

blade due to movement of specimen side less than on the other side; reduce pressure or feed rate;<br />

use a with cutter oscillat<strong>in</strong>g motion or with MACC ability<br />

*M<strong>in</strong>imum Area of Contact Cutt<strong>in</strong>g as on the Delta Orbital Abrasive Cutter<br />

Tips, Tricks & Techniques:<br />

For the best per<strong>for</strong>mance from your cutter and wheels:<br />

■ Ma<strong>in</strong>ta<strong>in</strong> the coolant & recirculation tank<br />

■ Make sure flanges are properly <strong>in</strong>stalled<br />

Current Cutters<br />

Wheel Size<br />

Cut Action<br />

Type<br />

Power<br />

Source<br />

Mount<strong>in</strong>g<br />

Type<br />

Controls<br />

9” (229mm)<br />

10” (254mm)<br />

12” (305mm)<br />

14” (350mm)<br />

16” (400mm)<br />

18” (455mm)<br />

Manual Z-Chop<br />

Pulse Chop<br />

Auto Chop<br />

Manual X-Table<br />

Manual Y-Table<br />

Auto Y-Table<br />

Auto Orbital<br />

1 phase<br />

3 phase<br />

Table-Top<br />

Floor Mount<br />

Push-Button<br />

LCD<br />

Touch-Screen<br />

■ Keep the hood open to avoid trapp<strong>in</strong>g humidity<br />

Wash cutter out frequent<br />

Delta® Manual<br />

Delta® Medium<br />

Delta® Large<br />

Effective 2011 3<br />

Section<strong>in</strong>g