Conductor Sharing Wellhead - cedip

Conductor Sharing Wellhead - cedip

Conductor Sharing Wellhead - cedip

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

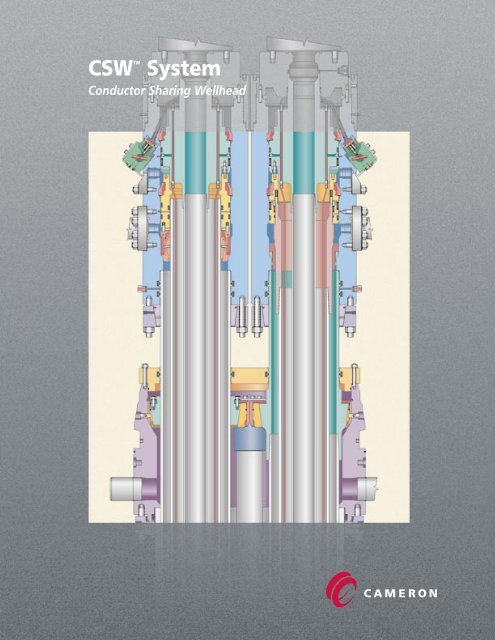

CSW System<strong>Conductor</strong> <strong>Sharing</strong> <strong>Wellhead</strong>

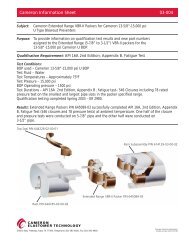

<strong>Conductor</strong> <strong>Sharing</strong> <strong>Wellhead</strong>CSW DevelopmentBefore the CSW was introduced,typical platform wellheads allowedfor one well per slot. Each wellcould produce from multiplezones, but if one zone neededworkover, the entire well wasworked over. These systems usedflanged connections and spooltypewellheads.The Cameron CSW System integrates two or morewellhead systems into a single conductor. Major benefitsinclude:• Smaller platform sizes and maximized use of existingplatform slots.• Lower site development costs in land applications.• Reduced installation times.• Independent drilling and completion of each well allowswell access with decompletion of the adjacent well.• Commitment to the second (or third) well is notnecessary at the same time as the first well.11” Nominal CSW with Dual andSingle Christmas Trees Installed.Next, unitized wellheads incorporatedcasing and tubing stageswithin a common housing. Thisreduced the number of connectionsand was more economical.However, these systems couldaccommodate only one well perconductor.In the early 1990s, systems wereintroduced allowed two wells tobe drilled in one conductor.These systems utilized spool-typewellheads, separation was downholeand both wells were drilledand completed simultaneously.Today, the Cameron CSW offersa combination of systems whichallow up to three independentdual completions in one conductor.Each well can be drilled and completedindependently, the numberof connections is minimized, thesystem is compact, safe and fieldproven. The best of all solutions.Field-Proven TechnologyCameron has installed a large number of CSW systemsin various parts of the world. These include the first everinstallation of both a single and dual completion in a 30”conductor. Future installations call for three dual completionsinside a 36” conductor and two 9” completions in asingle conductor.The success of Cameron’s CSW wellhead system lieslargely in its use of standard components and otherCameron-exclusives such as the CAMFORGE andSlipLock Connection Systems which provide quickmake-up connections without welding.SSMC <strong>Wellhead</strong> Reduces HeightThe CSW wellhead uses standard components fromCameron’s highly successful Standard Snapring ModularCompact (SSMC) <strong>Wellhead</strong> System. All componentsabove the surface casing strings are standard, field-provenSSMC components including the casing hangers, sealassemblies and tubing hangers. The unitized CSW housingallows for installation of the casing hangers, seal assembliesand tubing hangers in a single housing. In addition,all equipment on each completion is identical, reducinginventory, saving on installation time and reducingpotential operational problems.CSW <strong>Wellhead</strong> with Workover RiserInstalled Over One wellFast Make-Up, No Weld ConnectionsCameron’s CAMFORGE and SlipLock connectionsystems are used on the CSW wellhead to reduceinstallation time and eliminate the need for welding. The popular CAMFORGEsystem uses a “cold forging” technique to secure a metal-to-metal connection thatmakes installation fast, safe and economical. The SlipLock system uses a simpleslip-type mechanism to replace conventional casing threads or slip-on preparations,which require field welding.11” Nominal CSW <strong>Wellhead</strong> andCAMFORGE Connection System

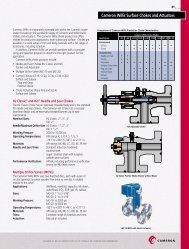

4 1 /16” Bore BlockChristmas Tree ValveSSMC Tubing HangerSSMC Seal AssemblyCSW Housingwith CAMFORGEBottom ConnectionSSMC Casing Hanger30” <strong>Conductor</strong>13 3 /8” Well Centralizer9 5 /8” Casing7 5 /8” Casing4 1 /2” Tubing11” Nominal CSW System

Tubing Head AdapterSSMC Single TubingHangerSSMC EmergencySeal AssemblySSMC Seal AssemblySSMC EmergencySlipsSSMC Casing Hanger13 5 /8” CSW Housingwith SlipLock BottomConnectionEmergencyStandardDiverter HousingSlipLock Connector36” <strong>Conductor</strong>13 3 /8” Casing9 5 /8” Casing3 1 /2” TubingSD01674613 5 /8” Nominal CSW System

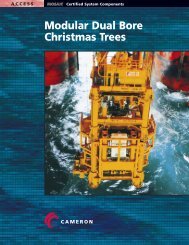

Cameron <strong>Conductor</strong> <strong>Sharing</strong> <strong>Wellhead</strong> systems can save up to 20% on individualwell costs. Additional savings can be realized from reduction in platformsize and more efficient use of well conductor slots. Cost and efficiency savingscome from the following benefits of the Cameron CSW:Optimized Platform Space• One, two or three independent wells in each platform slot.• Each well may contain single or dual completion.• Compact design does not required multi-level platform.Typical CSW Installation FeaturesStep 1The centralizerfor thefirst well isinstalled.Reduced Rig TIme• Drilling and completion are independent between the wells.• Commitment to second (or third) well is not required prior to spuddingfirst well.• Each well can be worked over independently.• Fewer connections than spool-type wellhead.• Conventional drilling and completion procedures.Enhanced Safety• Reduced number of BOP connections.• Through BOP/diverter operations.• Fast make-up, weldless CAMFORGE and SlipLock connectors are available.Reduced Inventory• Identical components for each well.• Modular design, interchangeable components.• Single compact housing for each well.Flexibility• Wide range of casing programs available.Field-Proven• Uses popular Cameron Snapring Modular Compact (SSMC) <strong>Wellhead</strong>systems on each well.• Many CSW systems installed and operating in different areas of the world.Step 3Drill outfor surfacecasing withdivertercontrol.Step 5CamforgeCSWhousingsinstalled onboth sides.Step 2Both wellcentralizersare installed.Step 4Riser installedfor secondwell againstcompletedfirst weld.Step 6Both wellscompletedwith 41/165000 psi WPvalvesinstalled.Cameron CSW Systems accommodate two or more wells with any combination or single and dual completions

Western HemisphereCameronPO Box 1212Houston Texas 77251-1212Tel 713 939 2211Fax 713 939 2620http://www.camerondiv.comEastern HemisphereCooper Cameron (U.K.) Ltd.5 Mondial WayHarlingtonHayes UB3 5ARTel 44 208 9901800Fax 44 208 9901888http://www.camerondiv.comAsia Pacific/Middle EastCooper Cameron (Singapore) Pte. Ltd.No. 2 Gul Circle, Jurong Industrial EstLocked Bag Service No. 3Jurong Town Post OfficeSingapore 2262Republic Of SingaporeTel 65 8613355Fax 65 8616197http://www.camerondiv.com© Cooper Cameron Corporation, Cameron Division, Printed in USA, 9/99, TG/5M, WR10027/TC1387