Lighting Electronics | 2007/08 - National Lamps and Components

Lighting Electronics | 2007/08 - National Lamps and Components

Lighting Electronics | 2007/08 - National Lamps and Components

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

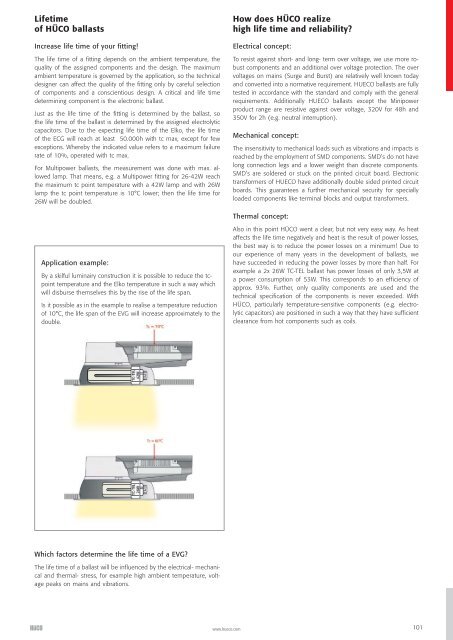

Lifetimeof HÜCO ballastsIncrease life time of your fitting!The life time of a fitting depends on the ambient temperature, thequality of the assigned components <strong>and</strong> the design. The maximumambient temperature is governed by the application, so the technicaldesigner can affect the quality of the fitting only by careful selectionof components <strong>and</strong> a conscientious design. A critical <strong>and</strong> life timedetermining component is the electronic ballast.Just as the life time of the fitting is determined by the ballast, sothe life time of the ballast is determined by the assigned electrolyticcapacitors. Due to the expecting life time of the Elko, the life timeof the ECG will reach at least 50.000h with tc max, except for fewexceptions. Whereby the indicated value refers to a maximum failurerate of 10%, operated with tc max.For Multipower ballasts, the measurement was done with max. allowedlamp. That means, e.g. a Multipower fitting for 26-42W reachthe maximum tc point temperature with a 42W lamp <strong>and</strong> with 26Wlamp the tc point temperature is 10°C lower; then the life time for26W will be doubled.How does HÜCO realizehigh life time <strong>and</strong> reliability?Electrical concept:To resist against short- <strong>and</strong> long- term over voltage, we use more robustcomponents <strong>and</strong> an additional over voltage protection. The overvoltages on mains (Surge <strong>and</strong> Burst) are relatively well known today<strong>and</strong> converted into a normative requirement. HUECO ballasts are fullytested in accordance with the st<strong>and</strong>ard <strong>and</strong> comply with the generalrequirements. Additionally HUECO ballasts except the Minipowerproduct range are resistive against over voltage, 320V for 48h <strong>and</strong>350V for 2h (e.g. neutral interruption).Mechanical concept:The insensitivity to mechanical loads such as vibrations <strong>and</strong> impacts isreached by the employment of SMD components. SMD’s do not havelong connection legs <strong>and</strong> a lower weight than discrete components.SMD’s are soldered or stuck on the printed circuit board. Electronictransformers of HUECO have additionally double sided printed circuitboards. This guarantees a further mechanical security for speciallyloaded components like terminal blocks <strong>and</strong> output transformers.Thermal concept:Application example:By a skilful luminairy construction it is possible to reduce the tcpointtemperature <strong>and</strong> the Elko temperature in such a way whichwill disburse themselves this by the rise of the life span.Is it possible as in the example to realise a temperature reductionof 10°C, the life span of the EVG will increase approximately to thedouble.Also in this point HÜCO went a clear, but not very easy way. As heataffects the life time negatively <strong>and</strong> heat is the result of power losses,the best way is to reduce the power losses on a minimum! Due toour experience of many years in the development of ballasts, wehave succeeded in reducing the power losses by more than half. Forexample a 2x 26W TC-TEL ballast has power losses of only 3,5W ata power consumption of 53W. This corresponds to an efficiency ofapprox. 93%. Further, only quality components are used <strong>and</strong> thetechnical specification of the components is never exceeded. WithHÜCO, particularly temperature-sensitive components (e.g. electrolyticcapacitors) are positioned in such a way that they have sufficientclearance from hot components such as coils.Which factors determine the life time of a EVG?The life time of a ballast will be influenced by the electrical- mechanical<strong>and</strong> thermal- stress, for example high ambient temperature, voltagepeaks on mains <strong>and</strong> vibrations.www.hueco.com 101